A roof paint spraying machine

A technology of spraying machine and coating machine, which is applied in construction, building structure and other directions, can solve the problems of low equipment efficiency, low coating utilization rate, low stepping efficiency, etc., to save labor costs, high coating utilization rate, automation high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

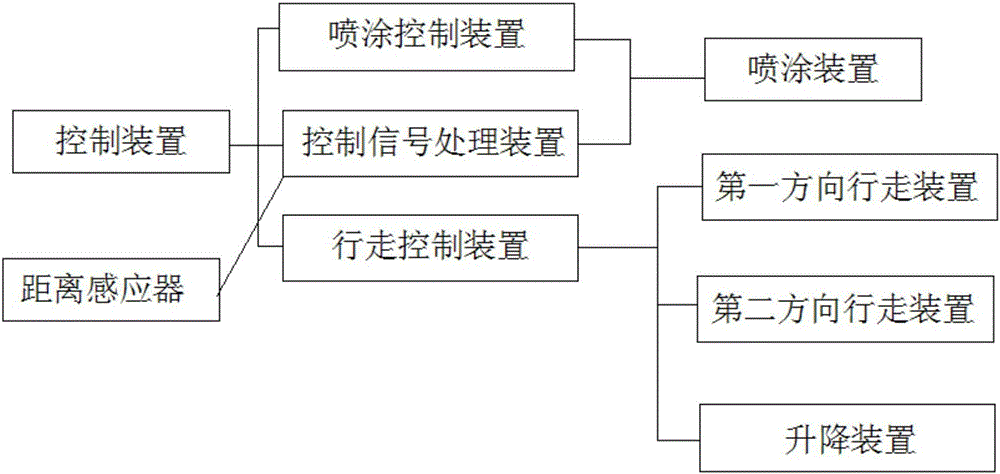

[0039] The user uses the present invention to place the column 2 on the four corners of the room to be sprayed. The column 2 is connected to the paint machine body 1 through the walking device 3. The walking device 3 includes a first direction walking device 4 and a second direction walking device 5. The walking device 4 in one direction is connected with the walking device 5 in the second direction. When the user needs to spray the ceiling, the distance sensor 14 arranged on the paint machine body 1 detects the walking device 4 in the first direction and the walking device 5 in the second direction and / or the ceiling. and / or the position distance of the corner of the wall, the detected data is sent to the control signal processing device 17 in the control device 9, and at the same time, the walking control device 16 in the control device 9 controls the first direction walking device 4 and / or The second direction walking device 5 and / or lifting device 7 walks or lifts, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com