A two-roll continuous casting slab corner rolling device with inclined rolls

A technology of continuous casting slab and roll, which is applied in the field of two-roll continuous casting slab corner rolling device, which can solve the problems of high rolling pressure and reduced roll life, and achieve the effect of small rolling resistance and simple equipment maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with embodiments.

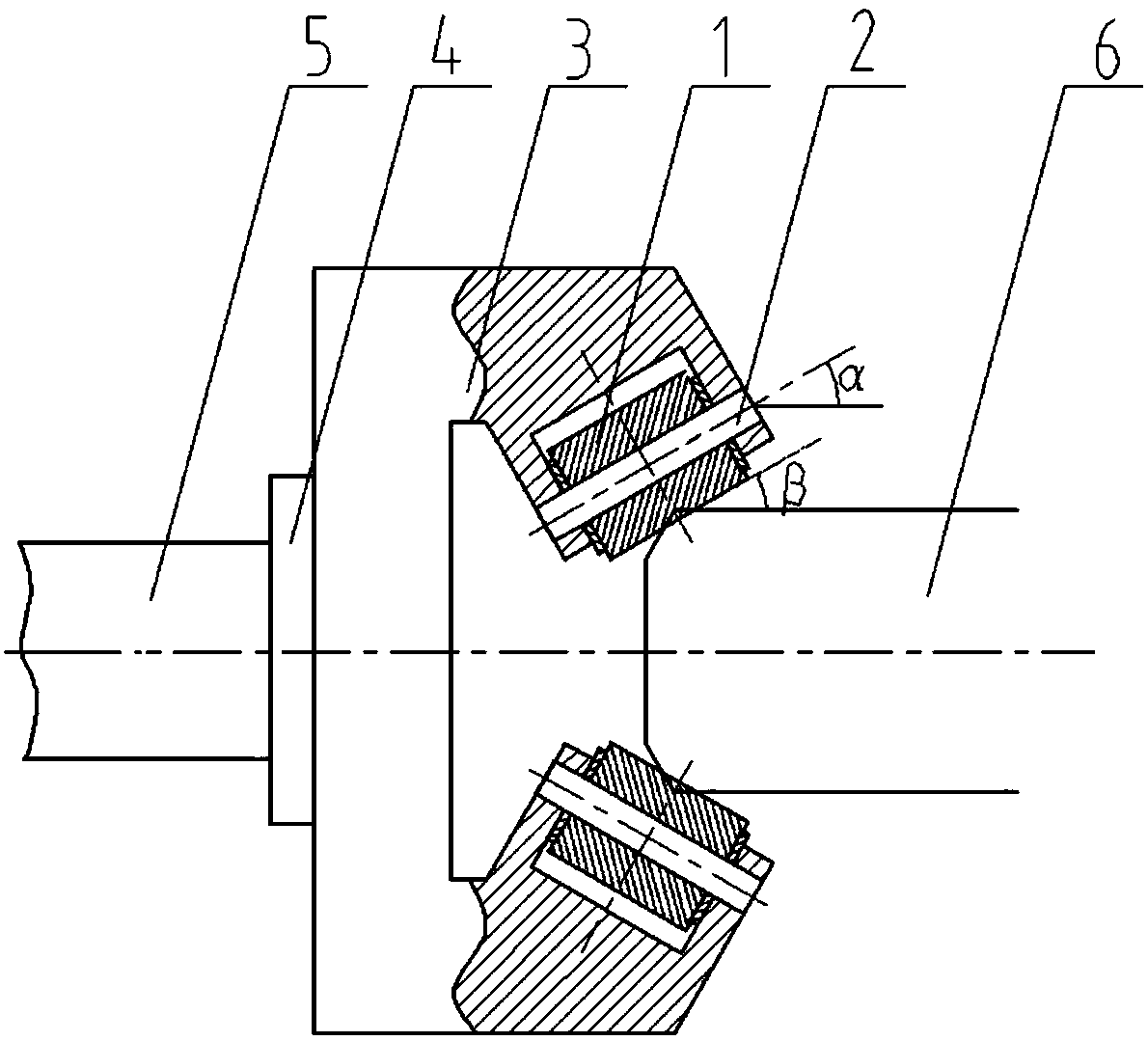

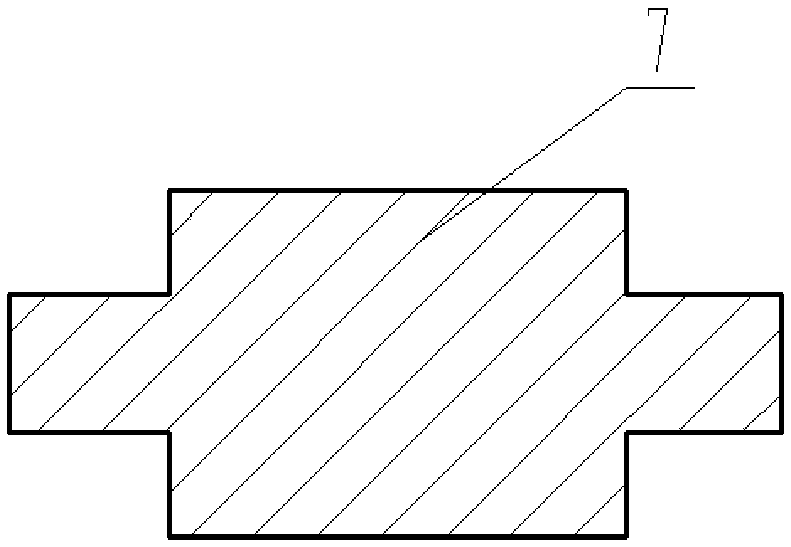

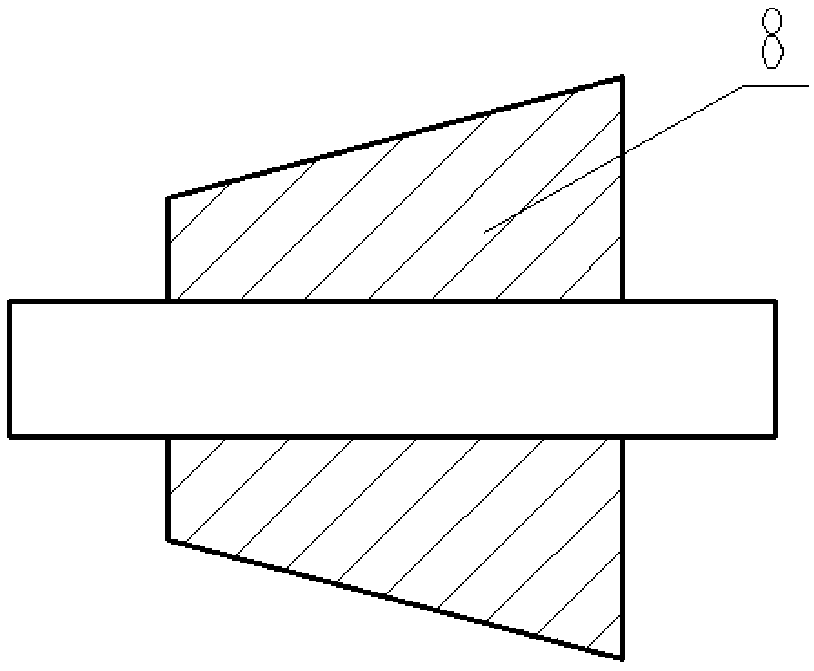

[0043] A two-roll continuous casting billet cornering device with inclined rollers of the present invention includes a chamfering roller 1, a roller shaft 2, a roller support frame 3, a connecting piece 4 and a driving push rod 5. The roll support frame 3 is connected to a drive push rod 5 that can move forward and backward. The two cantilever ends of the roll support frame 3 are respectively provided with a chamfering roll 1; the two chamfering rolls 1 are arranged symmetrically, and the chamfering roll 1 The roll surface is at an oblique angle with the wide surface of the cast slab;

[0044] The device is installed on the left and right sides of the continuous casting slab 6 to continuously roll the corners of the continuous casting slab 6.

[0045] The two chamfered rolls 1 on the two cantilever ends of the roll support frame 3 can be arranged symmetrically or asymmetrically.

[0046] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com