Packaging device for a light-transmitting carrier and an electroluminescent device

A technology of electroluminescent devices and packaging devices, which is applied to semiconductor devices, electrical components, circuits, etc., and can solve problems such as deformation of glass substrates or PET films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

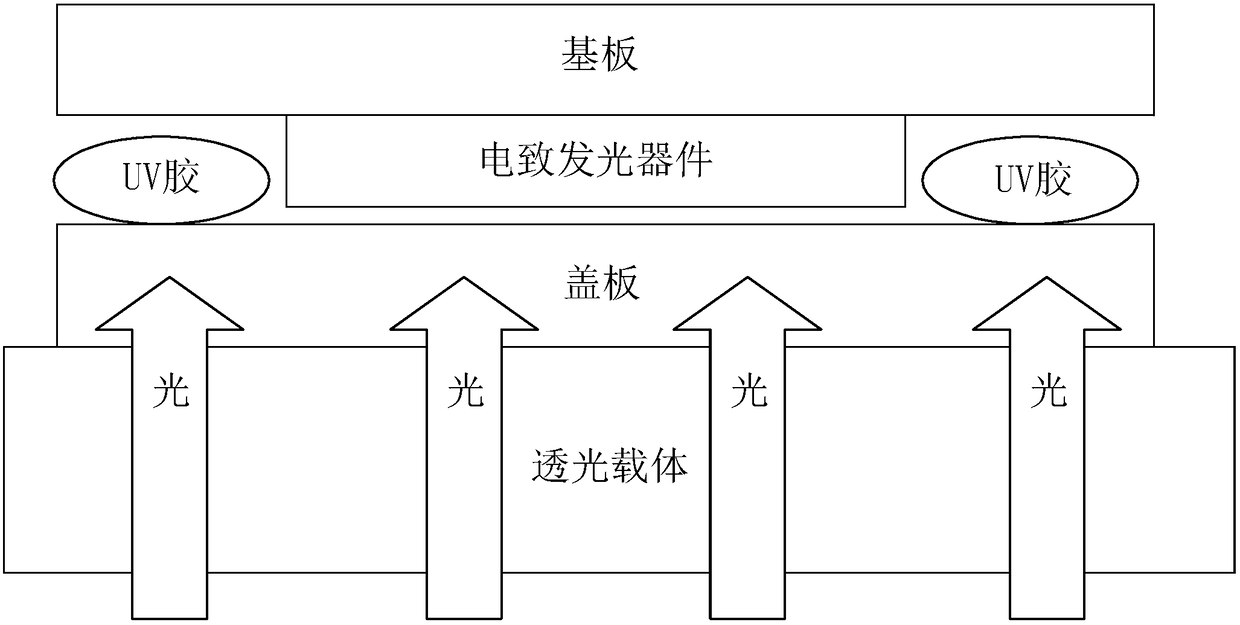

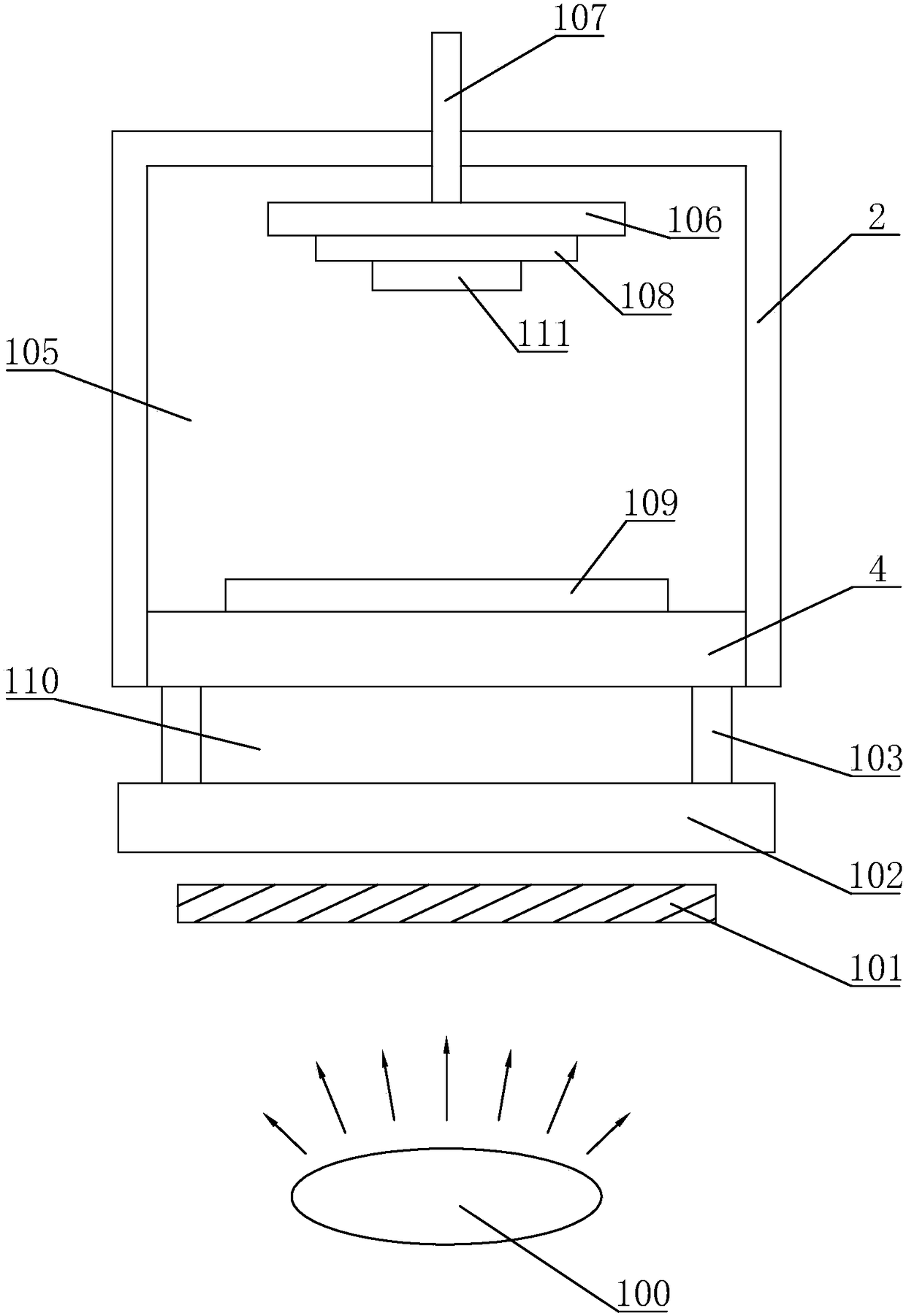

[0043] like figure 2 A packaging device for an electroluminescent device is shown, including a light source 100, a cover part 2, an adsorption tool 106, a heat insulation component 110, a second light-transmitting plane carrier 102, a transport mechanism 107 for driving the adsorption tool 106, and negative pressure adsorption The light-transmitting carrier 4 is formed between the cover part 2 and the light-transmitting carrier 4 to form a sealed space 105 for packaging the electroluminescent device.

[0044] The movable cover part 2 is used to open and close the sealed space 105 of the packaging device, and the transportation mechanism 107 drives the suction tool 106 to move the electroluminescent device to the suction surface of the transparent carrier 4 for packaging and suction correction.

[0045] The cover part 2 is provided with a pressure regulating port, and the air pressure in the sealed space 105 is adjusted by connecting a negative pressure device (which can be a co...

Embodiment 2

[0070] Compared with Embodiment 1, this embodiment differs in that: the structure of negative pressure voids of the light-transmitting carrier 4 is different.

[0071] like Figure 7 to Figure 9 As shown, the negative pressure gaps on the surface of the transparent carrier 4 in this embodiment are grooves 42 , and the grooves 42 are distributed in a closed ring along the outer periphery of the transparent carrier. The negative pressure port 40 communicates with the grooves 42 through the airflow channel 41 .

[0072] Similarly, the groove 42 is also distributed in the non-display area of the light-transmitting carrier 4. The groove 42 can be single or multiple. The groove in this embodiment is an annular groove 42, and along the non-display Arranging the inner and outer periphery of the area can meet the basic needs of adsorption correction.

[0073] By extracting air from the negative pressure interface 40 , a negative pressure is generated in the entire annular groove 42 ...

Embodiment 3

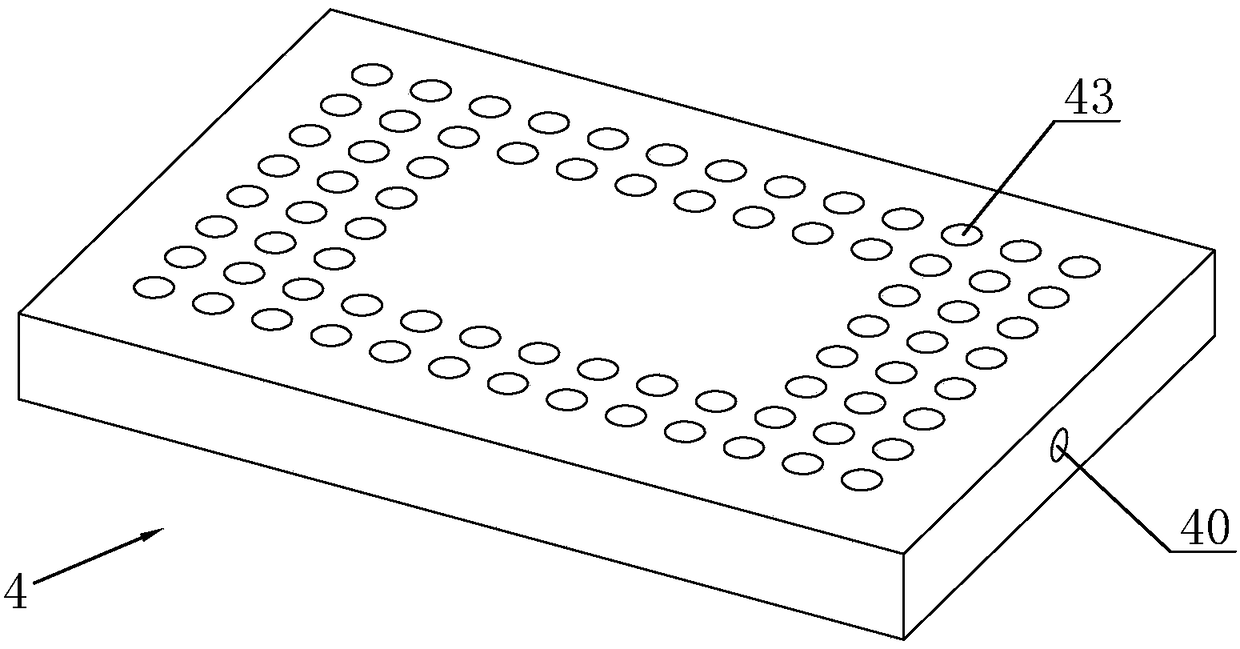

[0078] like Figure 10 and Figure 11 As shown, this embodiment is a combination of Embodiment 1 and Embodiment 2. The adsorption surface of the light-transmitting carrier 4 has both an annular groove 42 and a negative pressure through hole 43, wherein the groove 42 and the negative pressure through hole 43 are both In the non-display area of the snap surface.

[0079] like Figure 10 As shown, the negative pressure through holes 43 are located in the groove 42. The groove 42 is in the shape of a square ring. in the non-display area.

[0080] Compared with the embodiment 1, the groove 42 has a better adsorption effect on the edge periphery of the cover plate in this embodiment, and the cover plate is not easy to fall off. Compared with the second embodiment, the negative pressure through hole 43 also makes up for the lack of adsorption inside the cover plate in this embodiment. It is equivalent to concentrating the advantages of Embodiment 1 and Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com