Drill hoisting speed and direction control assembly for core-drilling machine

A technology of drilling cores and increasing speed, which is applied in the direction of sampling devices, etc., and can solve problems affecting the operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

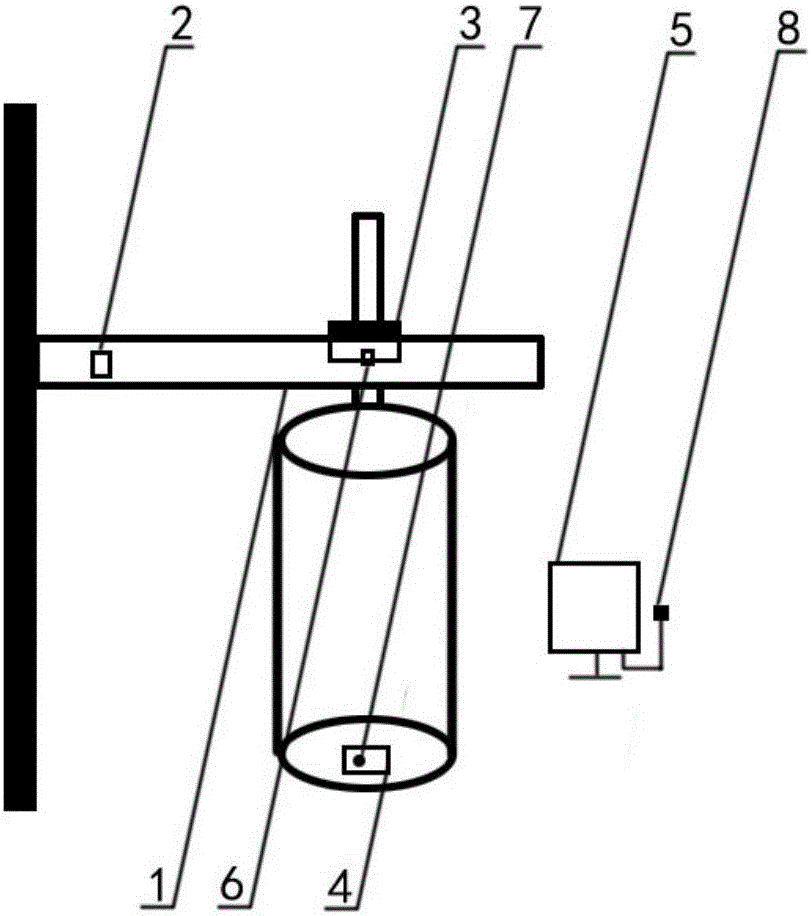

[0012] Embodiment: as shown in the accompanying drawing. The drill bit lifting speed and orientation control assembly of the drilling coring machine includes a body (1), on which an operation sensing module (2), a lifting control module (3), a pressure sensing module (4), and a management module ( 5), during operation, the operation sensing module (2) senses the operating state of the fuselage, the lifting control module (3) controls the lifting of the drill bit, the pressure sensing module (4) senses the force on the drill bit, and the management module (5) handles the comprehensive information.

[0013] The drill bit lifting speed and orientation control assembly of the drilling coring machine is provided with a speed control module (6) on the lifting control module (3) to control the lifting speed of the drill bit according to the operating state of the fuselage.

[0014] The drill bit of the drilling coring machine is lifted up to the speed and orientation control assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com