Split type universal reset stirring shaft device

A split-type, shaft-device technology, applied in the field of anti-theft locks, can solve problems such as locks not opening, failure to ensure the normal use of the clutch mechanism, and no products available.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

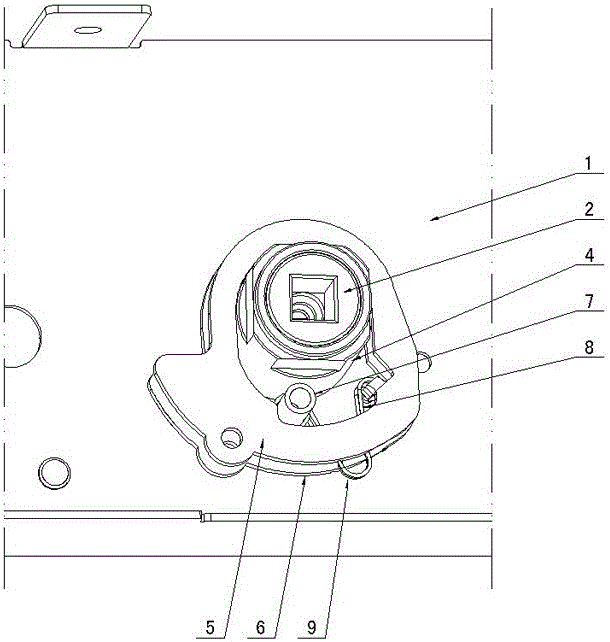

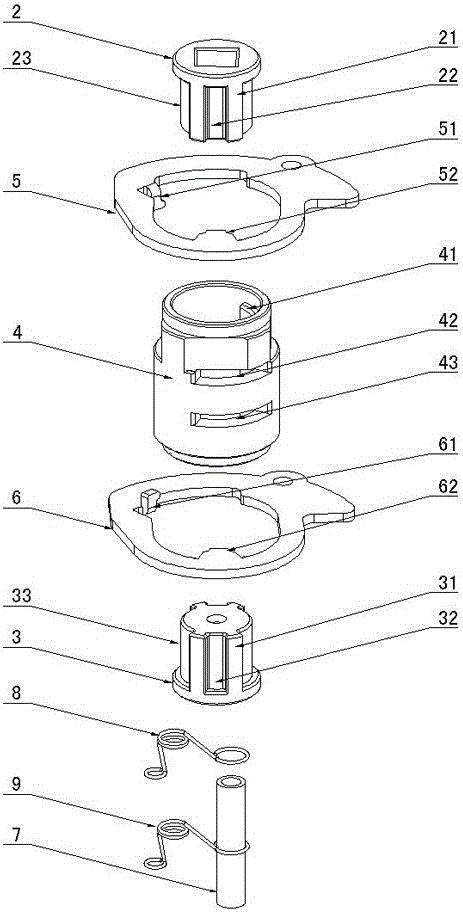

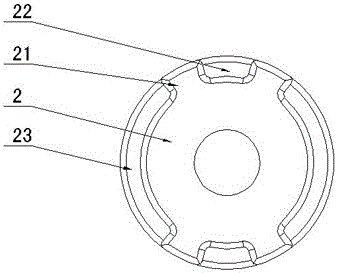

[0017] figure 1 with figure 2 As shown, the present invention creates a specific embodiment of a split-type universal reset dial shaft device, which includes first and second dial shaft cores 2, 3, dial shaft sleeves 4, first and second drive plates 5, 6 , the first dial shaft core 2 is correspondingly provided with a first limit block 21, first and second limit grooves 22, 23, and the second dial shaft core 3 is correspondingly provided with a second limit block 31, The third and fourth limiting grooves 32, 33, the first and second driving plates 5, 6 are correspondingly provided with first and second projections 52, 62, and the inner walls of the two ends of the dial shaft sleeve 4 are symmetrically provided with dial shafts Set the limit block 41, the first and second slots 42, 43 communicating with the inner hole are arranged outside the dial shaft sleeve 4, and the first and second dial shaft cores 2, 3 are symmetrically installed on both ends of the dial shaft sleeve 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com