Step-like belt conveyor

A belt conveyor and stepped technology, which is applied in the field of stepped belt conveyors, can solve the problem that the belt conveyor cannot transport materials and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

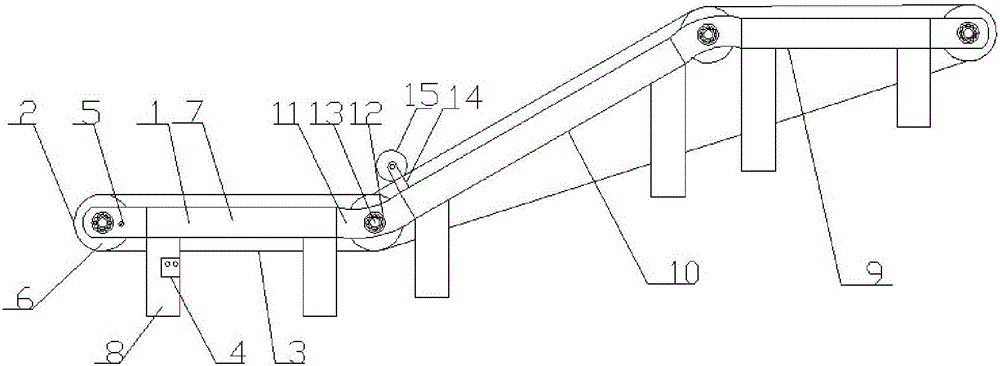

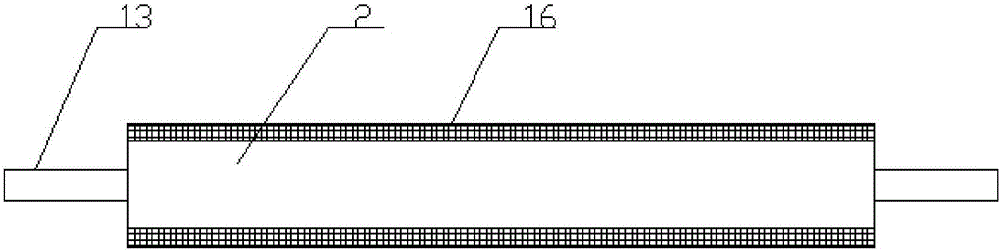

[0012] refer to figure 1 and figure 2 , a stepped belt conveyor, comprising a bracket 1, a conveyor roller 2 and a belt 3, the conveyor roller 2 is arranged on the bracket 1, and the bracket 1 is provided with a speed reducer 4 and a speed sensor 5, and the speed sensor 5 is opposite to the shaft end 6 of the conveying roller, the belt 3 is laid on the conveying roller 2, the support 1 includes a flat plate 7 and a foot 8, the flat plate 7 includes a horizontal section 9 and an inclined section 10, and the horizontal section 9 and The inclined section 10 is provided with a gap, the two ends of the gap are connected by a connecting shaft seat 11, the horizontal center of the connecting shaft seat 11 is kept at the same height as the horizontal center of the flat plate 7, and the connecting shaft seat 11 is sleeved with a bearing 12 , the two ends of the conveying roller 2 are provided with a connecting shaft 13, the connecting shaft 13 is sleeved in the bearing 12, the head e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com