Data connection line

A technology of data connection wires and wires, which is applied in the direction of connection, parts of connection devices, electrical components, etc., which can solve problems such as difficult processing, unqualified finished product quality, and prone to defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

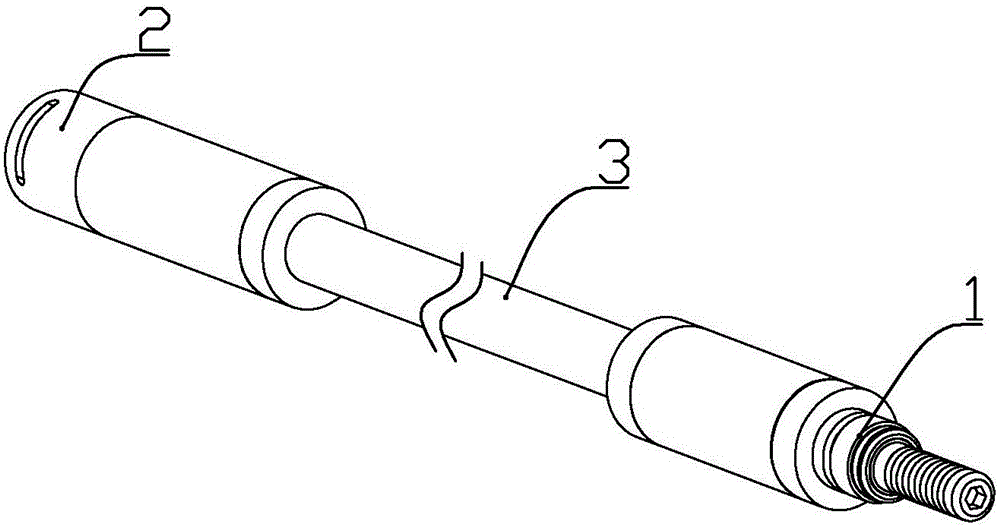

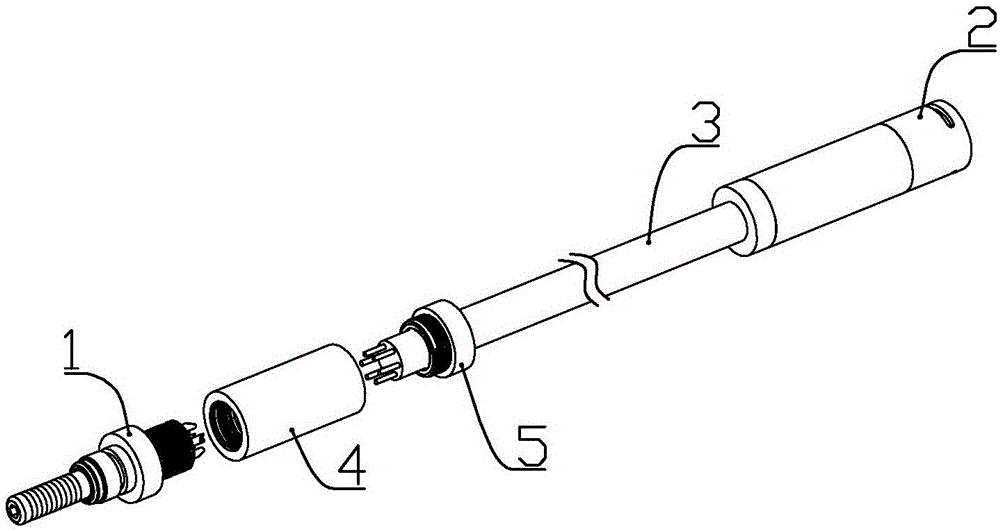

[0058] according to Figure 1 to Figure 24 As shown, this embodiment is a data connection cable, including a wire 3 , a male connector 1 arranged at one end of the wire and a female connector 2 arranged at the other end of the wire.

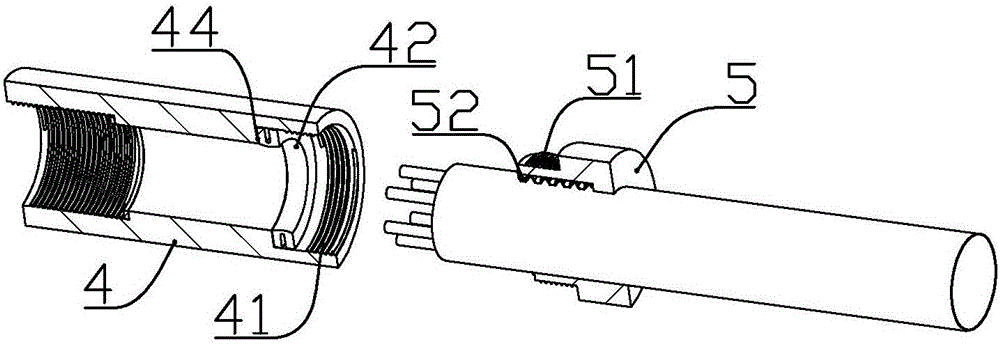

[0059] The position close to the end of the wire 3 is covered with a threaded cable joint 5 and a locking nut 4, the outer wall of one end of the cable joint 5 is formed with an external thread a51, and the inner wall of one end of the locking nut 4 is formed There is an internal thread a41 cooperating with the external thread a51; a rubber ring positioning shoulder 44 is formed in the lock nut 4 adjacent to the internal thread a41, and the rubber ring positioning shoulder 44 is formed inside the lock nut. A U-shaped rubber ring 42 is installed between the end of the cable joint.

[0060] The outer circumference of the U-shaped rubber ring is sealed against the inner wall of the locking nut, and the inner circumference of the U-shaped rubber rin...

Embodiment 2

[0092] In this embodiment, on the basis of Embodiment 1, the following improvements are made: the end electrode tip 141 of the end electrode 14 is axially formed with a glue overflow hole that communicates with the glue injection groove on the insulating cylinder, When injecting glue through the glue injection port on the locking piece, the locking piece is facing down, the end electrode head is facing up, the glue flows into the glue injection groove along the glue injection channel, until the glue overflows from the glue overflow through hole Note that the glue injection tanks are all filled with glue, just scrape off the glue on the outer surface of the end electrode head before the glue solidifies.

[0093] In addition, both ends of each electrode ring a are tapered slopes with a high outer circumference and a lower inner circumference, so that the electrode ring a can closely fit with the outer circumference of the adjacent insulating ring without gaps between the two. Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com