Compression roller assembly jig and compression roller assembly method in dry granulation device

A granulation device and assembly fixture technology, applied in the direction of mold extrusion granulation, etc., can solve the problems of time-consuming, compression roller injury, staff burden, etc., and achieve the effect of easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

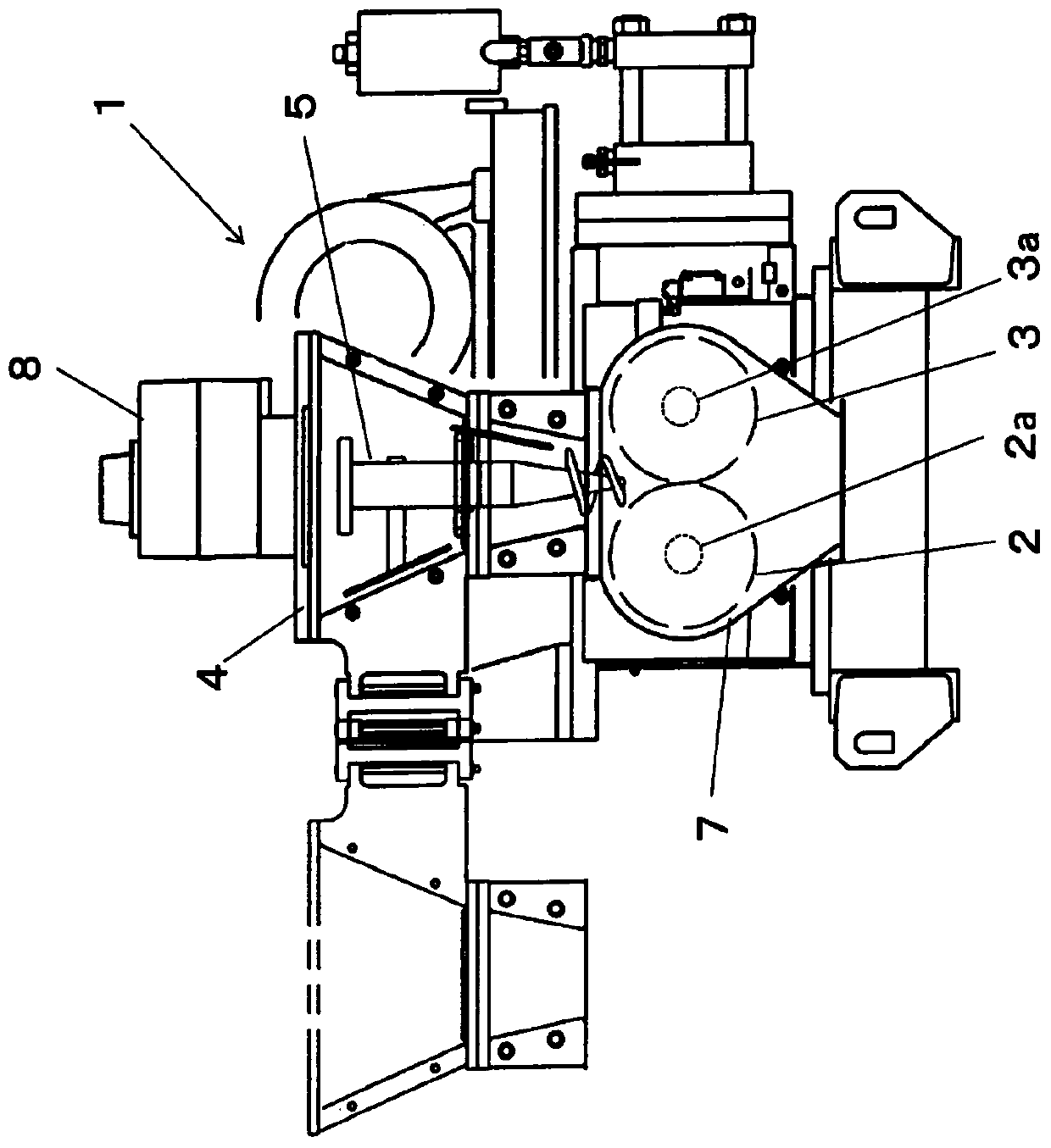

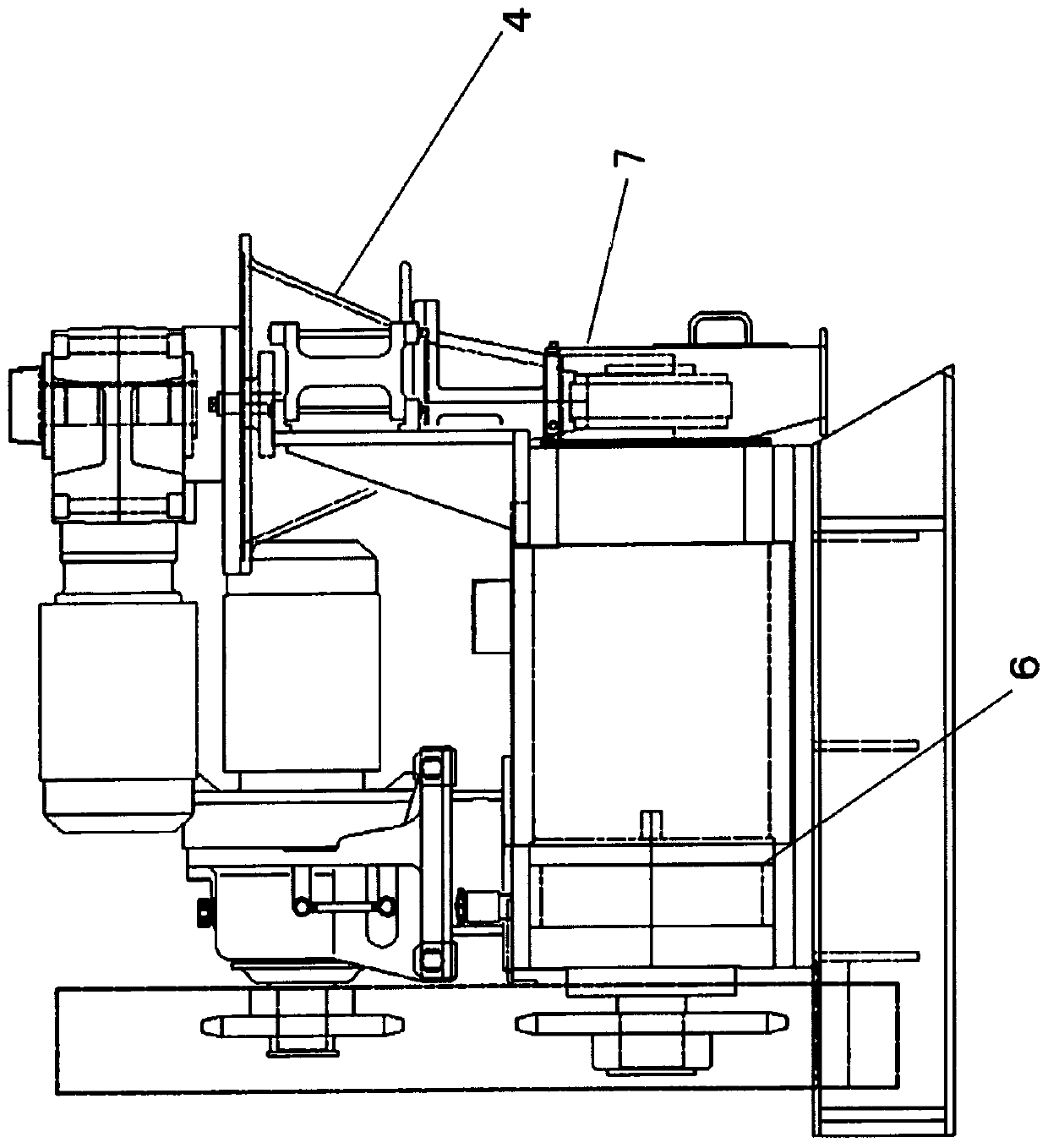

[0020] Hereinafter, embodiments of the present invention will be described in detail based on the drawings. figure 1 It is a front view showing an example of a dry granulation apparatus to which an assembly jig and an assembly method of a compression roll according to an embodiment of the present invention are applied, figure 2 yes figure 1 Side view of the dry granulation apparatus shown.

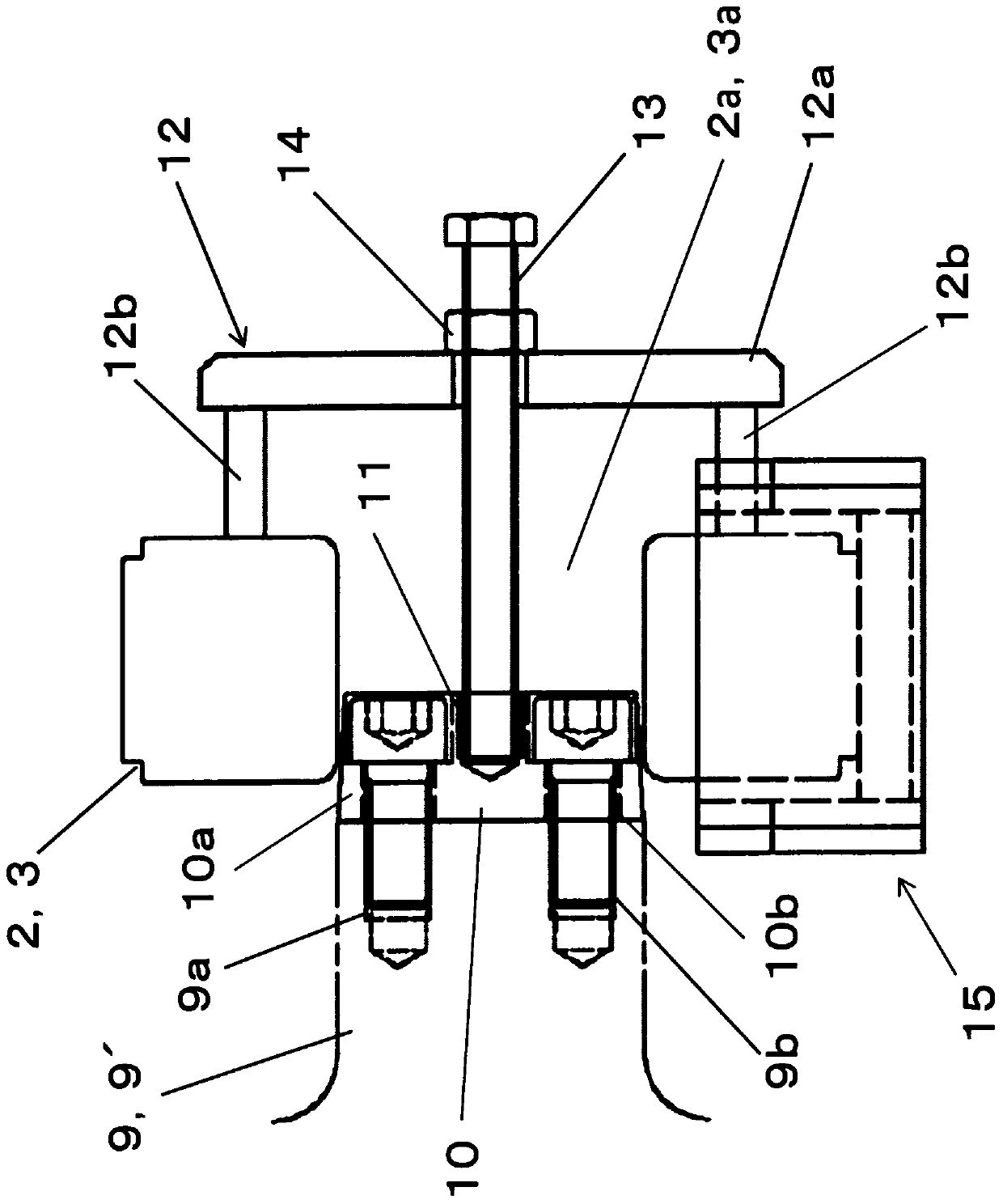

[0021] in addition, image 3 It is a figure which shows the intermediate state which assembles a compression roller to a rotating shaft using the assembly jig of this invention. and, Figure 4 is viewed from the right side image 3 , the dotted lines represent hidden lines.

[0022] figure 1 , figure 2 The shown dry granulation device 1 includes a pair of compression rolls 2 and 3 . A hopper 4 for storing powder for granulation is provided above the compression rollers 2 and 3 . The powder is supplied between the compression rollers 2 and 3 by the feed screw 5 provided in the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com