Press-bar-type seeder for potato planter

A seeder and pressure rod type technology, applied in the field of pressure rod type seeders of potato seeders, can solve the problems of inability to ensure that all potato sprouts face upward, troublesome potato planting process, affecting potato growth, etc. The effect of long life and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

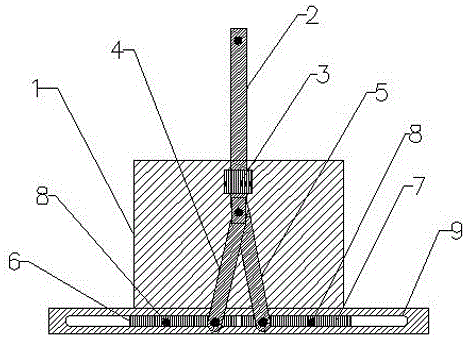

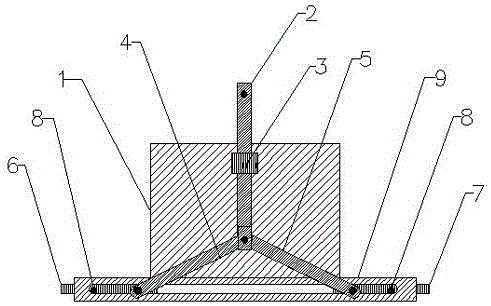

[0014] like Figure 1-2 As shown, a potato planter pressing rod type seeder includes a tray (1), a vertical pressing rod (2), a shaft sleeve (3), a left connecting rod (4), a right connecting rod (5), and a left sliding plate (6), right skateboard (7), guide shaft (8), skateboard frame (9), there are front and rear two skateboard frames (9) symmetrically welded on the front and rear sides of the lower end of the tray (1), and the tray box (1) Located in the middle of the front and rear skateboard racks (9), the left skateboard (6) and right skateboard (7) are symmetrically arranged between the front and rear two skateboard racks (9), and the vertical pressure rod (2) passes through the bushing (3) It is fixed on the front side of the tray (1), and the lower end of the vertical pressing rod (2) is hinged with the upper ends of the left connecting rod (4) and the right connecting rod (5) through pivot pins, and the left connecting rod (4), The lower end of the right connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com