A high-efficiency quicklime digestion and dust removal system

A quicklime and digester technology, which is applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems such as poor digestion effect, dust and smoke pollution, and low digestion efficiency of digesters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

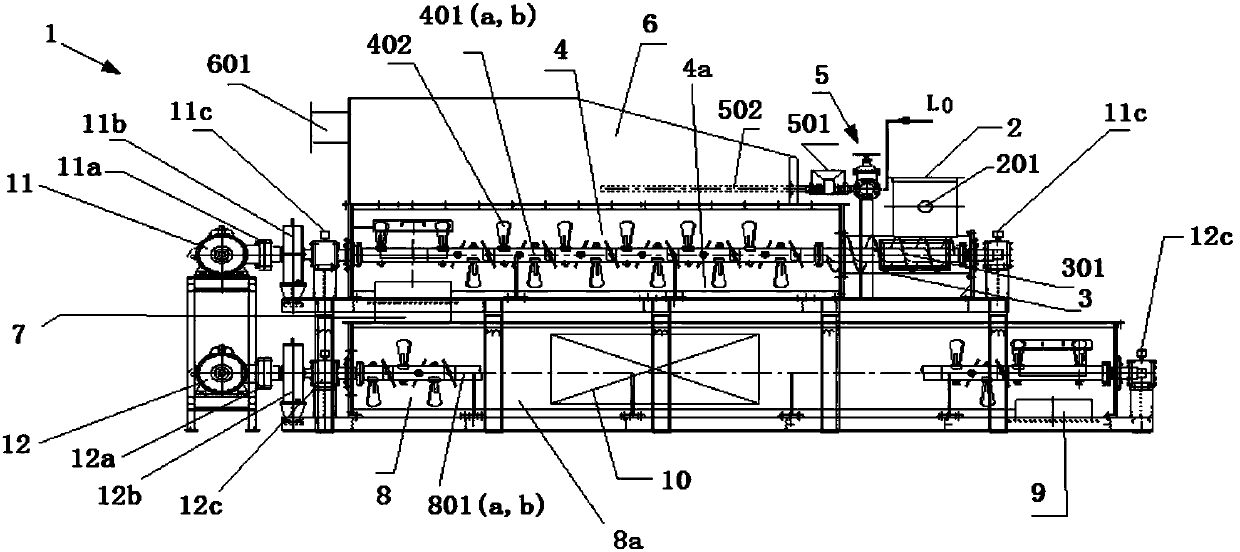

[0170] In this embodiment, a digestion and dust removal device including a two-stage quicklime digester 1 and a dust remover Q1 is used, wherein each rotation axis of the second stage has the same rotation direction as the corresponding rotation axis directly above. The theoretical amount of water required for quicklime digestion is 32wt% of the weight of quicklime. In this embodiment, the rate of spraying water ensures that the amount of sprayed water accounts for 70% by weight of the quicklime weight.

[0171] Quicklime digestion and dust removal method, the method includes the following steps:

[0172] 1) Quicklime digestion: Put the quicklime into the feed port 2 of the two-stage quicklime digester 1, and transport it to the first digestion section box 4 through the sealed conveying section box 3, and pass through the first digestion section box 4 The water spray device 5 on the upper or side of the first digestion section box 4 sprays water to the quicklime material moving in...

Embodiment 2

[0178] Repeat Example 1, using a digestion and dust removal device including a two-stage quicklime digester 1 except that each rotation axis of the second stage rotates in the opposite direction to the corresponding rotation axis directly above.

[0179] After 10 days of continuous operation, there was no blockage of the discharge port.

[0180] The dust removal effect of the dust collector Q1 is higher than 99.6%.

[0181] During normal operation, samples are taken from the outlet 9 at the bottom of the quicklime digester 1 at the same time interval of 20 seconds for analysis.

Embodiment 3

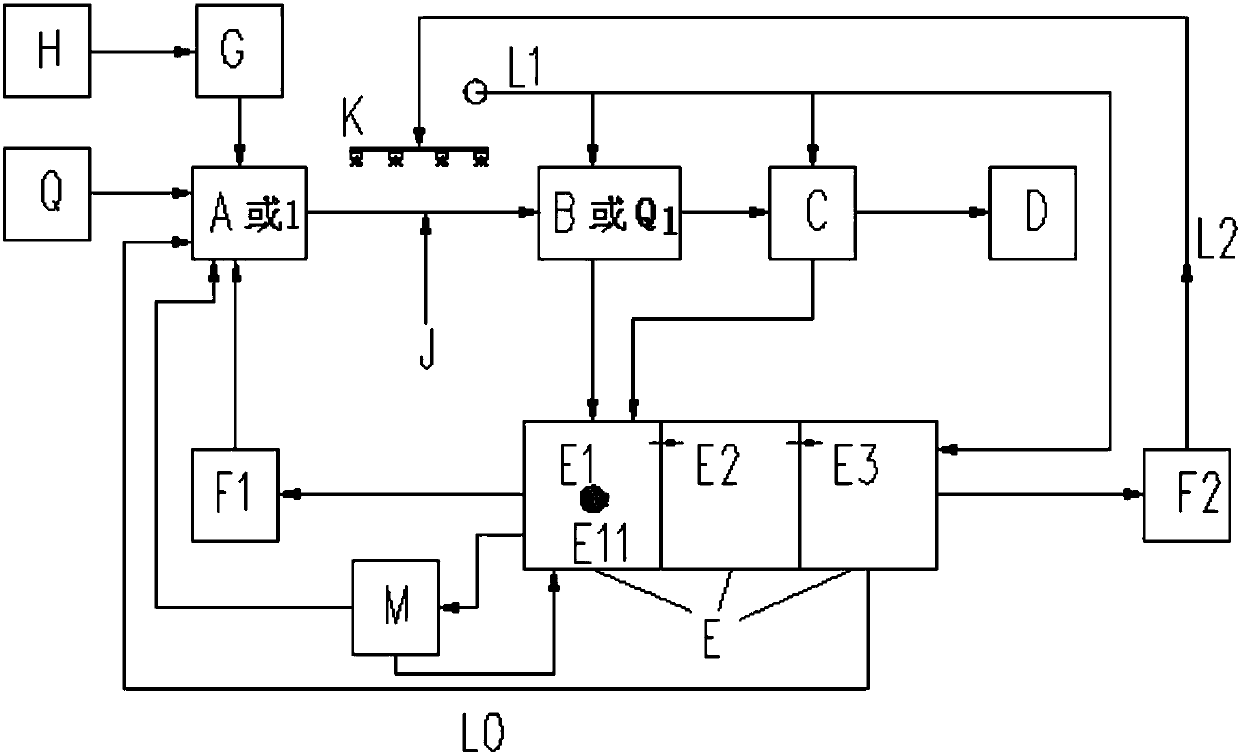

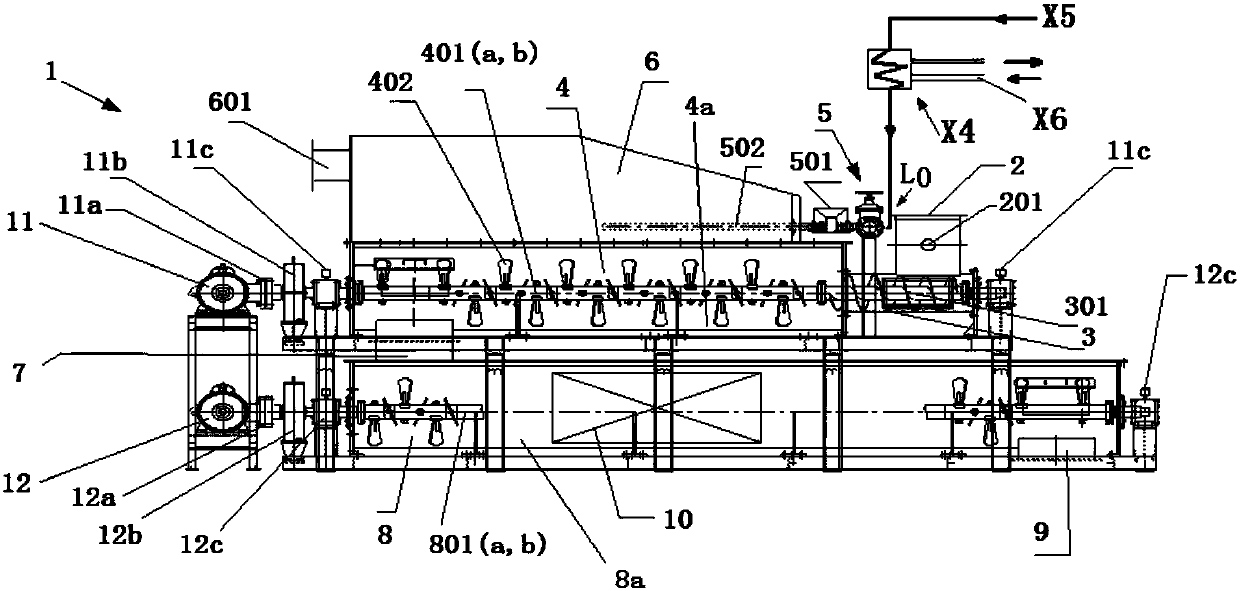

[0185] A high-efficiency quicklime digestion and dust removal system, which includes a digester 1, a water bath dust collector Q1, an exhaust device A1, a chimney A2, a dust removal sewage treatment device A3, a sludge treatment device A4, a cleaning device A5, and a slaked lime conveying device A6 and Mixer A7, water bath dust collector Q1 is connected with the dust collection port 601 of digester 1 through a dust removal pipe Q4; slaked lime conveying device A6 is located at the outlet 9 of digester (1), and mixer A7 is connected with slaked lime Conveying device A6 is connected, the clean air outlet Q303 of the water bath dust collector Q1 is connected to the chimney A2 through the exhaust device A1, the overflow pipe Q502 of the water bath dust collector Q1 is connected to the dust removal sewage treatment device A3, and the sewage sludge discharge device at the bottom of the dust removal pool Q2 Q203 is connected to the sludge treatment device A4, and the dust removal sewag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com