Automatic wall face plastering device for building

A construction automatic and painting technology, which is applied in the direction of construction and building construction, can solve the problems of manual painting such as shaking, uneven painting degree, and poor painting stability, so as to achieve good painting stability and no need for manual painting and painting fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

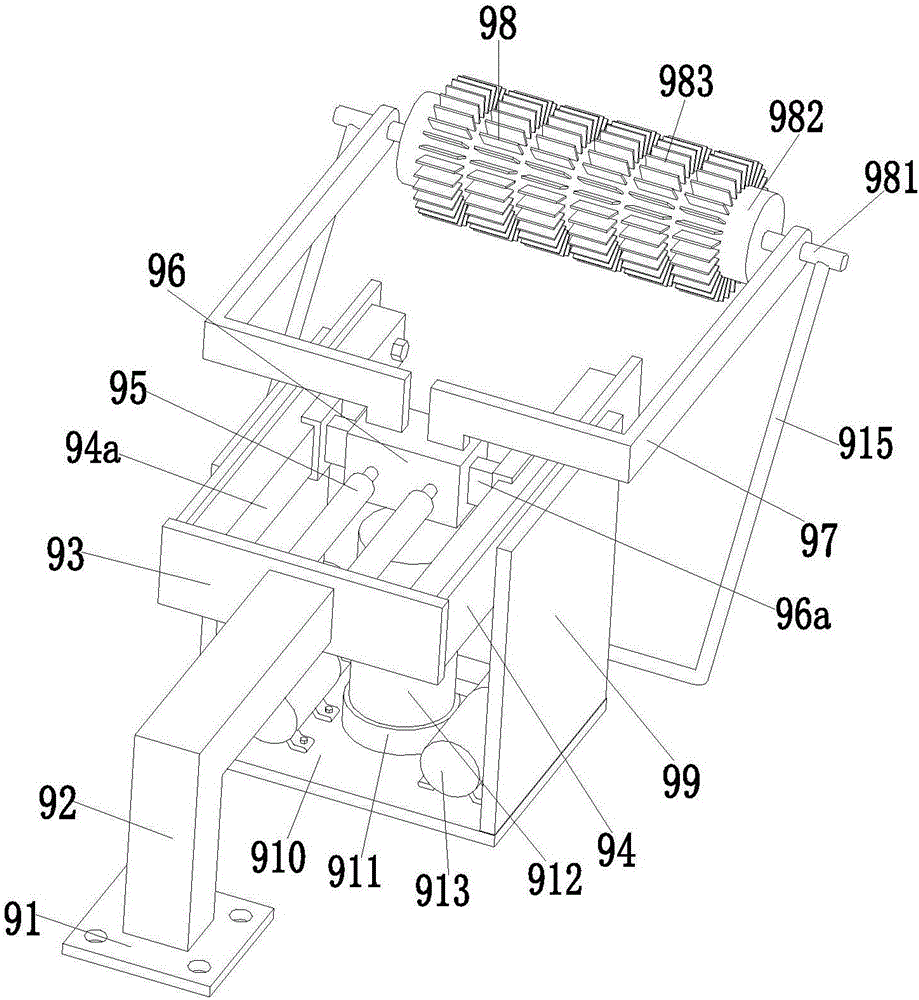

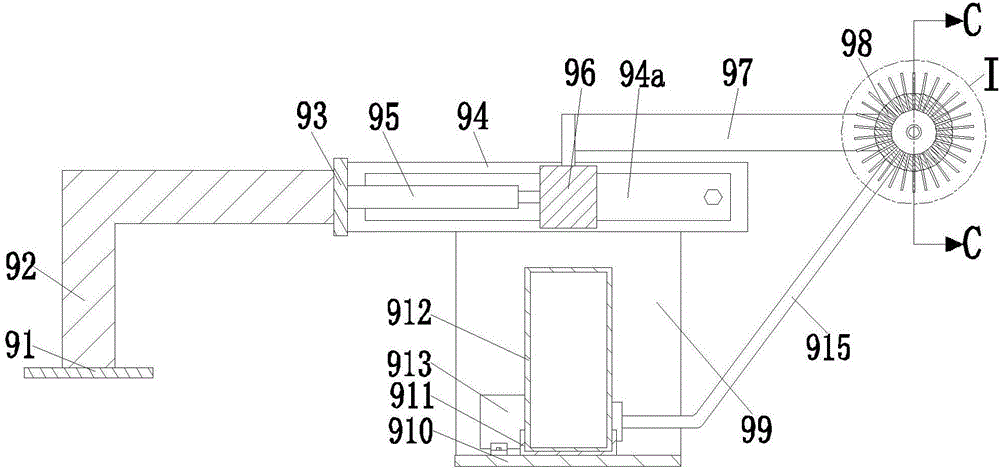

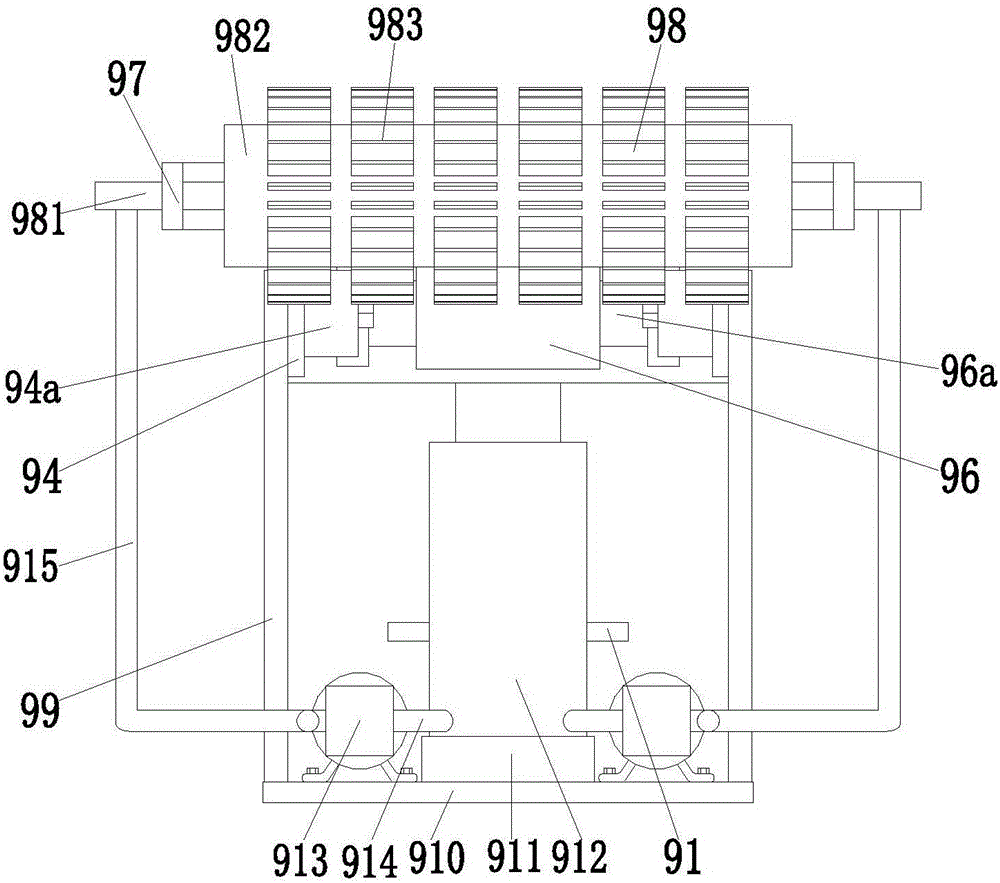

[0018] Such as Figure 1 to Figure 5As shown, a building automatic wall painting device includes a fixed piece 91, a painting support 92 is welded to the middle of the upper end of the fixing piece 91, a painting support plate 93 is welded to the end of the painting support 92, and the two ends of the inner wall of the painting support plate 93 There are two painted baffles 94 symmetrically welded, and two No. 2 linear slide rails 94a are respectively installed with screws on the inner walls of the two painted baffles 94; Cylinder 95, the top of two No. 2 hydraulic cylinders 95 is equipped with painting slider 96, the two ends of painting slider 96 are symmetrically welded with two painting sliding columns 96a, and the ends of two painting slidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com