Centrifugal radial flow turbine

A turbine and runoff technology, which is applied to the supporting elements of blades, stators, engine elements, etc., can solve the problems that affect the reliability and stability of equipment, the supply situation is controlled by others, and the price is high, so as to achieve the benefits of reliability and stability. , The effect of reducing equipment cost and increasing output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

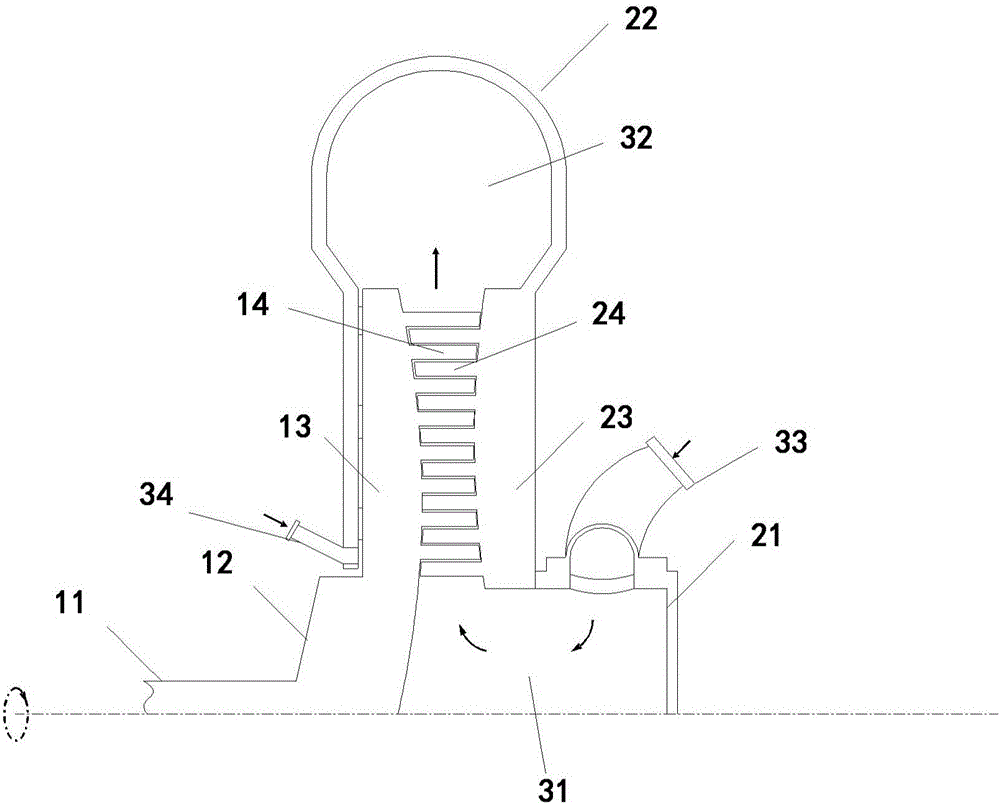

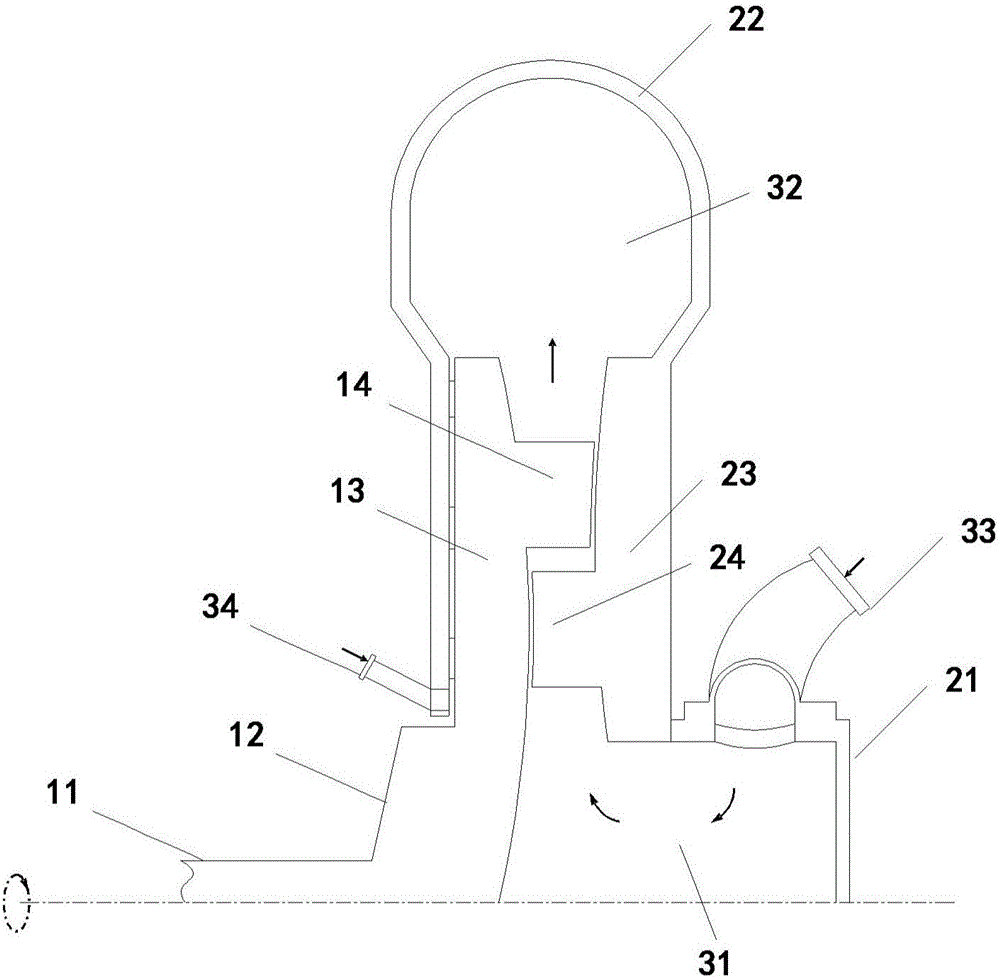

[0030] The invention discloses a centrifugal radial flow turbine, which is different from existing axial flow turbines and centripetal radial turbines. It has a large expansion ratio and high efficiency; at the same time, drawing on the adjustable guide vane technology, it can easily adjust the turbine flow rate, expand the operating range of the turbine, and finally ensure the achievability and economy of the thermal system.

[0031] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

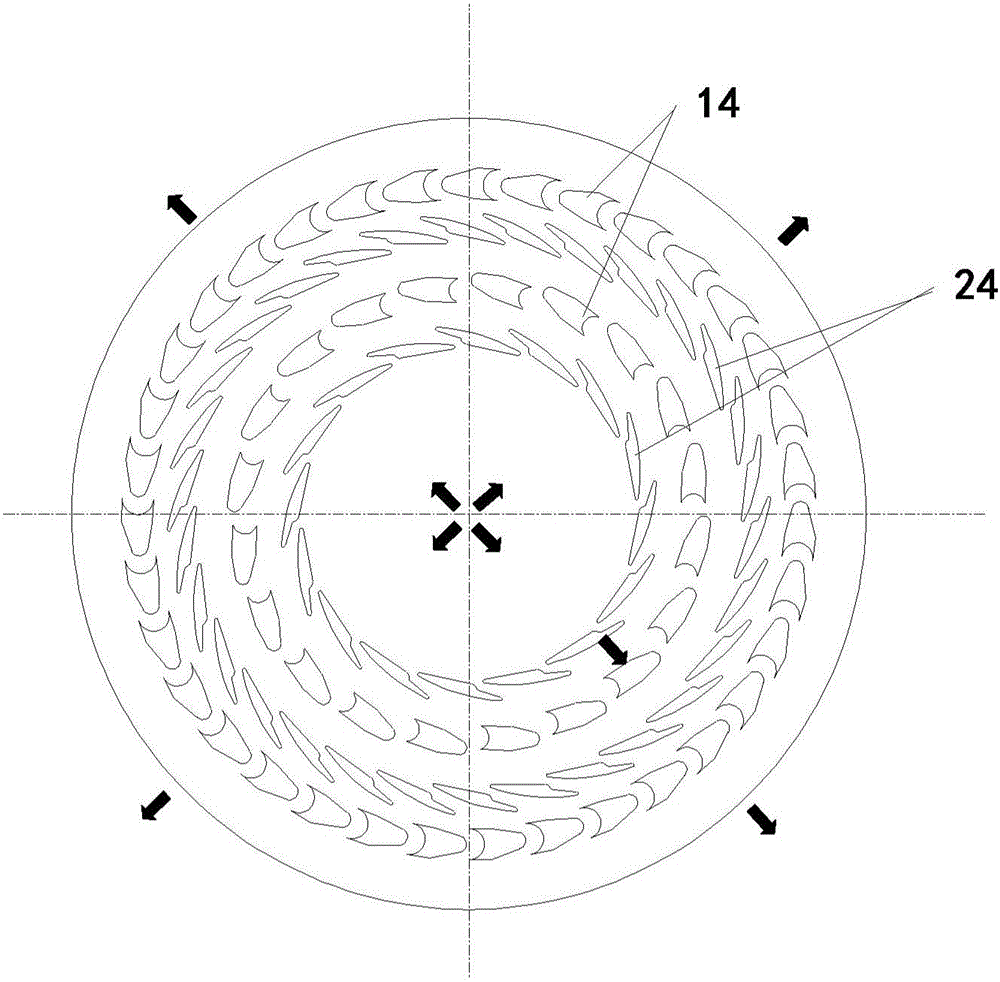

[0032] The centrifugal radial flow turbine of the embodiment of the present invention includes two parts, the rotor and the casing, wherein,

[0033] The rotor includes a rotating shaft 11, an impeller 12, a wheel disc 13 and moving blades 14. The rotor is centered on the rotating shaft 11, and alo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com