Motor clutch handle

A handle and clutch block technology, applied in the field of door handles, can solve the problems of poor safety, damage, high price, etc., and achieve the effect of preventing malicious damage and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

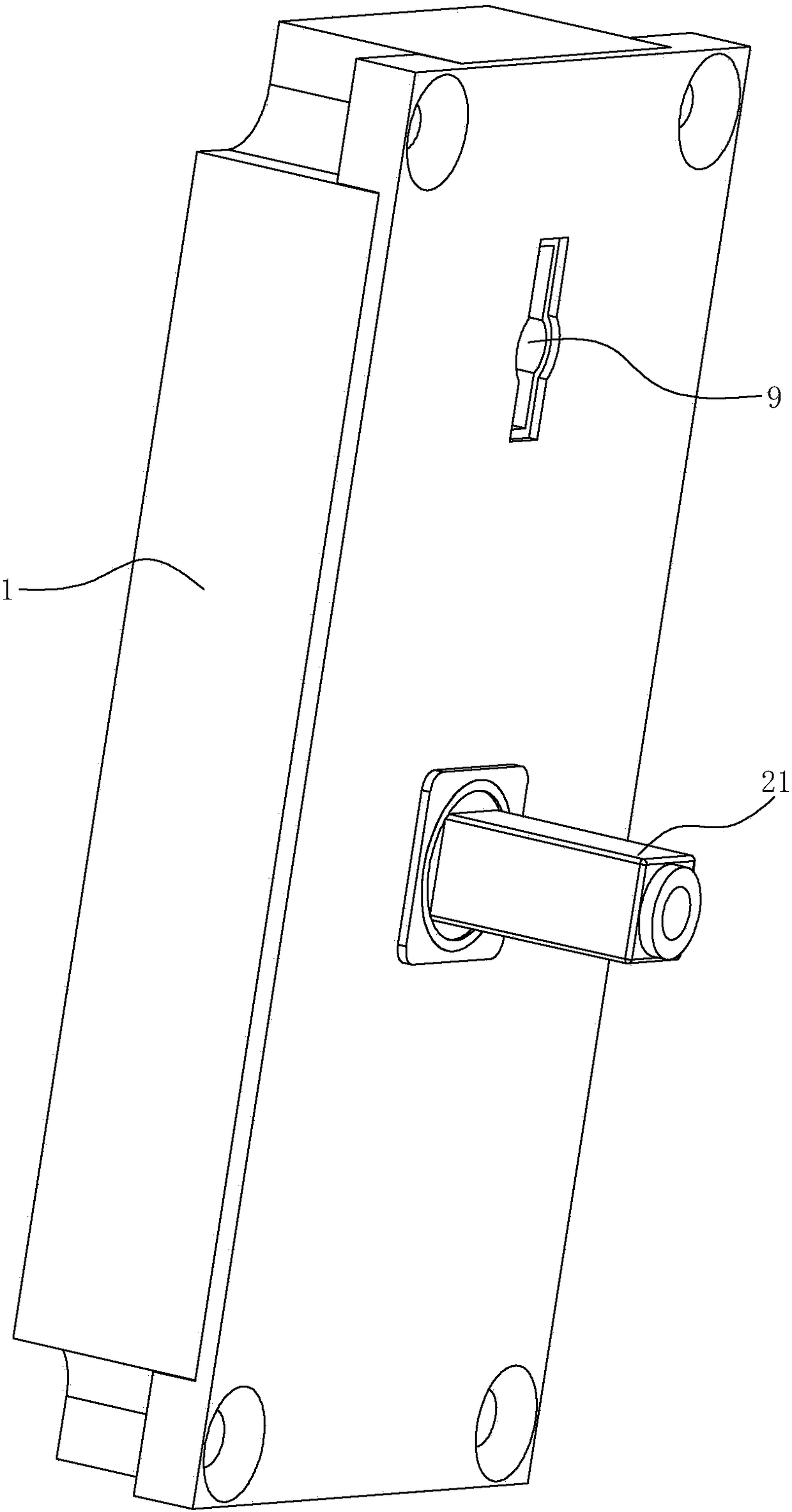

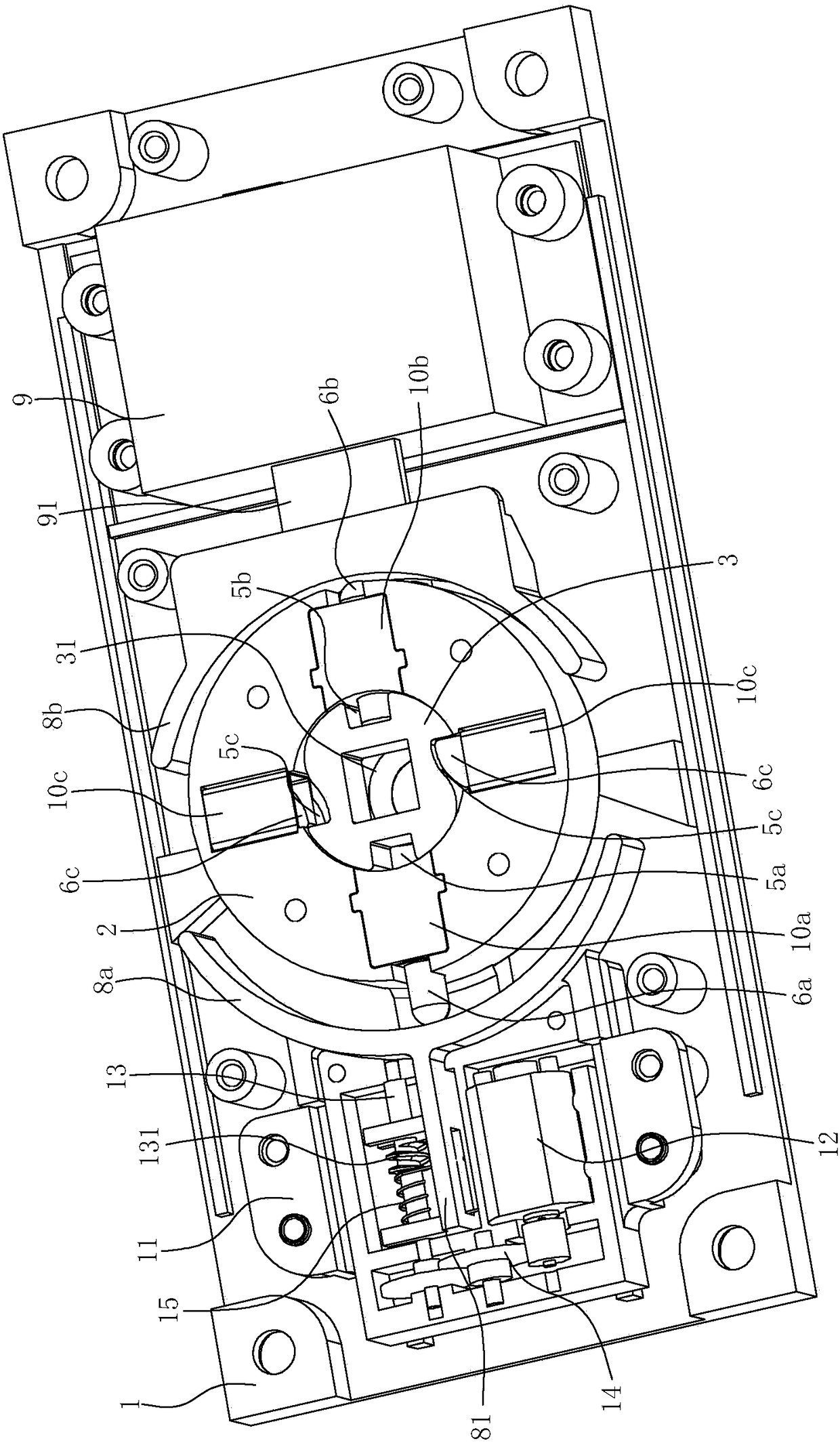

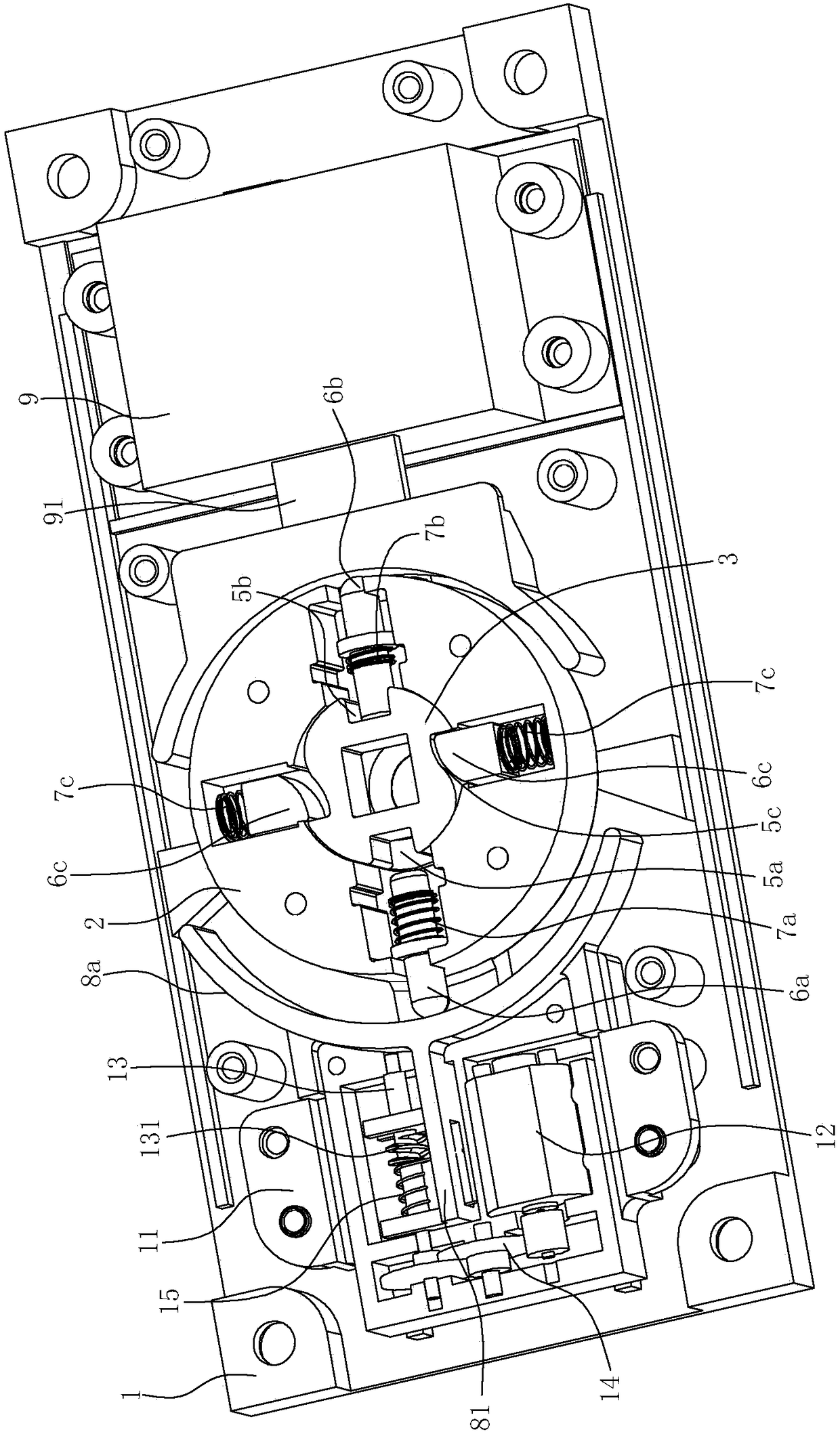

[0027] Such as Figure 1-8 Shown is a preferred embodiment of the present invention.

[0028] A motor clutch handle, including

[0029] The shell 1 is composed of a bottom plate and a cover.

[0030] The rotor 2 is installed in the housing 1 for rotation. The rotor 2 has a square shaft 21 for connecting with the outer handle. The square shaft 21 passes through the housing 1 to be connected with the outer handle.

[0031] The torsion spring 4 is arranged in the casing 1 and acts on the rotor 2 to reset the rotor 2 .

[0032] The clutch block 3 is arranged in the concave cavity in the rotor 2 and can rotate relative to the rotor 2. The center of the clutch block 3 has a square hole 31, and the outer periphery of the clutch block 3 has a concave first clutch notch 5a. The rotor 2 is bounded by The first drive pin 6a that can move radially, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com