EGR valve assembly

An EGR valve and component technology, applied in engine components, exhaust gas recirculation, machine/engine, etc., can solve problems such as damage to turbocharger compressors, interference, deterioration of internal combustion engine performance, etc., to achieve a simple structure and reduce interference. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

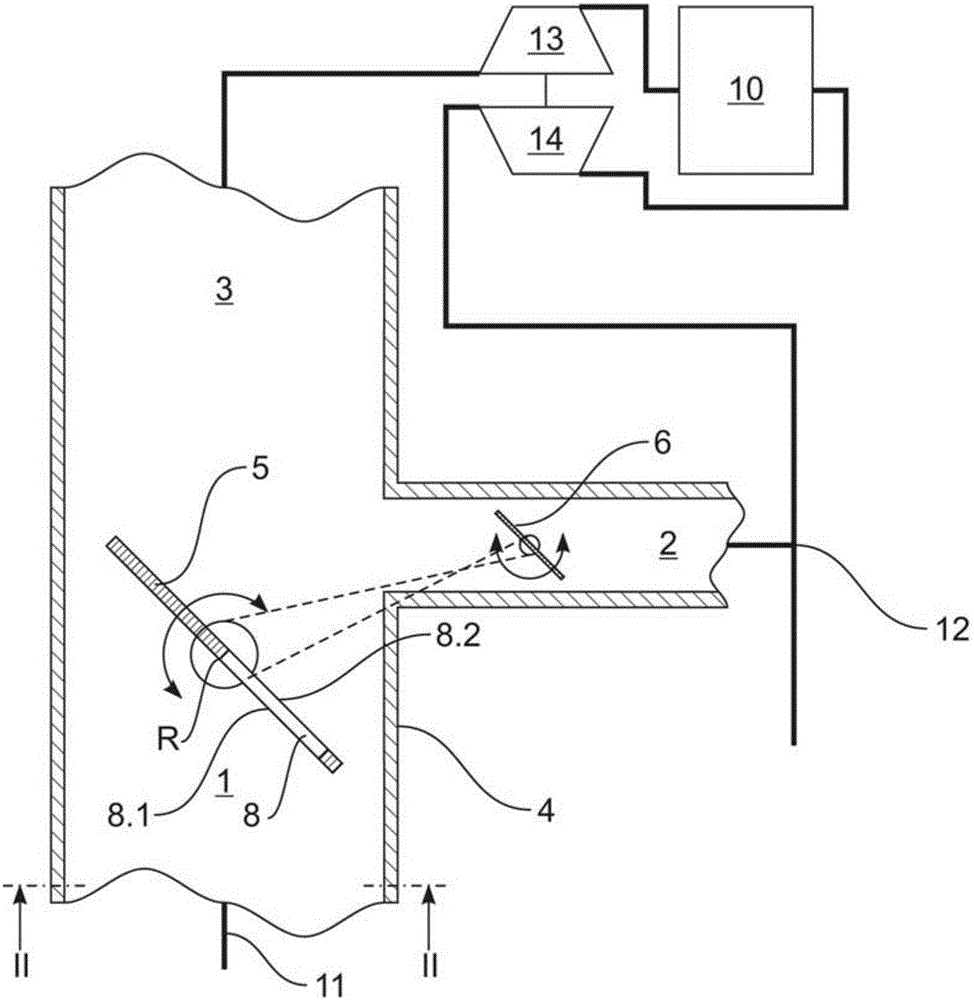

[0031] figure 1 Partially schematically shown is an internal combustion engine of a passenger car having an EGR valve assembly according to an embodiment of the present invention.

[0032] The internal combustion engine comprises a cylinder device 10, an air intake pipe 11 for supplying air to the cylinder device 10, an exhaust pipe 12 for discharging exhaust gas from the cylinder device 10, a turbocharger and an LP-EGR system, the turbo A supercharger includes a compressor 13 that compresses intake air and a turbine 14 that drives and drives the compressor 13 through exhaust gas, and the LP-EGR system includes the (LP-)EGR valve assembly.

[0033] The LP-EGR valve assembly includes an intake air passage 1 , an exhaust passage 2 and an outlet passage 3 formed in or through a common housing 4 .

[0034] The intake passage 1 communicates with the air intake pipe 11 , the exhaust passage 2 communicates with the exhaust pipe 12 downstream of the turbine 14 , and the outlet passage ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap