A collarless round neck sewing process of elastic fabric

A technology of elastic fabrics and craftsmanship, applied in the field of clothing sewing, can solve the problems of neckline turning, troubles, and not allowed to add topstitching, etc., to achieve the effect of increasing support and increasing hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

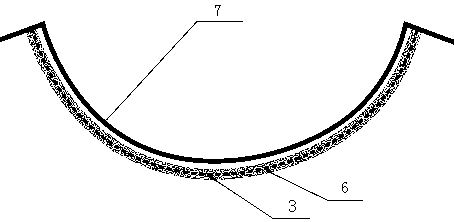

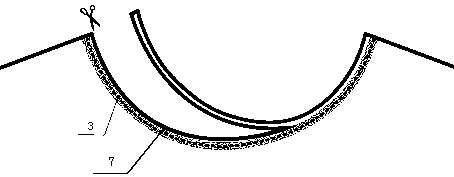

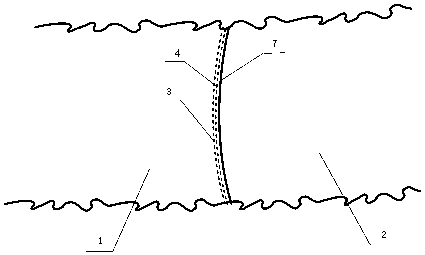

[0019] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. The present invention discloses a collarless round neck sewing process for elastic fabrics, comprising the following steps:

[0020] 1. Cut out the round neck piece of elastic fabric 2, and glue the 1CM wide straight silk lining strip 6 on the reverse side of the collar before sewing. The position of the straight silk lining strip 6 can make the straight silk lining when sewing The upper and lower centerlines of strip 6 coincide with the suture line 3 of the collar pocket; the adhesive seam straight thread lining strip 6 is because the neckline is cut with diagonal threads, so the size of the collar pocket is easy to become larger after sewing, and because the sewing worker's technique The uncertainty of the amount of force can easily cause the size of the collar pocket to be inconsistent. In order to prevent this from happening, the fabrics o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com