Vacuum air intake rubber hose for diesel engine

A diesel engine and hose technology, applied in engine components, machines/engines, combustion air/combustion-air treatment, etc., to avoid fluctuations in intake air and ensure performance stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

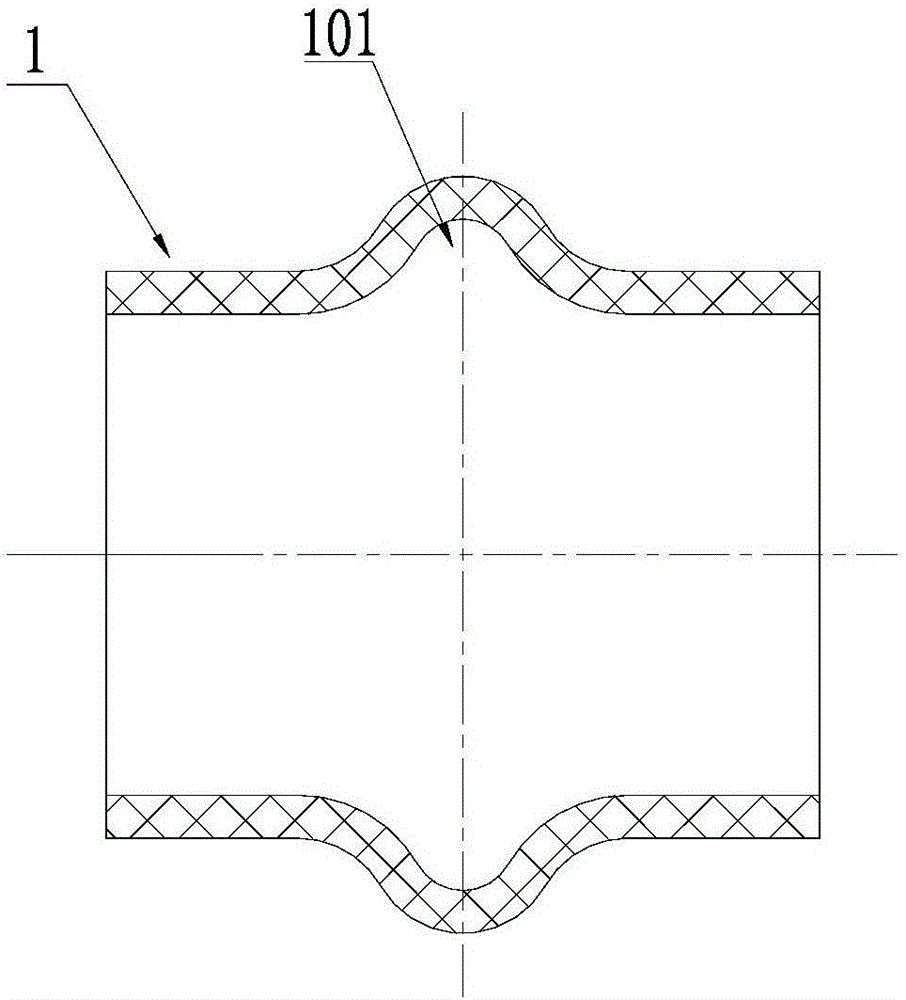

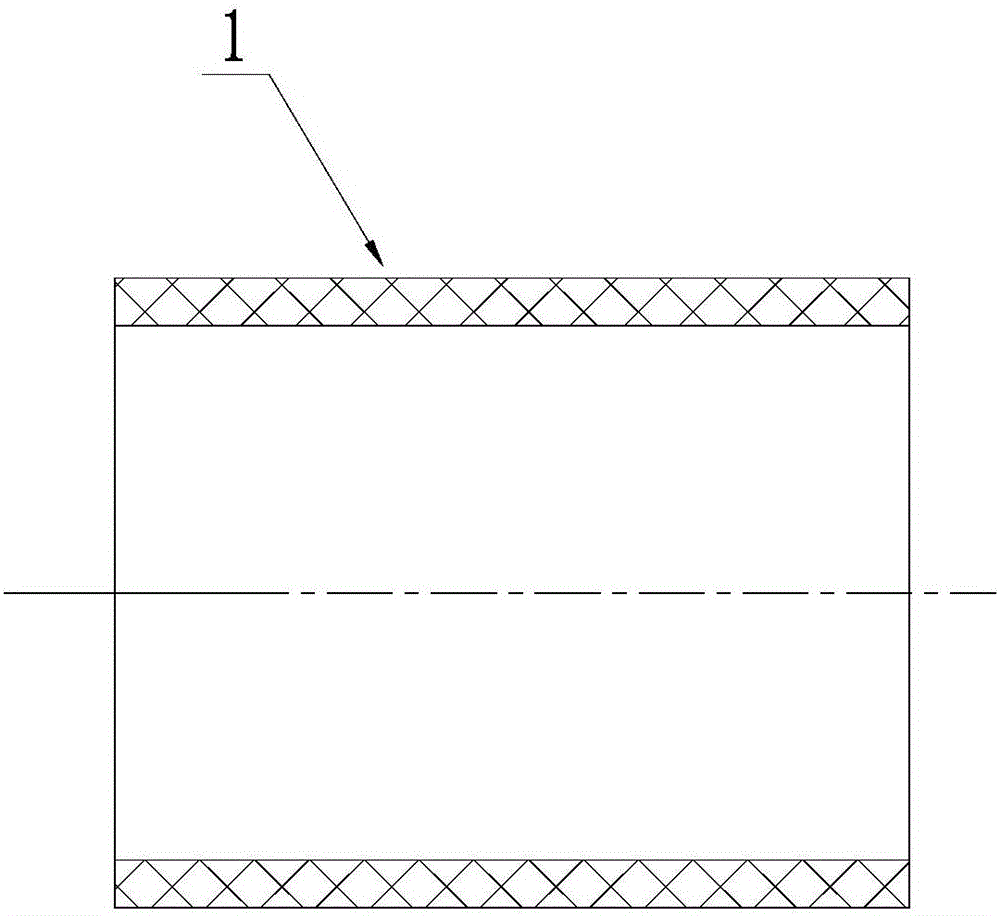

[0011] see figure 1 , a vacuum intake rubber hose for a diesel engine, comprising a rubber hose body 1, the rubber hose body is provided with at least one deformation cavity 101 along the length direction of the rubber hose body, the inner diameter of the deformation cavity is larger than the inner diameter of the rubber hose body, the The outer wall of the rubber hose body at the position of the deformation chamber forms a protrusion, and the two ends of the protrusions are respectively in a smooth transition with the outer wall of the rubber hose body. arc transition. Adopting the above-mentioned technical solution, that is, a variable-diameter deformation chamber is set on the traditional equal-diameter rubber hose, which effectively pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com