Multi-stage dry Roots vacuum pump

A Roots vacuum pump, dry technology, applied in the direction of rotary piston pump, pump, pump components, etc., can solve the problems of not adapting to the requirements of energy saving, environmental protection and low emission, limited vacuum degree, large volume, etc., to achieve compact structure and installation. Aspect, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

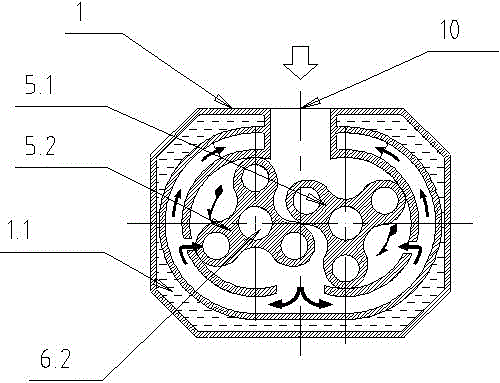

[0026] see Figure 1~4 , the present invention relates to a multi-stage dry Roots vacuum pump, the multi-stage dry Roots vacuum pump includes a pump body 1, the pump body 1 includes a cooling water spacer 1.1 wrapped in the outer layer, the The inner chamber of the pump body 1 is divided into multiple independent pump chambers along its axial direction, and each pump chamber includes an inner chamber 1.2 and an outer chamber 1.3 between the inner chamber 1.2 and the cooling water spacer 1.1 (inner chamber 1.2 and the outer cavity 1.3 are connected to each other), and the inner cavity 1.2 of the adjacent pump cavity is connected to the outer cavity 1.3 (the inner cavity 1.2 is the suction cavity, and the outer cavity 1.3 is the exhaust cavity, such as Figure 4 As shown, the exhaust chamber of the previous pump chamber is connected with the suction chamber of the latter pump chamber);

[0027] A shaft 6 is pierced through the pump body 1, and a plurality of pairs of rotors 5 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com