High-efficiency energy-saving fan

A high-efficiency energy-saving fan technology, applied in mechanical equipment, engine functions, machines/engines, etc., can solve the problems of low overall fan efficiency, reduced production efficiency, high gas loss, etc., to improve fan efficiency, improve efficiency, and reduce energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

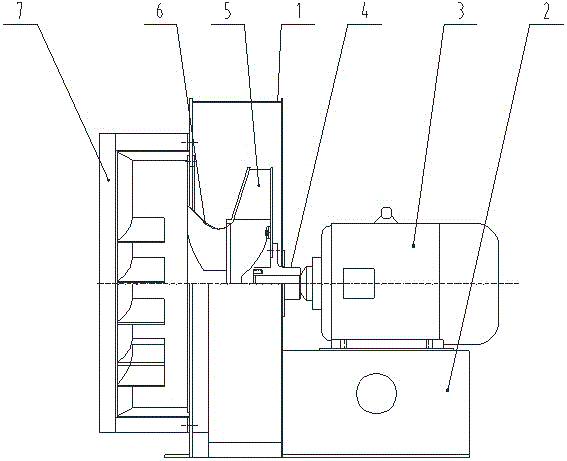

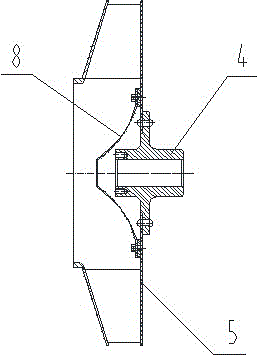

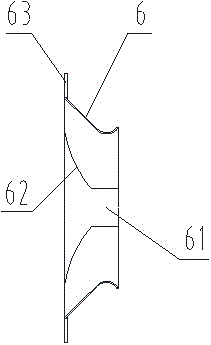

[0024] like figure 1 As shown, the high-efficiency energy-saving fan of the present invention includes a casing 1, a base 2 and a motor 3 installed on the base 2, the output end of the motor 3 is connected with a shaft sleeve 4, and the shaft sleeve 4 can rotate synchronously with the output shaft of the motor; The casing 1 is provided with an air inlet chamber 6 and the impeller 5 in sequence, and the outer edge of the shaft sleeve 4 is fixedly connected to the back plate of the impeller 5 by bolts to drive the impeller to rotate; the air inlet side of the casing 1 is provided with an air inlet box 7. The air inlet of the air inlet chamber 6 communicates with the air outlet of the air inlet box 7, and the air outlet of the air inlet chamber 6 communicates with the air inlet of the impeller 5. When working, the gas first passes through the air inlet box 7, and then passes through the air inlet chamber 6 enters the impeller 5, after being pressurized in the impeller 5, it is di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com