Crucible facilitating polycrystal semi-melting process efficiency enhancing

A crucible and process technology, which is applied in the application field of polycrystalline ingot semi-melting process, can solve the problems of the introduction of carbon content or other impurities in the furnace cavity, increase labor force, etc., achieve centralized efficiency distribution, reduce inefficiency ratio, and ingot energy consumption reduced effect

Inactive Publication Date: 2016-11-09

常熟华融太阳能新型材料有限公司

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Various methods have been adopted in the industry, such as adding graphite soft felt and graphite hard felt to the edge of the guard plate, or adding graphite soft felt between the guard plate and the crucible, and adding porous graphite materials to the edge of the DS block and the bottom of the heat insulation cage to a certain extent. It can prevent the edge seed crystal from being melted, but it will easily lead to the introduction of carbon content or other impurities in the furnace cavity, and also increase the labor force of production. How to improve this situation, it will be of great significance to design a crucible with special specifications

Method used

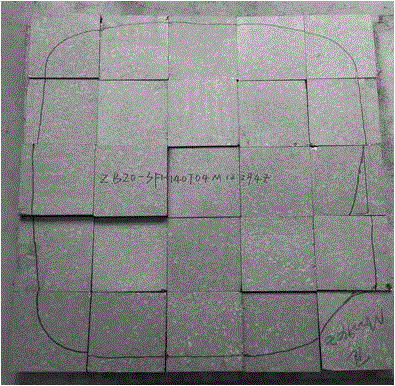

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0024] The thickness of the arc angle at the bottom of the crucible is set to 30 mm, the thickness of the hollowed out part of the crucible bottom is set to 18 mm, and the thickness of other parts is set to 25 mm, the ingot casting cycle is shortened by 3 hours, and 90% of the edge seed crystals are retained. The lines are consistent; the corresponding crucible parameters of each embodiment are shown in the table below.

[0025]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to a crucible facilitating polycrystal semi-melting process efficiency enhancing. Particularly, the thickness of the position of the arc angle at the bottom of the crucible is increased to 25-60 mm, the thickness of the hollowed-out position in the middle of the bottom of the crucible is reduced to 5-25 mm, the thicknesses of the other positions range from 20 mm to 60 mm, and the hollowed-out position in the middle of the bottom of the crucible is filled with processed graphite parts or other heat conducting materials. According to the crucible with the appearance, on the one hand, heat radiation of a heater at a melting stage to edge seed crystals is reduced, all the crystals are nucleated along bottom seed crystals to achieve the purpose of complete homogeneous nucleation, the low-efficiency proportion of edge crystal bars is reduced, the crystal ingot finishing efficiency can be improved by 0.05% to 0.2%, and efficiency is distributed in a more centralized mode; on the other hand, the thickness of the bottom is reduced so that DS blocks can be cooled more fully, nucleation is accelerated properly, the ingot casting time can be shortened by 2-4 hours, and the ingot casting energy consumption is reduced by 10-25%.

Description

technical field [0001] The invention relates to a crucible with a special shape, in particular to a polycrystalline ingot semi-melting process. Background technique [0002] With the improvement and innovation of the process technology, the polycrystalline ingot casting process currently has two major processes, the full melting process and the semi-melting process. Compared with the semi-melting process, the full melting process has a cost advantage and the efficiency is also increasing, but the average conversion efficiency Compared with the semi-melting process, there is still a slight gap, so the semi-melting process is still the majority in the industry. The semi-melting process generally uses a certain weight of crushed silicon or other small-sized silicon materials on the bottom of the polycrystalline crucible to achieve the purpose of homogeneous nucleation. The advantage is that the efficiency is slightly higher than that of the full melting. All, when the temperat...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C30B28/06C30B29/06

CPCC30B28/06C30B29/06

Inventor 张福军汪兴华

Owner 常熟华融太阳能新型材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com