Verticality and symmetry degree testing tool for piston pin hole

A piston pin hole and verticality technology, which is applied in angle/taper measurement, measuring devices, instruments, etc., can solve the problems of insufficient precision, inability to detect accurately with a hand-held piston pin hole verticality tester, and inconvenient operation. To achieve the effect of simple structure of the inspection tool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

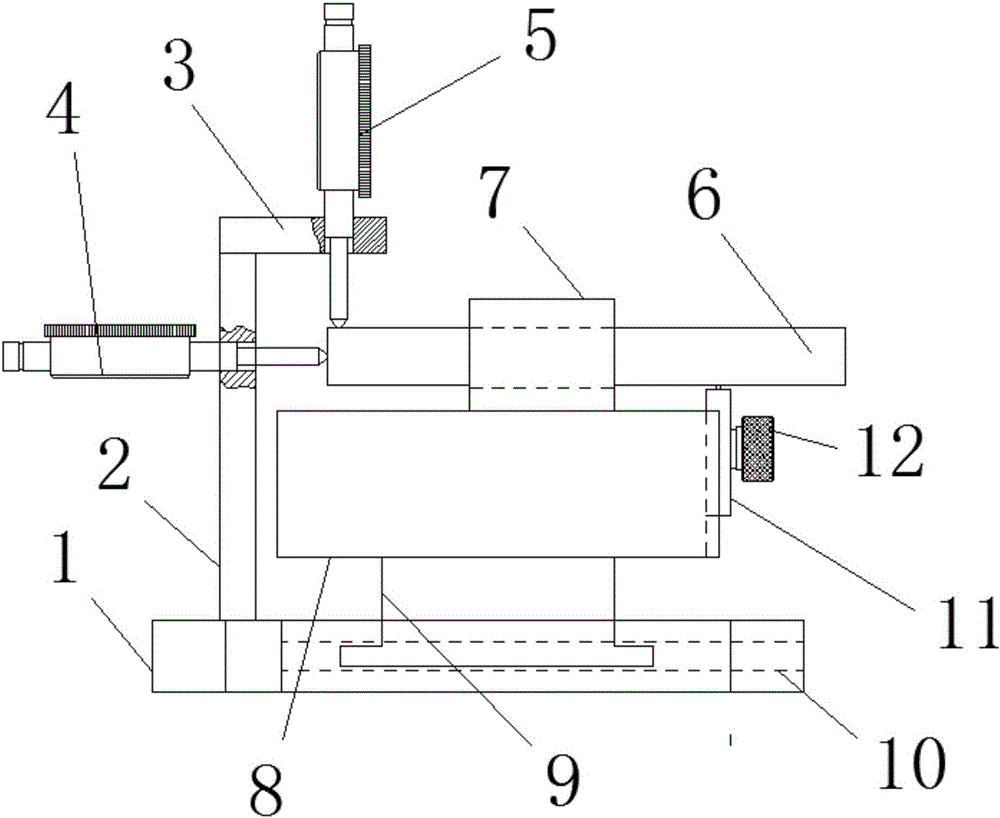

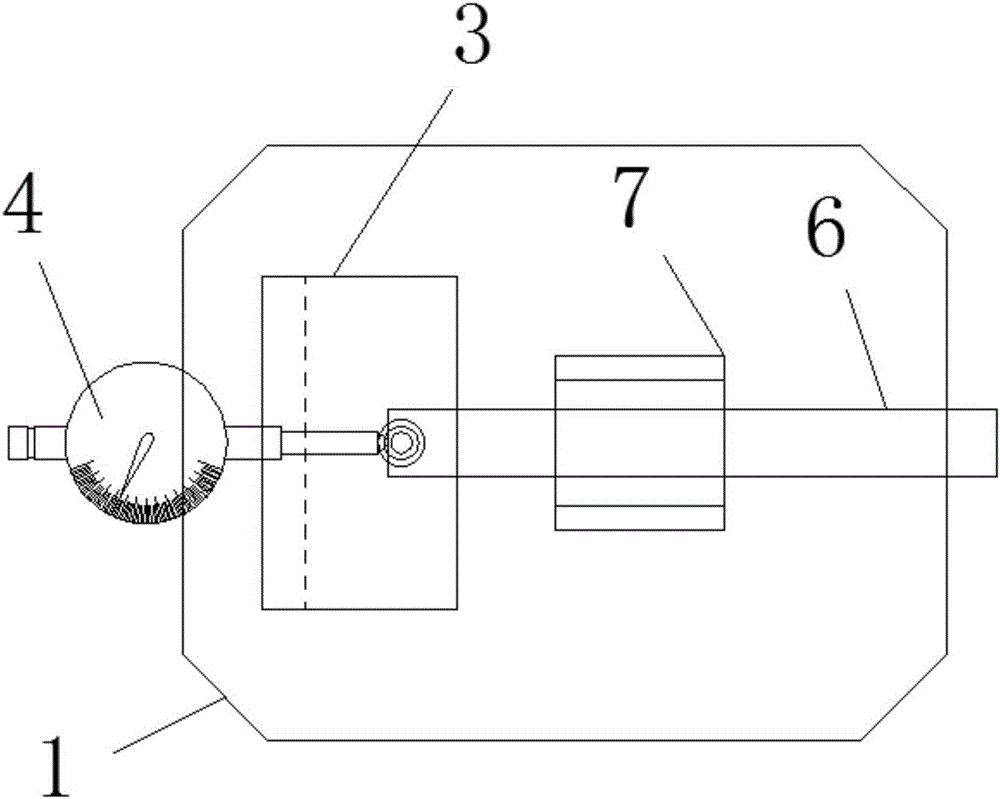

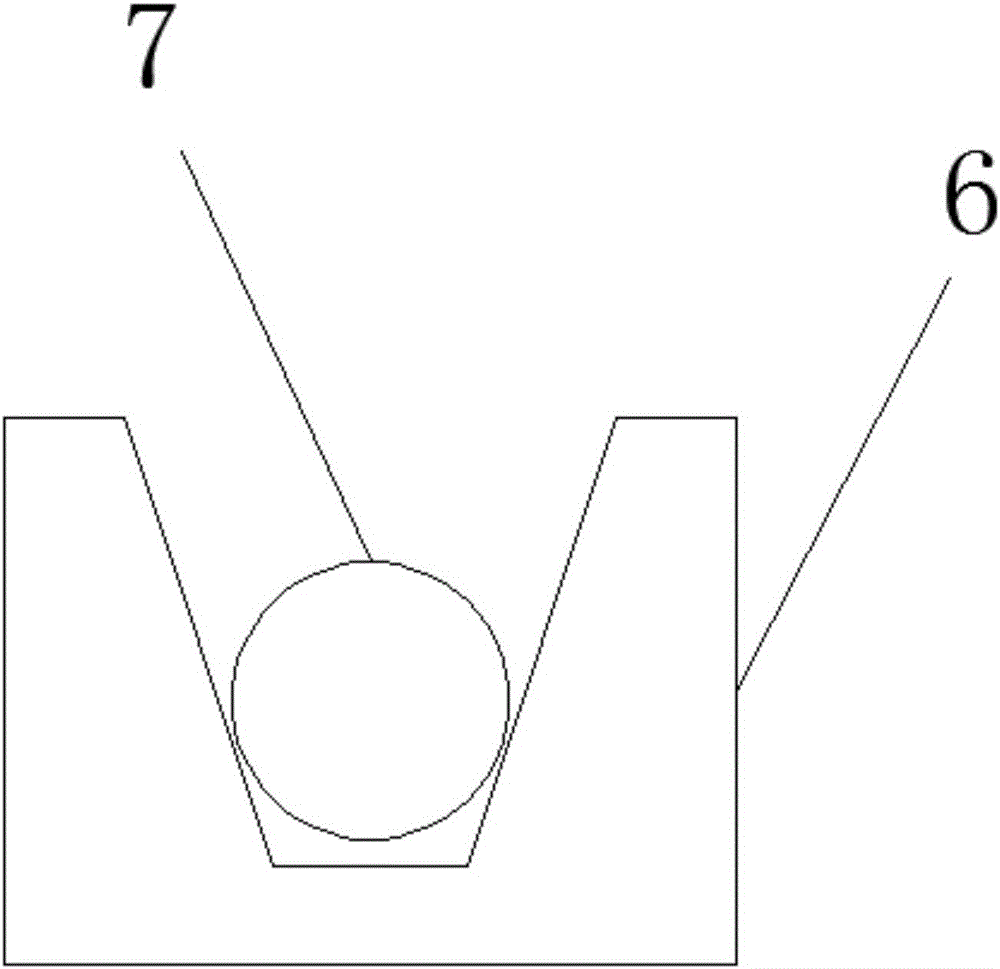

[0014] see Figure 1-3 , the present invention provides a technical solution: a piston pin hole vertical symmetry tester, including a bottom plate 1 and a first connecting plate 2, one end of the bottom plate 1 is vertically connected to one end of the first connecting plate 2, and the second The other end of a connecting plate 2 is vertically connected to the second connecting plate 3, the first connecting plate 2 is inserted with a first dial indicator 4, and the second connecting plate 3 is inserted with a second dial indicator 5 , the head of the first dial indicator 4 bears against the circular end face of the detection mandrel 6, the head of the second dial indicator 5 bears against the side of one end of the detection mandrel 6, and the detection mandrel 6 is placed on two Between the V-shaped blocks 7, two V-shaped blocks 7 are fixedly connected to the upper end surface of the base 8, and the lower end surface of the base 8 is fixedly connected to the connecting seat 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com