Workpiece drying device

A drying device and workpiece technology, which is applied in drying, drying machine, drying gas arrangement and other directions, can solve the problems of increasing workpiece loading and unloading, reducing production efficiency, affecting production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

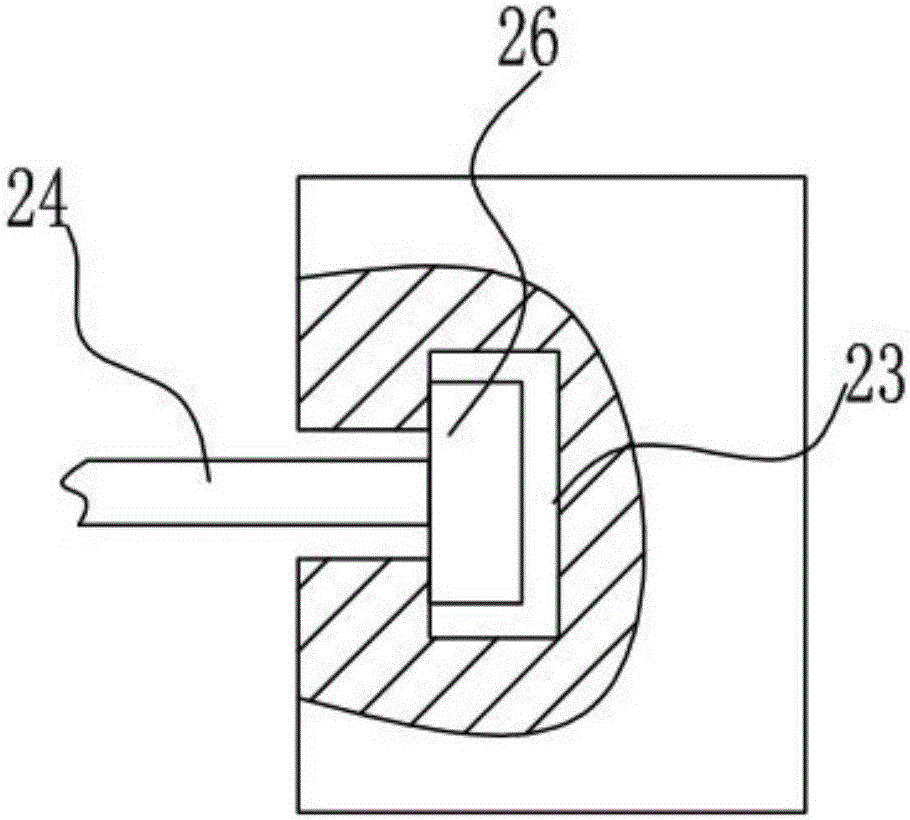

[0015] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a workpiece drying device includes a frame, the upper part of the frame is provided with a guide rail 1, a sliding seat 2 is slidably installed on the guide rail 1, and a vertical bar is provided on the lower surface of the sliding seat 2 3. A mounting base 4 is installed on the lower end of the vertical rod 3, and a drying shell 5 is also installed on the frame, and an exhaust fan 27 is arranged inside the drying shell 5, and the drying shell 5 There is a feed port 6 and a discharge port 7, the guide rail 1 enters the drying shell 5 from the feed port 6 and extends out of the guide rail from the discharge port 7, and the mounting seat The outer periphery of 4 is hinged with a plurality of swing rods 8, and the swing rods 8 are connected with a swing driving device that drives the swing rods 8 to deflect so that the lower ends of each of the swing rods 8 approach or separate from each other, and each of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com