High-strength combined type drain plate

A combined drainage board technology, applied in roof drainage, construction, infrastructure engineering, etc., can solve the problems of simple structure of drainage board, inability to connect tightly, affecting the load strength of drainage board, etc., to achieve good practicability and simple manufacturing process , Improve the effect of working strength and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

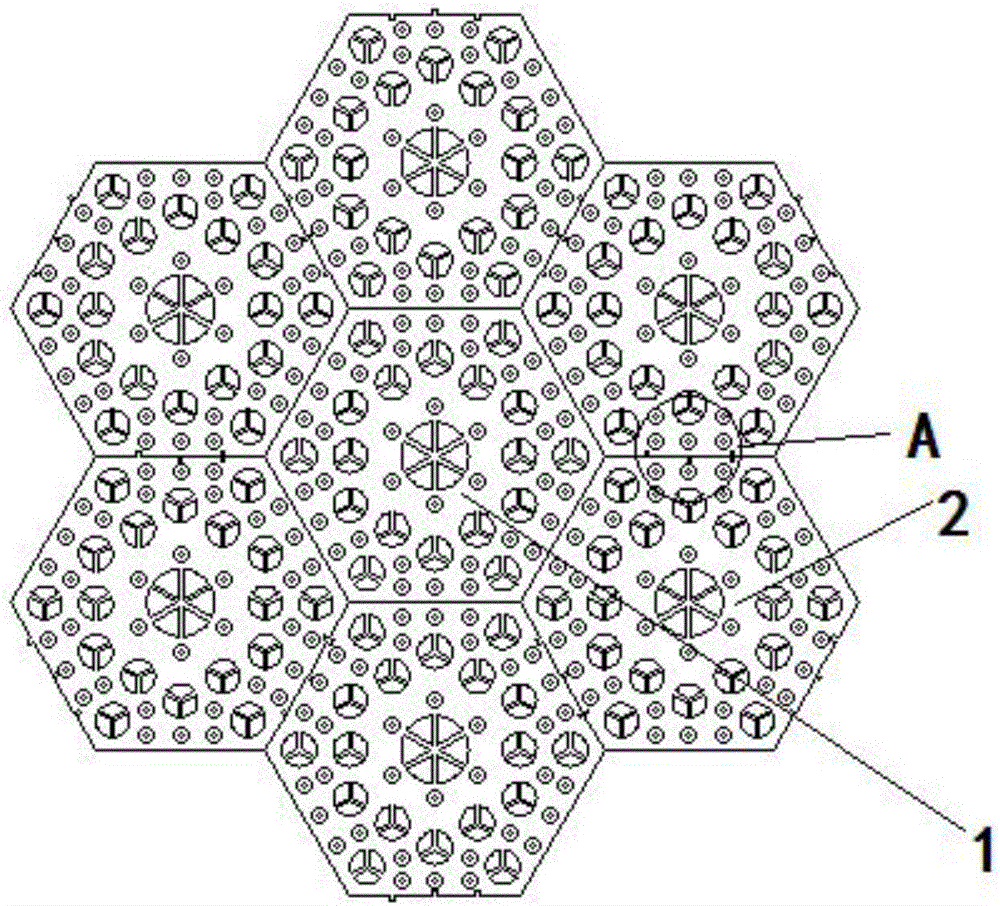

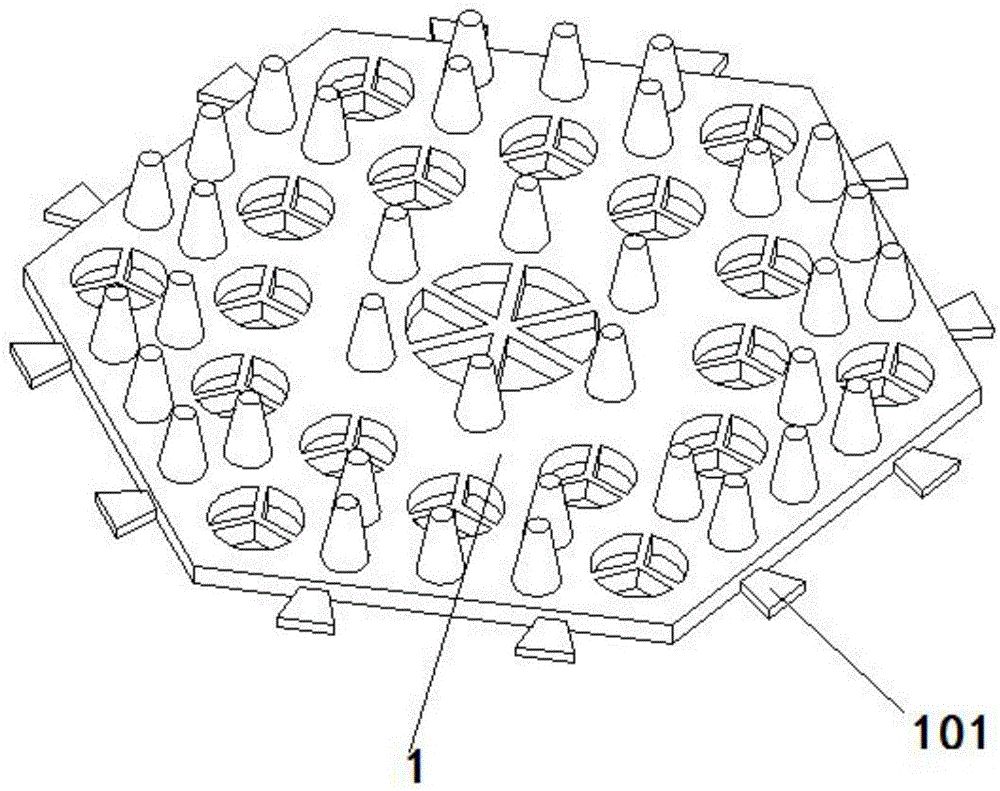

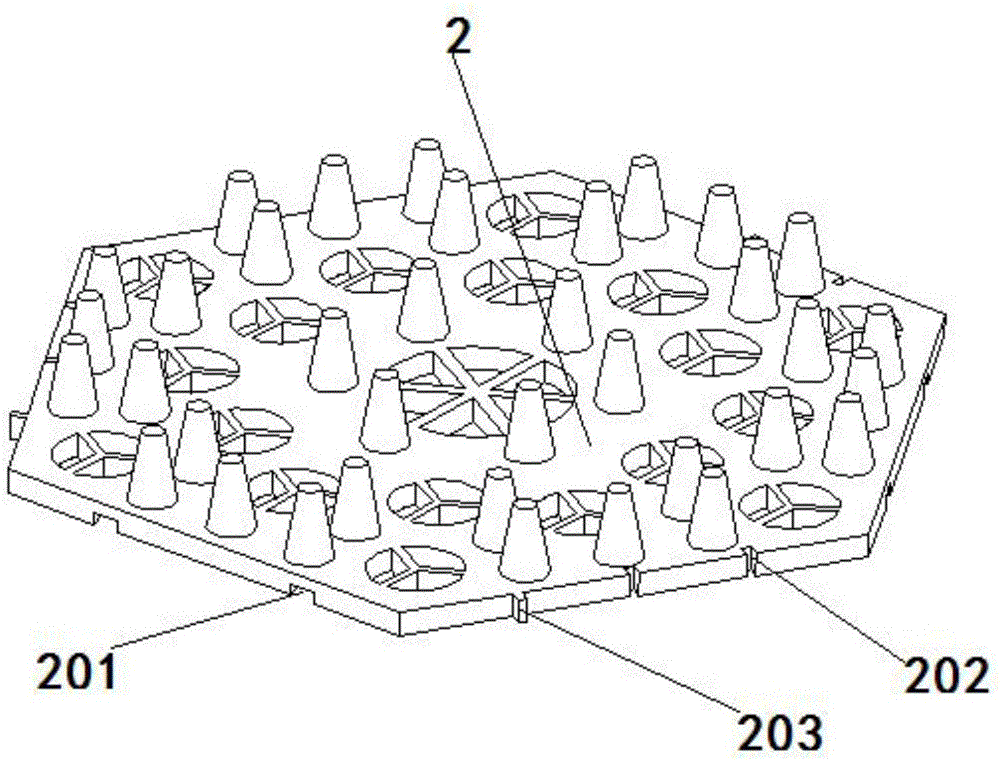

[0028] Such as Figure 1 to Figure 8 A high-strength combined drainage board is shown, including a main board 1 and an auxiliary board 2;

[0029] The main board 1 has a regular hexagonal structure, a first through hole 102 is opened at the center of one side surface, and a second through hole 104 is opened at the center of the connecting line between the center of the first through hole 102 and the six side edges of the main board 1. There is a third through hole 103 at the center of the connecting line between the center of the two through holes 104 and the six side edges of the main board 1, and a fourth through hole 105 at the center of the triangle formed by the center of the first through hole 102 and the sides of the main board 1. ;

[0030] A first boss 106 is fixed at the center of the line connecting the center of the thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com