Under-pressure balance pile forming method for control modulus pile

A technology of pressure balance and modulus piles, which is applied in the direction of sheet pile walls, foundation structure tests, construction, etc., can solve problems such as broken piles, uneven pile formation of long piles, and restrictions on the in-depth development of composite foundation theory and practice. Ensure the quality of the pile and ensure the uniformity of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

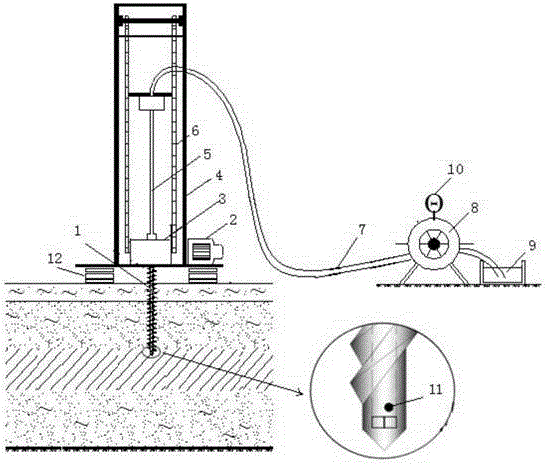

[0013] Such as figure 1 Shown: a control modulus pile forming equipment, which consists of a drill bit 1, a motor 2, a control platform 3, a drill frame 4, a drill pipe 5, a transmission chain 6, a slurry pipe 7, a concrete pump 8, a concrete pool 9, belt The pressure balance control valve 10, the pressure sensor 11, and the crawler belt 12 that the drilling rig moves, wherein the drill bit 1 and the drill pipe 5 are provided with longitudinal through holes, and the output port of the concrete pump 8 passes through the upper end of the slurry pipe 7 and the drill pipe 5. The lower part of the drill pipe 5 is connected with the control platform 3, and the control platform 3 is fixed on the base of the drilling rig. They are respectively connected to the left and right sides of the control platform 3, the motor 2 is fixed on the base of the drilling rig, the transmission shaft of the motor 2 is linked with the transmission chain 6 and the driving part of the control platform 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com