Series-parallel excitation device for vibrating table

An excitation device and parallel technology, applied in the field of testing, can solve problems such as large resistance value, water leakage at the faucet end, potential difference, etc., and achieve the effect of reducing voltage value, ensuring reliability, and slowing down the speed of electrochemical corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

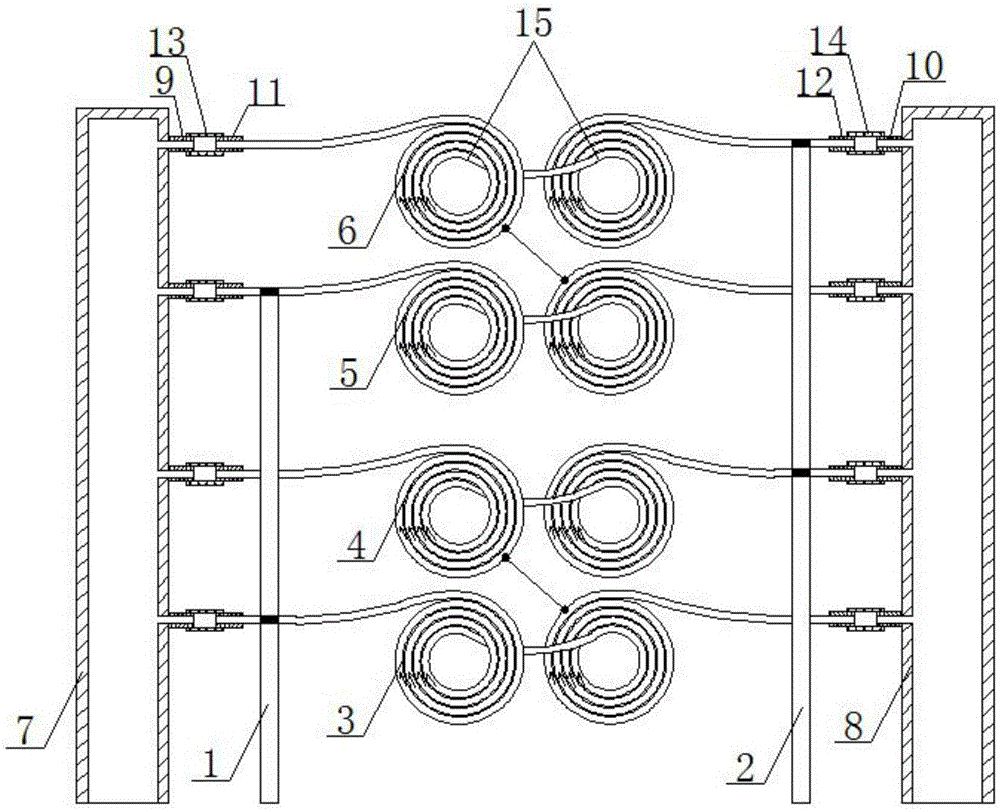

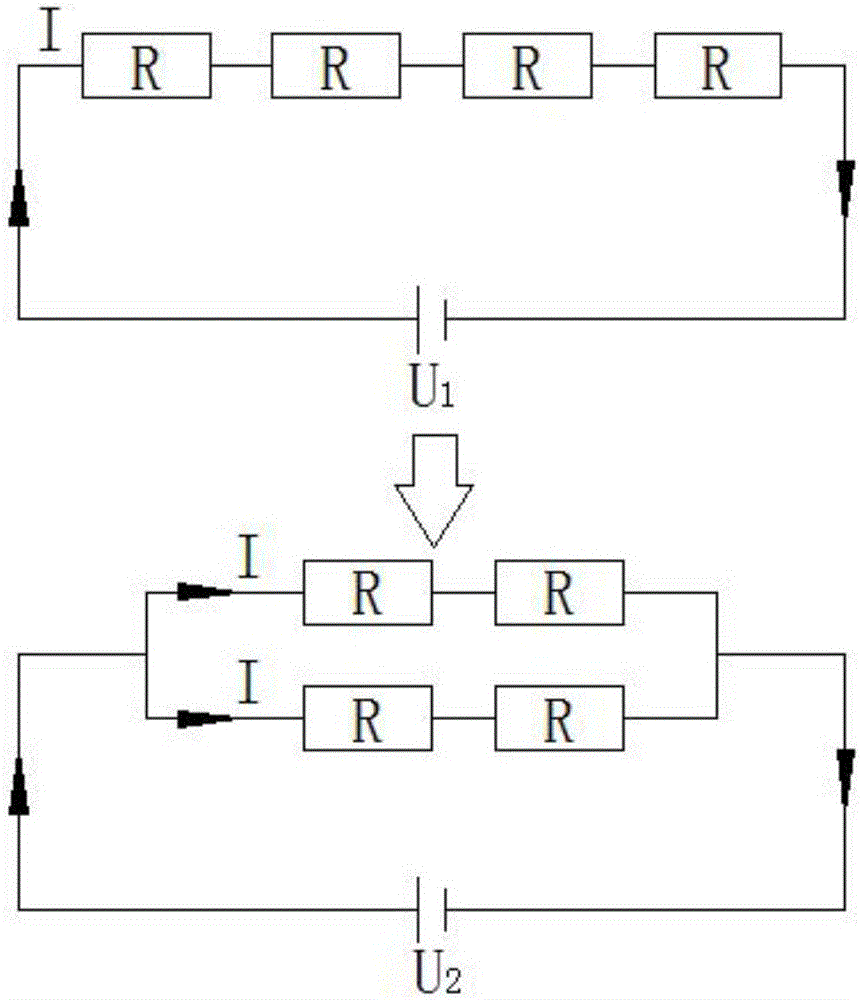

[0017] see figure 1 and figure 2 , as shown in the legend, a series-parallel excitation device for a vibrating table, including a power supply, an excitation coil, and a cooling mechanism;

[0018] The above-mentioned power supply includes a conductive positive electrode 1 and a conductive negative electrode 2;

[0019] The above excitation coil includes the first winding 3, the second winding 4, the third winding 5 and the fourth winding 6 arranged in sequence along the longitudinal direction, the end of the first winding 3 and the head end of the second winding 4 are welded together to form the upper excitation coil. The series connection; the end of the third windin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com