A high-altitude ignition-starting missile engine

A technology of engines and starter motors, which is applied in the direction of machines/engines, mechanical equipment, gas turbine devices, etc., can solve the problems of high-altitude ignition and starting of bomb aviation turbojet and turbofan engines, and solve the problem of high-altitude ignition and starting, significantly The effect of engineering application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

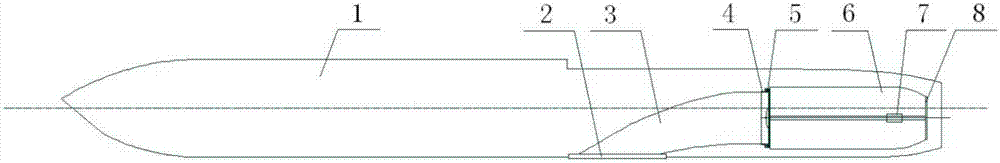

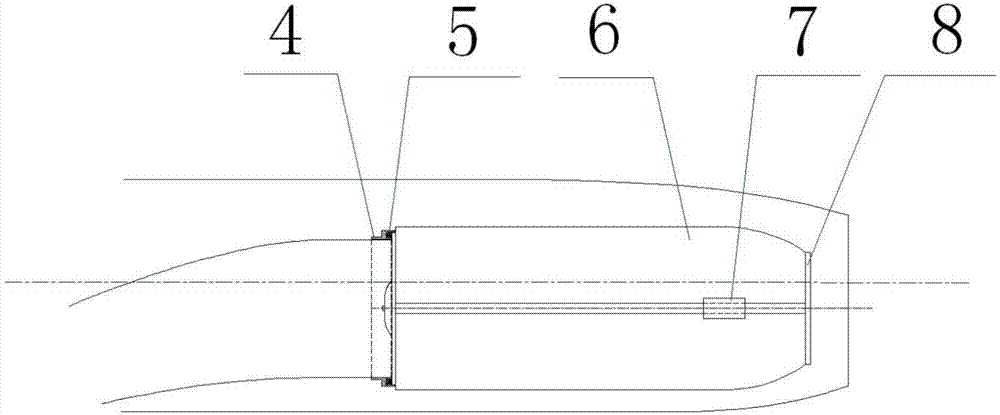

[0014] Such as Figure 1-3 Shown, a kind of high-altitude ignition start bomb engine, described high-altitude ignition start bomb engine is installed in the aircraft 1, including:

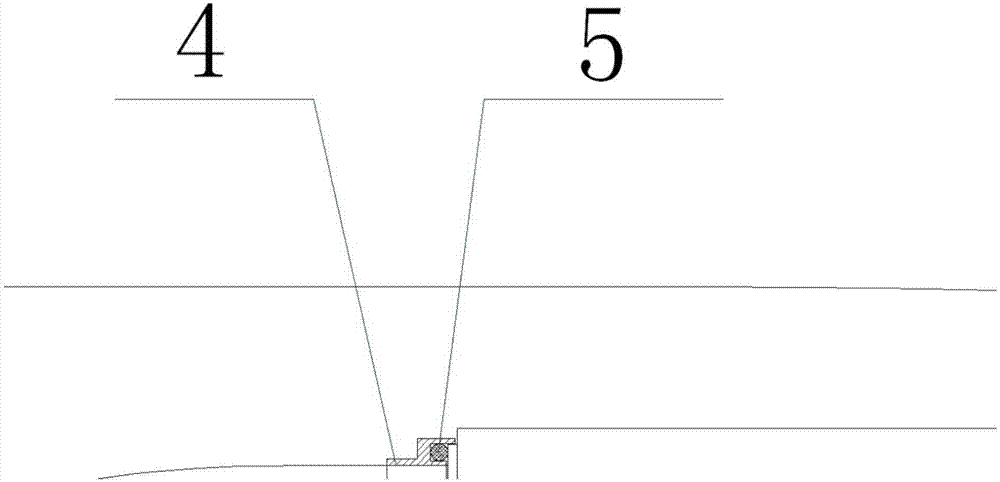

[0015] The engine 6 and the embedded air intake 3, the engine 6 is connected with the embedded air intake 3 through the flange 4, the rubber sealing ring 5 in the groove of the flange 4, the Embedded air inlet 3 inlets are provided with front blocking cover 2, and engine 6 spout places are provided with rear blocking cover 8; Described engine 6 inside is equipped with starter motor 7, after aircraft 1 assembly is finished, to engine 6 and buried Vacuumize the interior of the in-type air inlet 3;

[0016] When the engine 6 is ready to ignite and start, under vacuum conditions, use the starter motor 7 to directly bring the engine 6 speed to more than 90% speed; then open the front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com