Improved beverage and method of preparation

A beverage and aerated beverage technology, applied in dairy products, milk preparations, food science, etc., can solve the problems of inconsistency, undesired stability of beverages, and inability to prepare beverages, etc., to achieve low fat content, good sensory characteristics and bubble retention sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0160] Example 1: Exemplary reconstituted milk comprising UF milk-based retentate

[0161] components Amount (weight%) Milkfat (FFMR) 1.5 skim milk 73.875 (provides 51% total protein) Heat-treated UF retentate 24.625 (provides 49% total protein) water Make up to the specified volume (To volume)

[0162] Note: Total protein equals 5.7 wt%, provided by both SMP and UF retentate. Total solids (TS) equals 12.6% by weight.

Embodiment 2

[0163] Example 2: Preparation method of reconstituted milk containing retentate

[0164] 1. Mix milkfat heated to 50°C (FFMR) with a mixture of skim milk heated to 50°C and heat-treated UF retentate.

[0165] 2. Pre-homogenize the mixture in a high shear mixer (eg Silverson) at 10000 rpm for 2 minutes.

[0166] 3. Heat the pre-homogenized mixture to 65-70° C. and then homogenize in a 2-stage homogenizer at 200 / 500 bar.

[0167] 4. The homogenized mixture was then pasteurized at 74°C for 15 seconds and filled into bottles. Alternatively, the homogenized mixture can be UHT treated at 142°C for 4 seconds. The same functionality was observed with either treatment in this step.

[0168] 5. The reconstituted milk can then be stored or used immediately prior to ingestion for aeration purposes.

[0169]

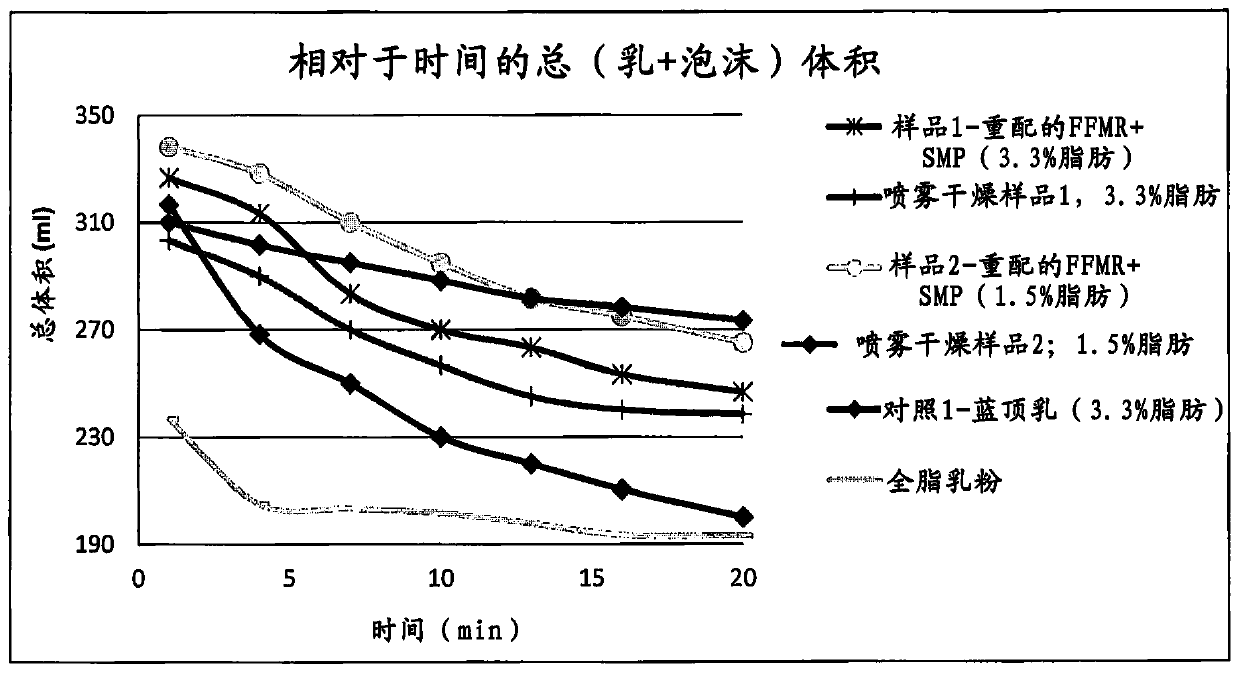

[0170] It will be appreciated that the mixture (reconstituted milk with retentate) may be spray dried, for example, for forming a dairy product. For example, the drying metho...

Embodiment 3

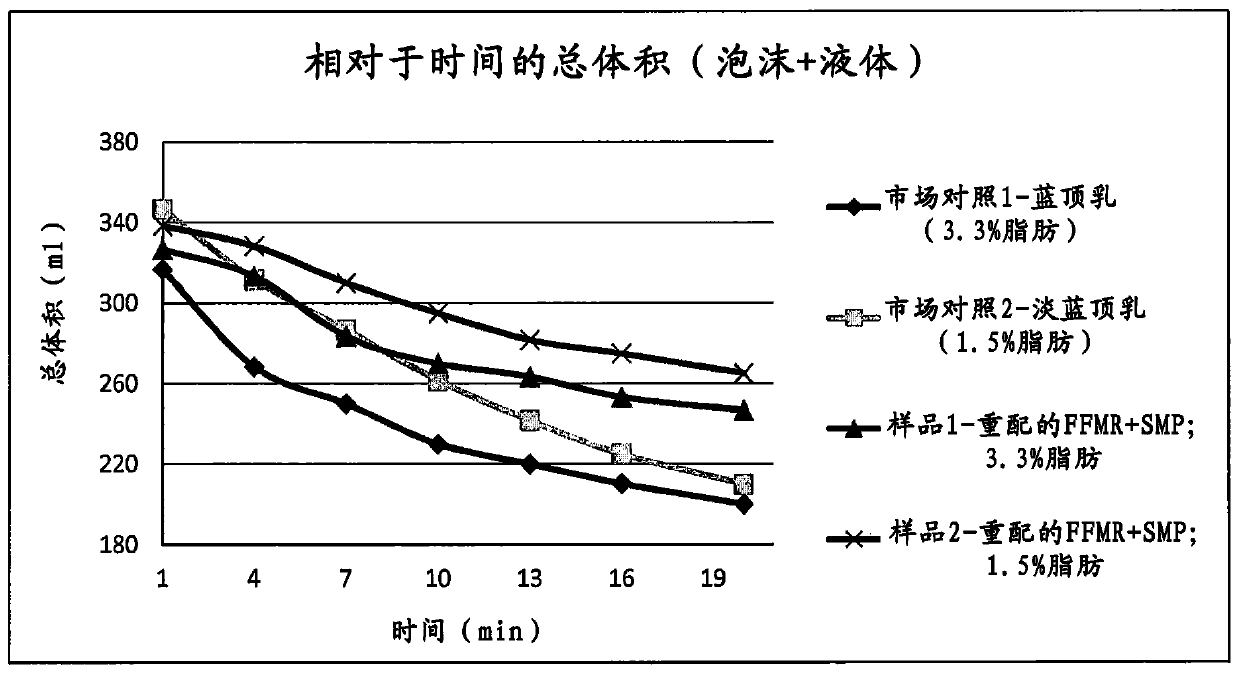

[0171] Example 3: Method of aerating a beverage comprising reconstituted milk

[0172] 1. Prior to ingestion, reconstitute the reconstituted milk components into solution if they have not already been reconstituted into solution.

[0173] 2. Aeration of the cold drink containing reconstituted milk is done by hand mixing or mechanical mixing at a speed of 1000-15000 rpm for about 10-120 seconds to whip the drink.

[0174] 3. In another use, ready-to-drink (RTD) beverages can be prepared from reconstituted milk compositions, in bottles or cartons after pasteurization / UHT / hot-fill / tunnel pasteurization in packaging. It is preferable to provide some headspace in the packaging.

[0175] Shaking the bottle / carton will create foam / bubbles in the beverage which will in turn enhance the organoleptic profile.

[0176] It should be understood that while preliminary trials were conducted with cold beverages, it is expected that the invention will be more commonly applied to hot beverag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com