Spinning reel

A yarn bobbin and cylinder technology, applied in the field of textile yarn bobbin, can solve the problems that the bobbin has no anti-slip function, does not have reusability, and is easy to loosen, etc., and achieves the effect of light weight, simple structure, and easy transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

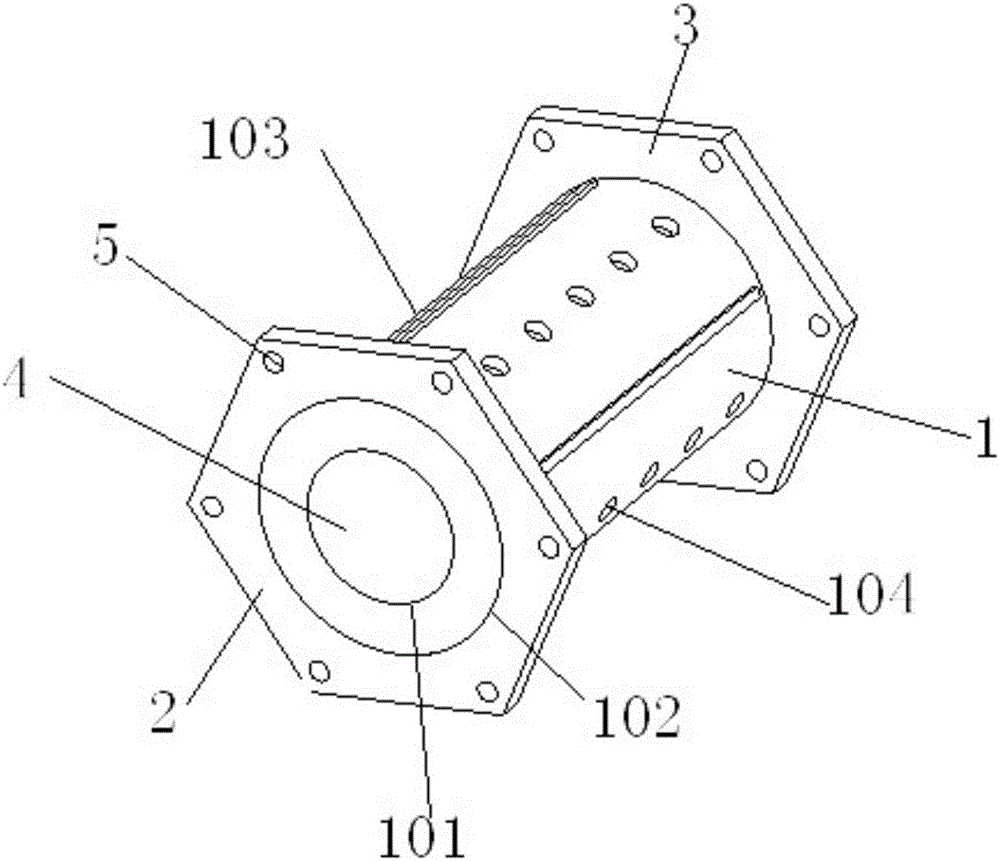

[0018] like figure 1 As shown, a kind of spinning bobbin of the present invention comprises a cylindrical hollow tube 1, a left disc 2 and a right disc 3, and the cylindrical hollow tube 1 includes a cylindrical inner tube 101 and a cylindrical outer tube 102, and the cylindrical outer tube 102 The outer surface is provided with anti-slip lines 103 and a plurality of drying holes 104, and a cavity is formed between the cylindrical inner tube 101 and the cylindrical outer tube 102, and a desiccant is provided in the cavity to prevent moisture, and the cavity structure greatly saves the amount of materials , thereby reducing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com