An operating vehicle for overhauling large-span transmission lines

A transmission line and large-span technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of high psychological pressure, long time to go out of the line, low work efficiency, etc., and achieve the effect of improving stability, reducing shaking problems, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

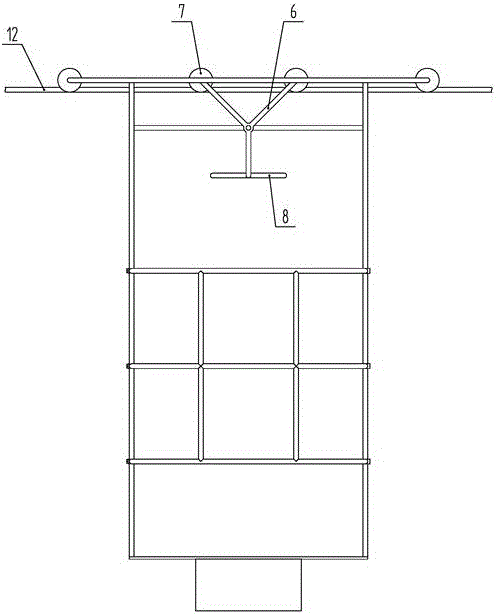

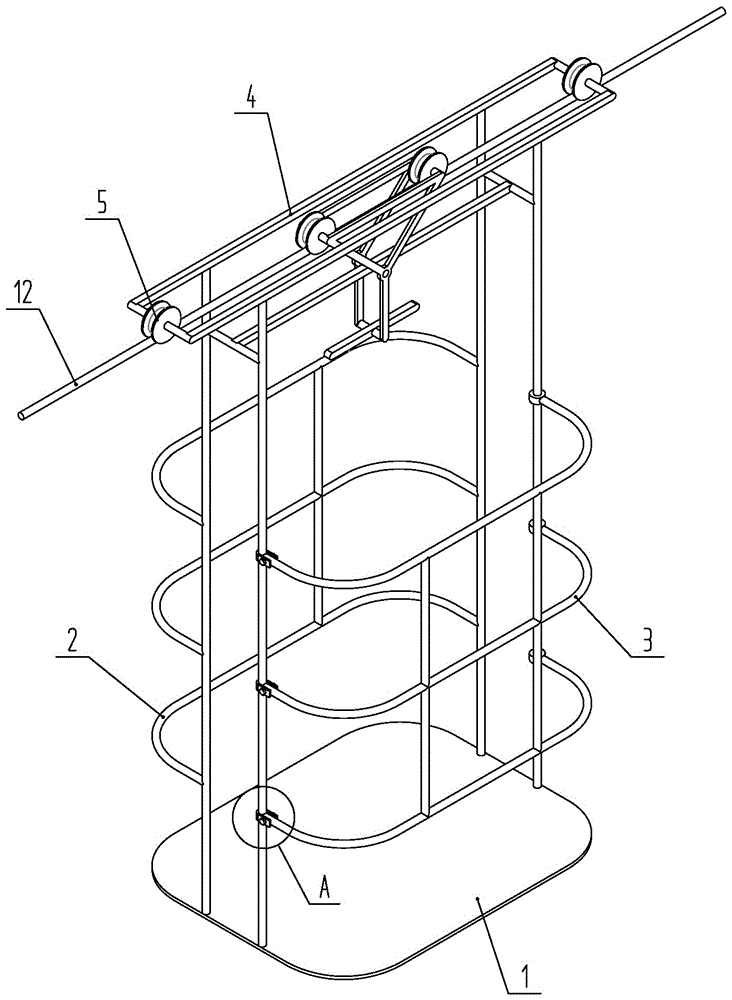

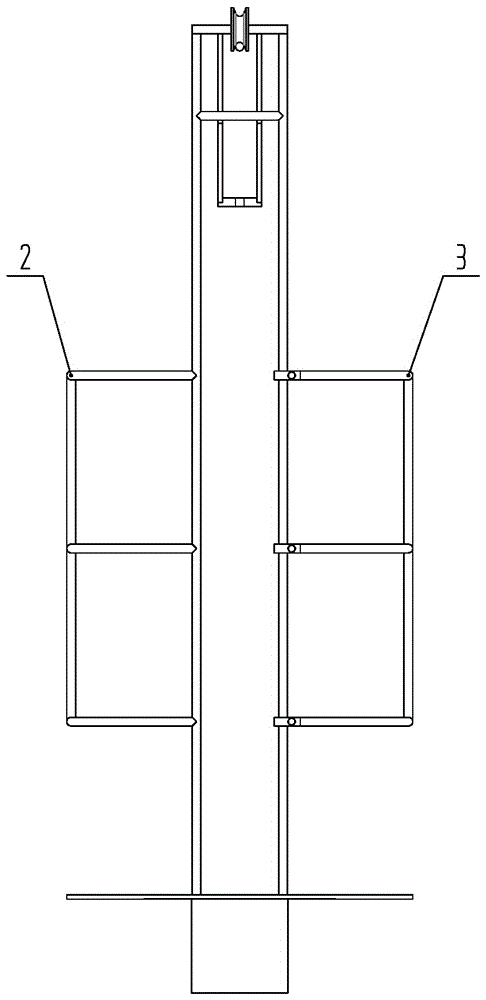

[0027] Such as Figures 1 to 5 As shown, a work vehicle for overhauling a large-span transmission line includes a work cage, a main wheel frame 4 horizontally installed on the top of the work cage, and a main pulley 5 movably installed on the main wheel frame 4 .

[0028] The work cage includes a base plate 1 for the operator to stand on, a cage fence 2 fixed on the base plate 1, and a cage door 3 rotatably installed on the cage fence 2; the cage door 3 can be opened around the rotation axis for the operator Going in and out, also can lock the cage door 3 and the cage frame fence 2 by the door lock mechanism on the movable end of the cage door 3 to ensure the safety of the operator. Cage frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com