Supporting device for tyre assembly

A support device and tire assembly technology, applied in tire installation, tire parts, wheel assembly and disassembly equipment, etc., can solve the problems of inconvenience, labor and time, etc., and achieve convenient lifting and lowering, good versatility, and tire replacement process Time-saving and labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

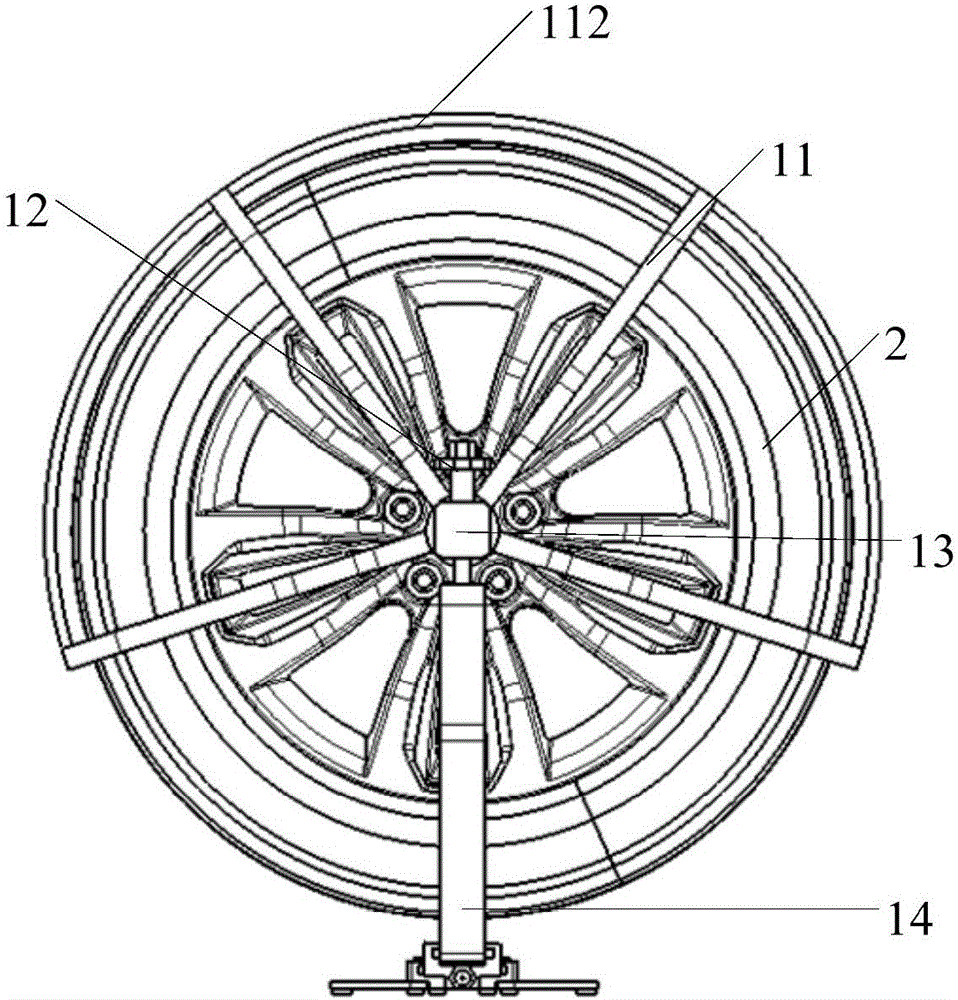

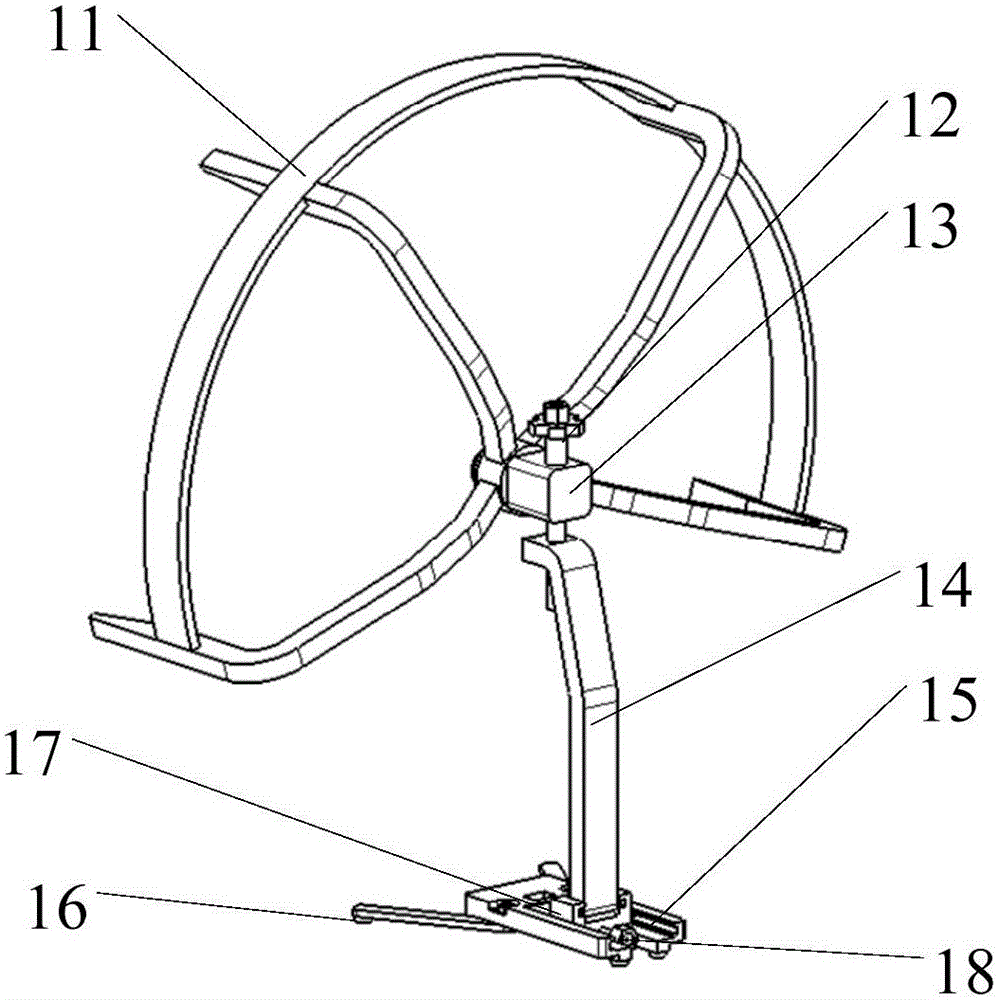

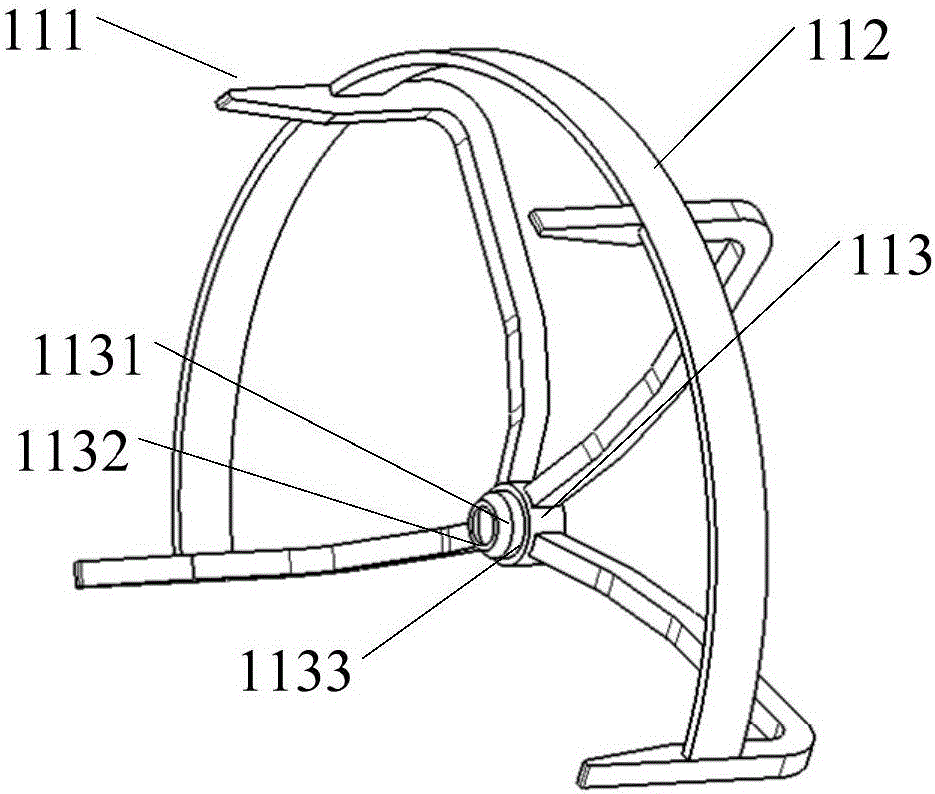

[0045] like Figure 1 to Figure 11 As shown, the embodiment of the present invention provides a tire assembly support device, including a support base 11, a connecting portion and a base portion.

[0046] Wherein, the support base 11 includes a support shaft 113, a reinforcement ring 112 and a claw bracket 111, and the reinforcement ring 112 and the support shaft 113 are connected through the claw bracket 111; the connection part includes an adjustment bolt 12, a rotating connection shaft 13 and a support arm 14, The rotating connecting shaft 13 cooperates with the supporting shaft 113, the rotating connecting shaft 13 can move and rotate axially along the supporting shaft 113, and the adjusting bolt 12 connects the rotating connecting shaft 13 and the first end of the supporting arm 14; the base part includes a base 15, a slide Move the base 17 and the lead screw 18, the second end of the support arm 14 is fixedly connected with the sliding base 17, the sliding base 17 is sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com