Periodic directional flow guide device for a plurality of fluids

A diversion device, periodic technology, applied in the direction of valve devices, multi-way valves, mechanical equipment, etc., can solve the load limit and other problems, and achieve the effect of easy sealing, small diameter and small sealing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

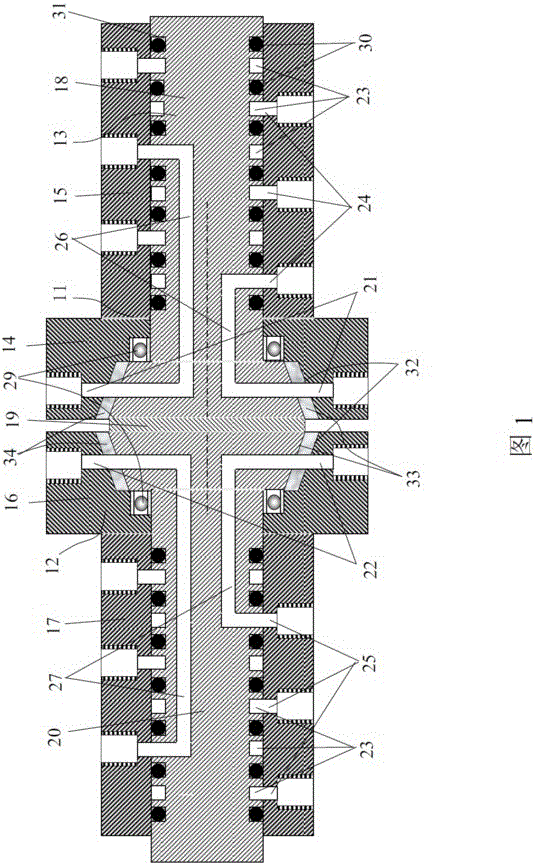

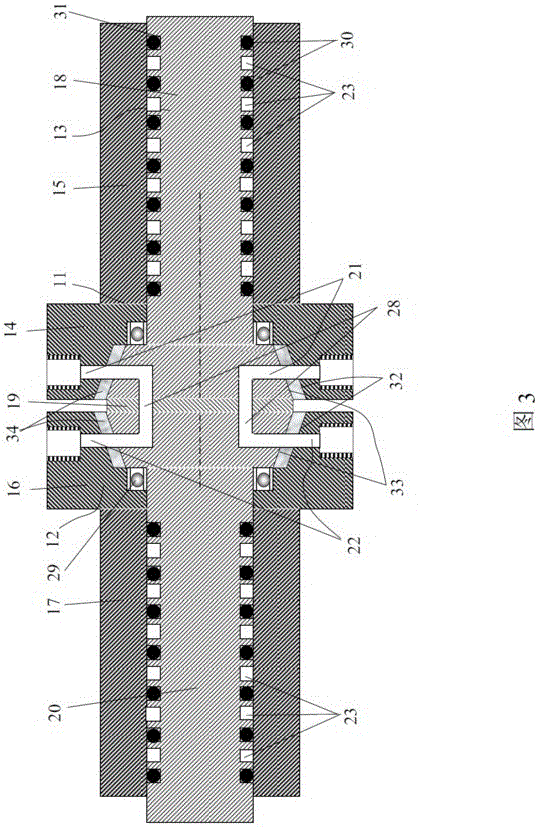

[0036] Such as figure 1As shown, the present invention includes stators 11, 12 and rotor 13, wherein the first stator 11 includes a disc member 14 and a cylindrical tube member 15, and the second stator 12 includes a disc member 16 and a cylindrical tube member 17 The rotor 13 is a cylinder 18-double cone 19-cylinder 20 structure, and the rotor 13 is positioned on the stator cylindrical tube parts 15 and 17 by the bearing 29, and is rotatably arranged in the circle surrounded by the first stator 11 and the second stator 12 inside the space.

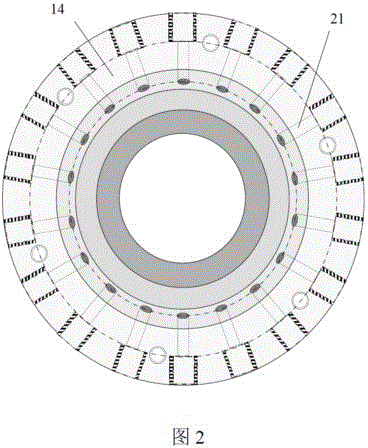

[0037] A plurality of stator distribution passages 21 are arranged inside the first stator disk part 14, and each stator distribution passage 21 is radially evenly distributed in the same section of the first stator disk part 14 (such as figure 2 As shown), each stator distribution channel 21 forms two opening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com