Evaluation method of oil casing quality level

A technology of quality level and evaluation method, which is applied in the direction of instruments, calculations, electrical digital data processing, etc., can solve the problems that cannot comprehensively reflect the product quality level, and achieve the effect of reasonable and accurate evaluation

Active Publication Date: 2018-11-30

BC P INC CHINA NAT PETROLEUM CORP +2

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, these indicators can only reflect the average level or degree of dispersion of the batch of data alone, and cannot comprehensively reflect the product quality level, making it difficult to provide more direct and objective references for oilfield customers when purchasing oil casings

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example

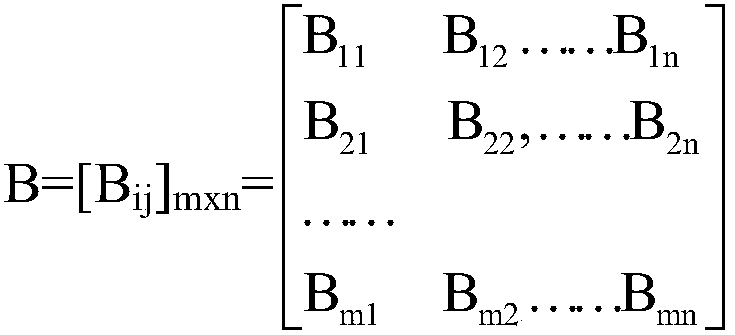

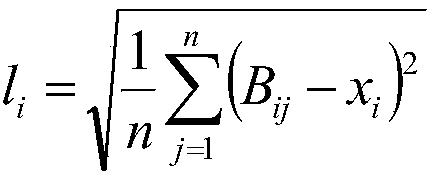

[0064] The quality level evaluation was carried out for a batch of qualified 139.70×7.72mm P110 BC casings shipped from a certain factory. There were 24 batches of casings in this batch. 20 bushings were randomly selected for performance parameter testing, and the top 20 heat batches were selected for physical and chemical properties. The performance parameters are determined as follows:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

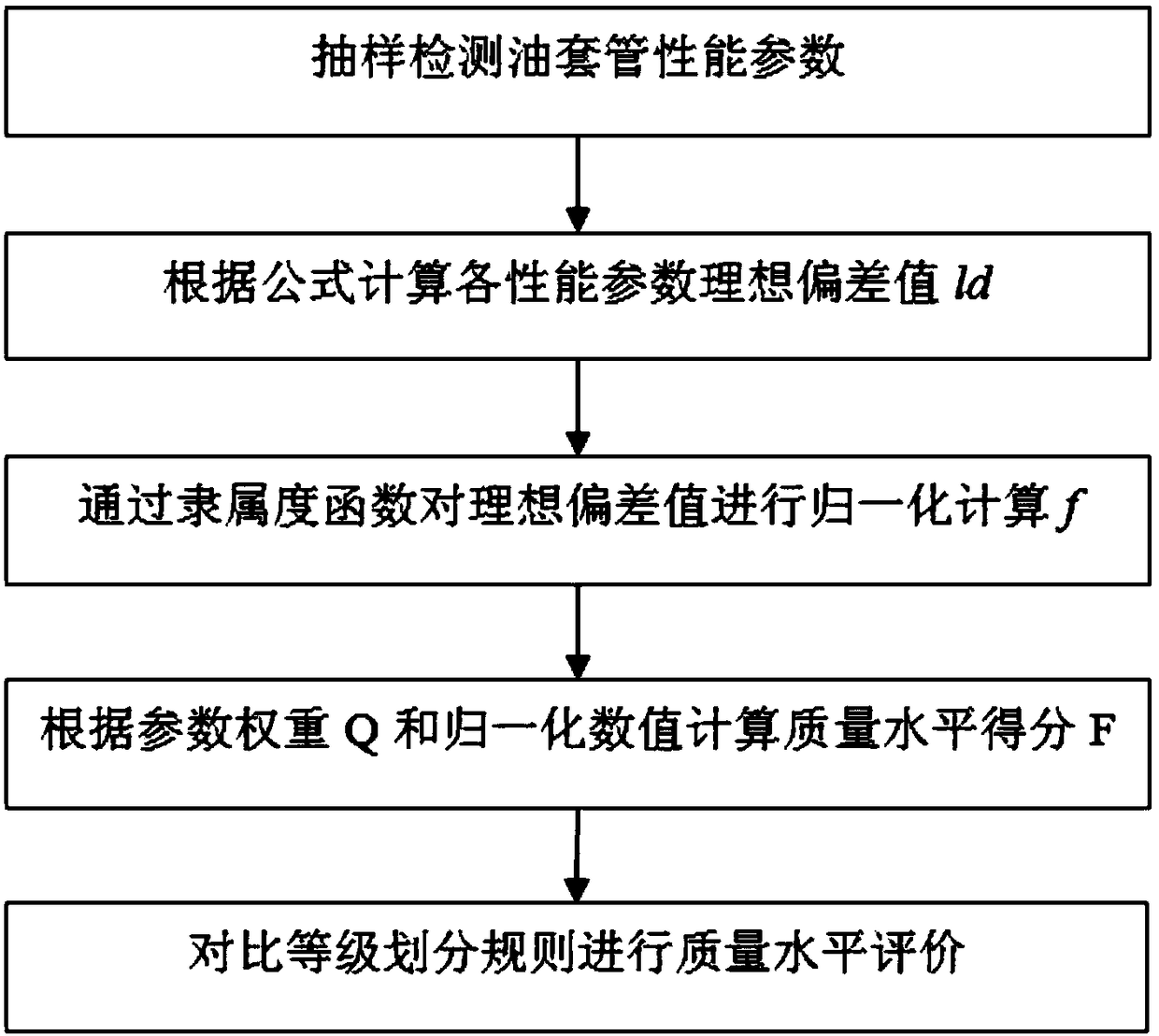

The invention provides an oil casing quality level evaluation method. The method comprises the following steps of: randomly drawing n oil casings and detecting m performance parameters of each drawn oil casing; carrying out an ideal deviation value of each performance parameter; calculating a normalization score of the ideal deviation value of each performance parameter; calculating a quality level score of the n oil casings; and determining a quality level evaluation result of the n oil casings according to the quality level score of the n oil casings. The oil casing quality level evaluation method provided by the invention not only can be used for reflecting the degrees, to an ideal target value, of performance parameter detection data, but also can be used for reflecting statistic indexes of discrete degrees of the performance parameter detection data, so as to evaluate the oil casing quality level more objectively, reasonably and correctly, and provide reference for oil field customers during the purchase.

Description

technical field [0001] The invention relates to the technical field of evaluating the quality level of oil and casing pipes in the petroleum and natural gas industry, in particular to a method for evaluating the quality level of oil and casing pipes. Background technique [0002] Oil casing is an important material and equipment used in the exploitation of oil and gas fields, and its quality directly affects the production safety and production efficiency of oil and gas fields. At present, most of the tubing and casing used in major oil fields implement API-related standards, such as API 5CT and API 5B. There are also oil casings that use non-API specifications, such as European Mannesmann V·M, American Hunting Hunting, American Hydril, Argentina Tenaris and other companies have developed their own special oil casings, all of which implement their special oil casing standards. Regardless of API oil casing or non-API oil casing, the implemented standards have clear requireme...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G06F17/50

CPCG16Z99/00

Inventor 闫凯赵新伟王长安杨专钊杨红兵李昱坤卫栋王冬林田新新

Owner BC P INC CHINA NAT PETROLEUM CORP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com