Operating component gap and relative movement regulation and control device of hollow brick machine

A technology of hollow brick machine and relative movement, which is applied in the direction of ceramic forming machine, auxiliary forming equipment, manufacturing tools, etc., and can solve problems such as poor operation effect, abnormal gap between components or movement direction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

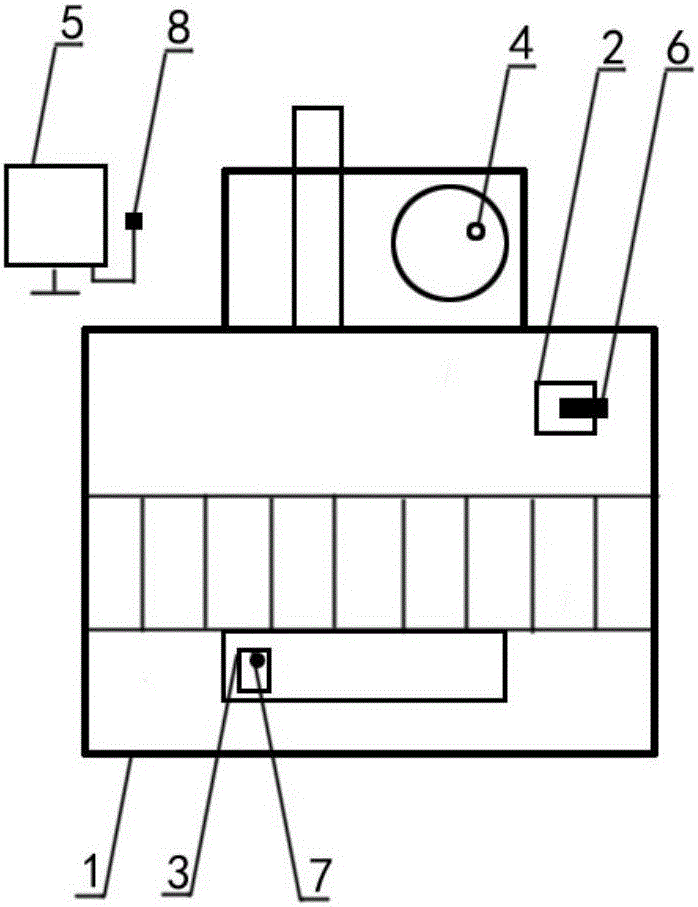

[0012] Embodiment: as shown in the accompanying drawing. The relative movement control device for the gap between the operating parts of the hollow brick machine includes a body (1), and a gap measurement module (2), a speed sensing module (3), an information sensing module (4), and a management module (5) are arranged on the body (1) , during operation, the gap measurement module (2) measures the gap value, the speed sensing module (3) senses the movement speed of related components, and the information sensing module (4) transmits the sensed information to the management module (5) for processing.

[0013] The relative motion control device for the gap between the operating parts of the hollow brick machine is provided with a setting module (6) on the gap measurement module (2) to set the gap situation within the appropriate range of the relevant parts.

[0014] The relative motion control device for the gap between the operating parts of the hollow brick machine is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com