Liquid crystal panel and liquid crystal display

A liquid crystal panel and liquid crystal cell technology, applied in optics, instruments, nonlinear optics, etc., can solve the problems of large light leakage, low contrast, and color shift in black display, and achieve the effects of uniform color tone, small color change, and small color shift.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

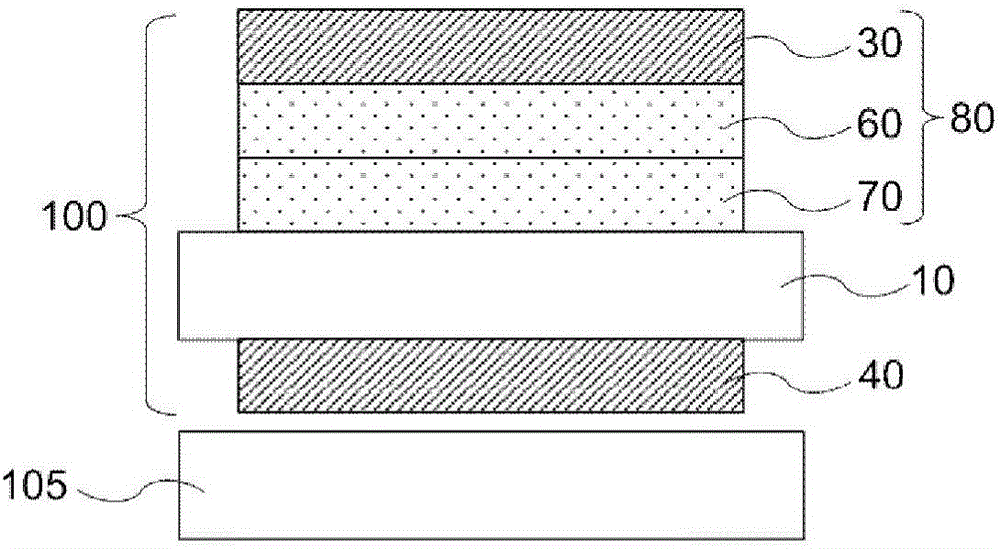

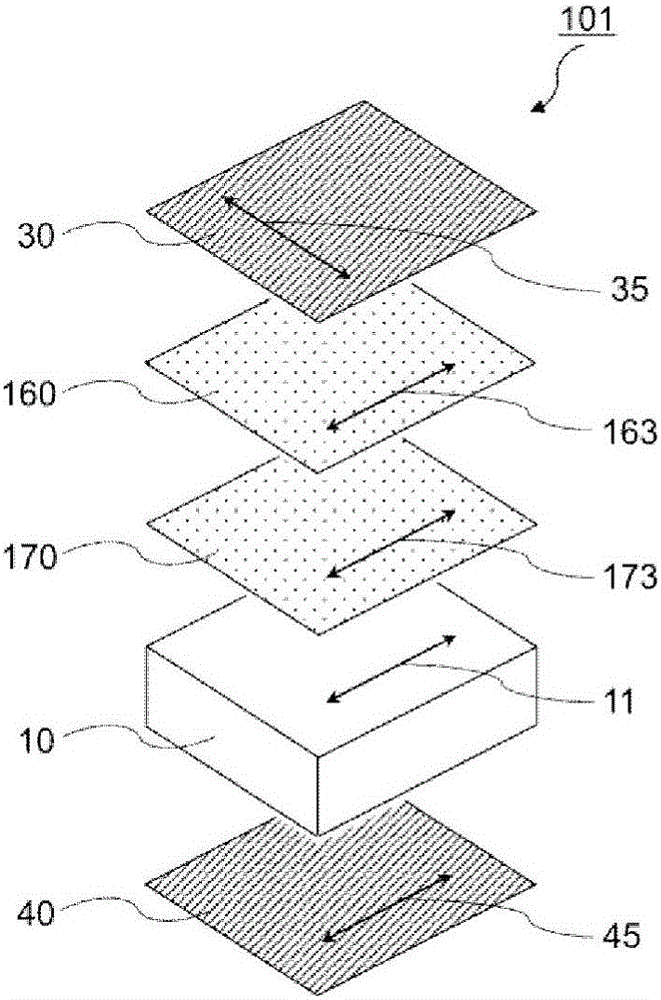

[0093] Polarizing plate, IPS liquid crystal cell (front retardation: 322nm, pretilt angle: 0.1°), second optical anisotropy element (negative A plate of nx=nz>ny; front retardation Re 2 =120nm), the first optical anisotropic element (negative C plate of nx=ny>nz; thickness direction retardation Rth 1 =80nm) and an O-mode liquid crystal display device of a polarizing plate were used as simulation models, and simulations were performed. Both the wavelength dispersion of the retardation of the first optical anisotropic element and the second optical anisotropic element were set to R450 / R550=1.10. The configuration of each optical anisotropic element is as follows Figure 4 shown.

[0094] For the simulation, a simulator for liquid crystal displays "LCD MASTER Ver. 6.084" manufactured by Shintech Co., Ltd. was used. Use the extended function of LCD Master to obtain the contrast in each viewing direction (polar angle θ=0-80°, azimuth angle φ=0-360°) and the chromaticity xy of th...

Embodiment 2~4 and comparative example 3

[0102] Same as in Example 1, using a liquid crystal cell with a pretilt angle of 0°, the thickness direction retardation Rth of the first optical anisotropic element 1 The simulation was carried out by changing to 60 nm and changing the wavelength dispersion R450 / R550 of the retardation of the first optical anisotropic element and the second optical anisotropic element. express the result in Figure 6 middle.

[0103] Depend on Figure 6 As a result, it can be seen that if the optical anisotropic elements have the same retardation value at a wavelength of 550 nm, there is no large change in contrast even if the wavelength dispersion is different. In Comparative Example 3 where both the first optical anisotropic element and the second optical anisotropic element are retarded and the wavelength dispersion R450 / R550=1.02, it can be seen that the area surrounded by the locus on the chromaticity diagram is large and the color shifts Big. In addition, in Comparative Example 3, i...

Embodiment 5~7 and comparative example 4

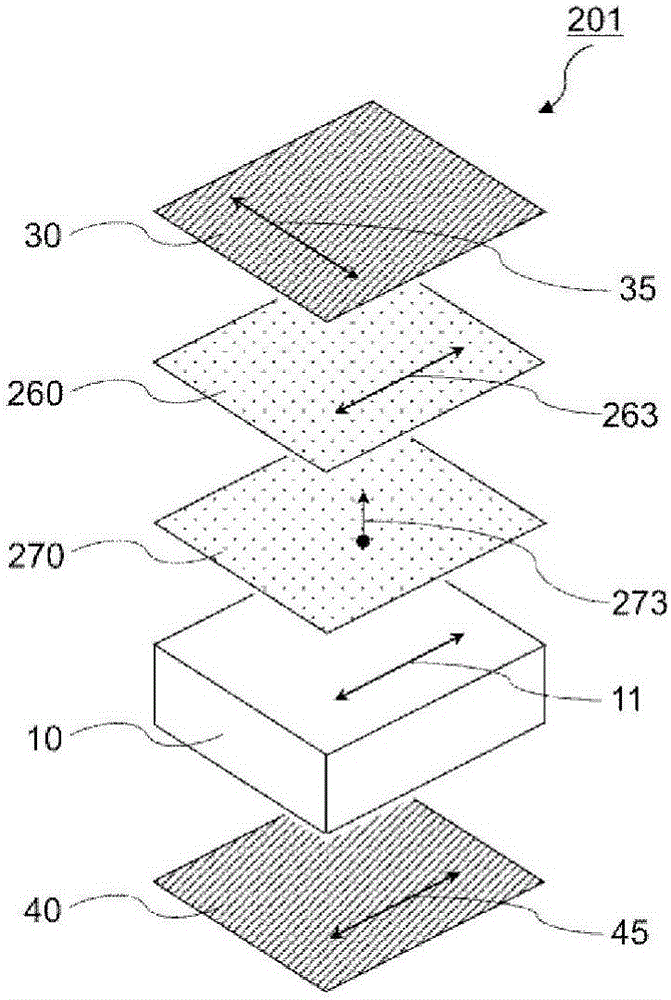

[0106] Use a liquid crystal cell with a pretilt angle of 0°, use a negative C plate with nx=ny>nz as the first optical anisotropic element, use a positive B plate with nz>nx>ny as the second optical anisotropic element, and change the first The simulation was carried out for the wavelength dispersion R450 / R550 of the retardation of the optical anisotropic element and the second optical anisotropic element. The characteristics and simulation results of the optical anisotropic element used in each example and comparative example are shown in Figure 7 middle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com