A kind of single-layer kiln color-changing glaze and preparation method thereof

A single-layer, glaze technology, applied in the field of ceramics, can solve the problems of high production cost of kiln-changed glaze, unsuitable for batch ceramic industrial production, etc., and achieve the effect of improving single product structure, low cost, and improving market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] As a preferred embodiment of the present invention, a method for preparing a single-layer kiln-changing glaze comprises the following steps:

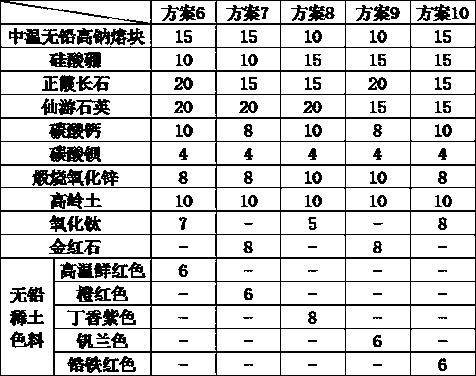

[0023] Ⅰ. Preparation of glaze: 10-15 parts of medium-temperature lead-free high-sodium frit, 10-15 parts of borosilicate, 15-20 parts of nepheline, 15-20 parts of quartz, 8-10 parts of calcium carbonate, 4 1 part of barium carbonate, 8-10 parts of calcined zinc oxide, 10 parts of kaolin, 5-10 parts of titanium oxide or rutile, 2-8 parts of colored oxides or lead-free ceramic pigments are mixed to make a mixture, and then proportioned by weight It is a mixture: water = 1:0.75-0.85, add water, and make glaze after ball milling. The prepared glaze is passed through a 220-mesh sieve. The above-mentioned colored oxides are one or a combination of copper carbonate, cobalt oxide, manganese oxide, and iron oxide. The above-mentioned lead-free ceramic pigments are lead-free rare earth pigments. The purity of the above-mentioned boron s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com