Finish machining auxiliary positioning device for flywheel shell

An auxiliary positioning and finishing technology, applied in the field of mechanical parts processing, can solve problems such as troublesome clamping process, scratches on fixture positioning pins, large volume, etc., to save clamping time, improve work efficiency, and facilitate production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

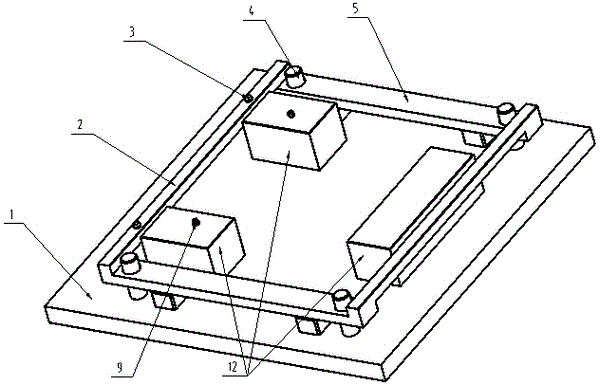

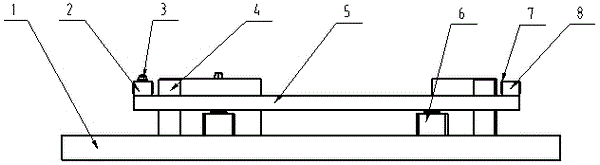

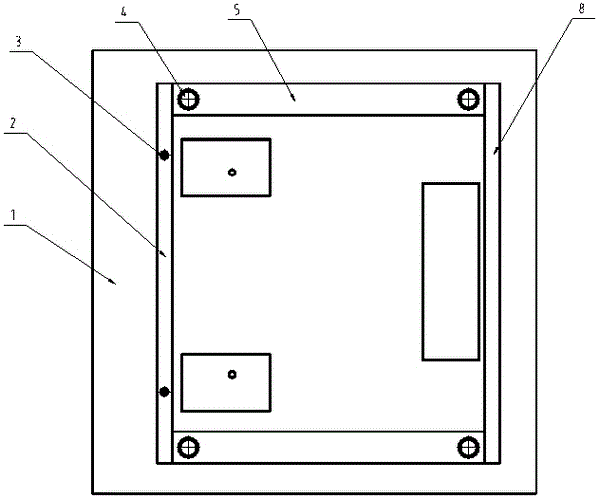

[0020] figure 1 , 2 , 3, the present invention is made up of positioning plate one 2, positioning plate two 8, protective layer 7, pre-positioning pin 3, support rod 5, guide column 4, cylinder 6. The two ends of the positioning plate one 2 and the positioning plate two 8 are connected with the two support rods 5 by welding. The protective layer is fixed on the positioning plate one 2 and the positioning plate two 8 by adhesive, and the protective layer is hard plastic. Two pre-positioning pin holes are arranged on the positioning plate-2, and the pre-positioning pin 3 is connected with the positioning plate-2 through the interference fit of the pre-positioning pin holes. A guide hole is provided on the support rod 5 , and four guide columns 4 are matched with the guide holes in a small gap, and the lower ends of the guide columns are fixed on the fixture body 1 . The cylinder 6 is fixed on the fixture body 1, and the cylinder rod is inserted into the limit hole of the supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com