A comprehensive evaluation method for the causes of radiation aging damage of engineering plastics used in nuclear power

A technology for engineering plastics and damage causes, which is applied in the field of nuclear power equipment material testing, and can solve problems such as performance aging, hazards, and radiation aging damage without characterization means and analysis systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1: Causes and analysis of aging damage under irradiation dose conditions

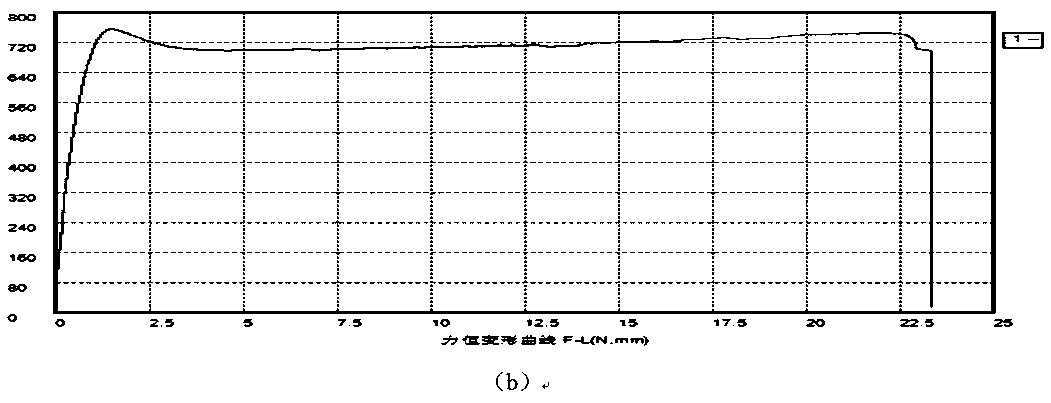

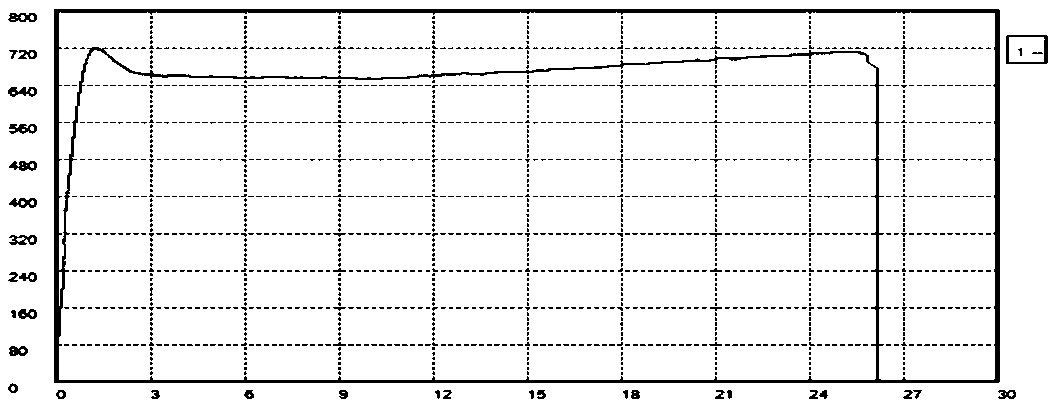

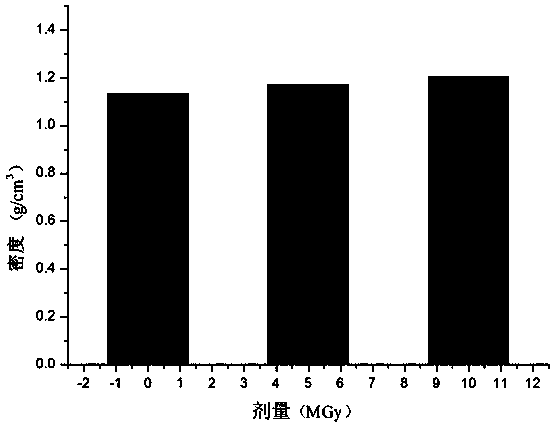

[0040] Figure 1 shows the tensile force value deformation curve of polyetheretherketone (PEEK) before and after electron beam irradiation. It can be seen that the tensile curve of PEEK belongs to the standard saddle curve, which goes through stages of elastic deformation, yield (necking), large deformation and strain hardening (Fig. 1(a)). In the elastic deformation stage of the material, the stress of the material increases rapidly, while the strain change is relatively small, and the elastic modulus is high. It is worth noting that the elastic modulus of the irradiated material decreases and the stress value increases (Fig. 1(b)). At the same time, the density of the material increased after irradiation (figure 2 ). It is obvious that the material has a certain radiation aging phenomenon after irradiation.

[0041] Using 3DSM and SEM methods, the surface and tensile fracture of the s...

Embodiment 2

[0045] Example 2: Causes and Analysis of Aging Damage Under Irradiation Dose Rate Conditions

[0046] Fig. 8 shows a tensile force value deformation curve before and after the gamma ray irradiation dose rate condition. It can be seen that the elongation at break of the polyether ether ketone material decreases before and after irradiation under this condition, and the mechanical properties of the material have certain aging damage.

[0047] Further use SEM to observe the micro-morphology of the tensile section. It can be observed that the interior of the material is also divided into two areas, there are semicircular dissociation surfaces at the upper and lower edges, and the cracks extend from the surface to the inside; the structure in the right half is loose, the surface is uneven, and it is a ductile area ( Figure 9 (a)). The stretch lines on the cleavage surface are white due to the force, and the deformation can be seen after zooming in ( Figure 9 (b), (c)), this is...

Embodiment 3

[0050] Example 3: Causes and analysis of aging damage at irradiation temperature

[0051] Fig. 11 shows the deformation curves of the tensile force value of polyetheretherketone before irradiation at room temperature and after irradiation with gamma rays at 80°C. It can be seen from the comparison that the tensile strength and elongation at break of the material before and after irradiation under this condition do not change much, and the aging degree of the mechanical properties of the material is not obvious.

[0052] Then use SEM to observe the tensile fracture morphology under the irradiation conditions, as shown in Figure 12 shown. It can be seen from the figure that the starting position of the tensile fracture after the irradiation condition is also on the surface of the sample, and the fracture is a semicircular cleavage plane, on which there are radial cracks ( Figure 12 (b)), which belongs to the characteristics of cleavage fracture; the crack edge also has bendi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com