A hot-melt removal mechanism

A technology of hot-melt and heating components, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of poor separation effect and uncontrollable pulling force, so as to improve the success rate of disassembly, strong versatility, The effect of reducing the viscosity of the colloid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

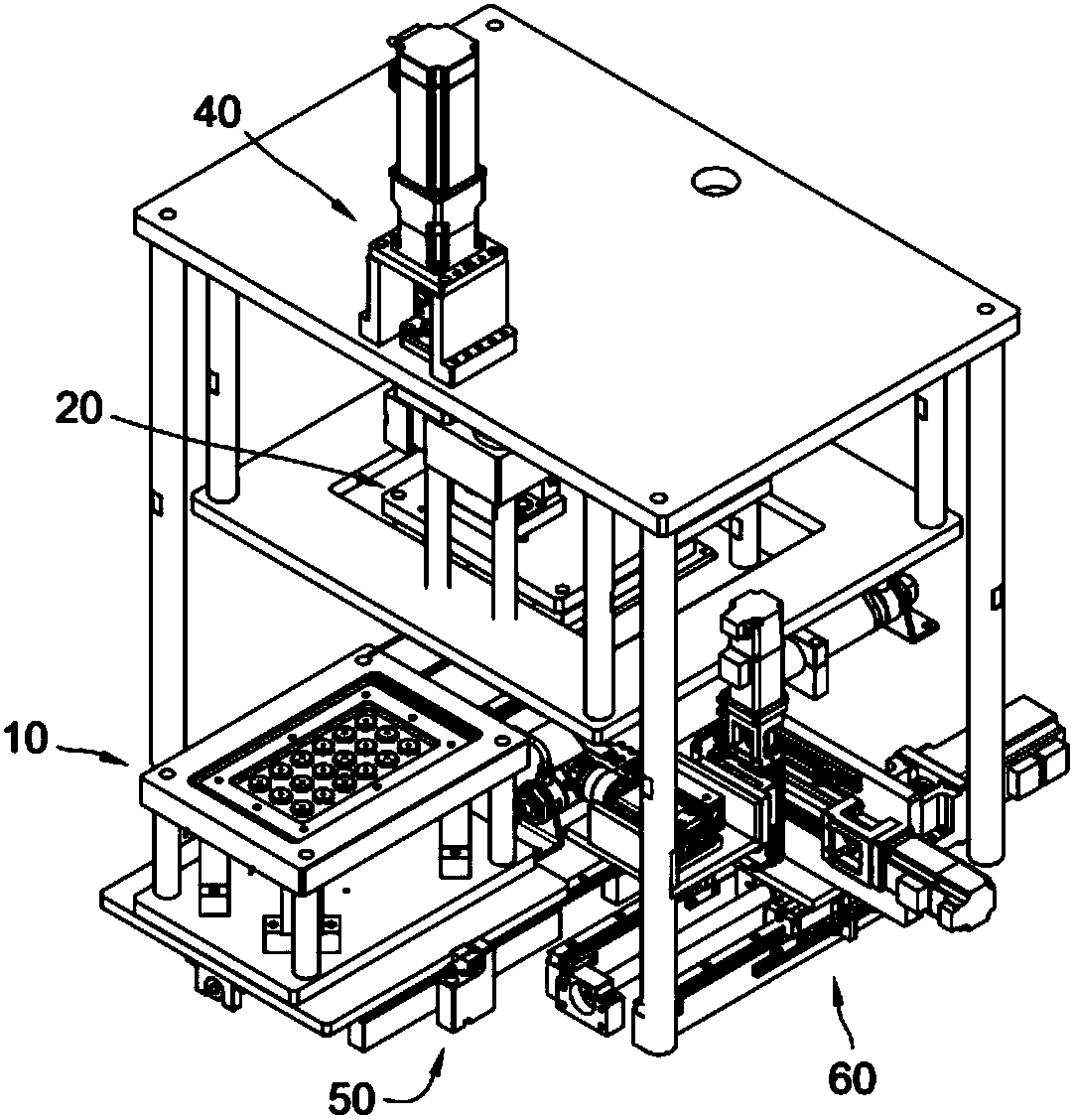

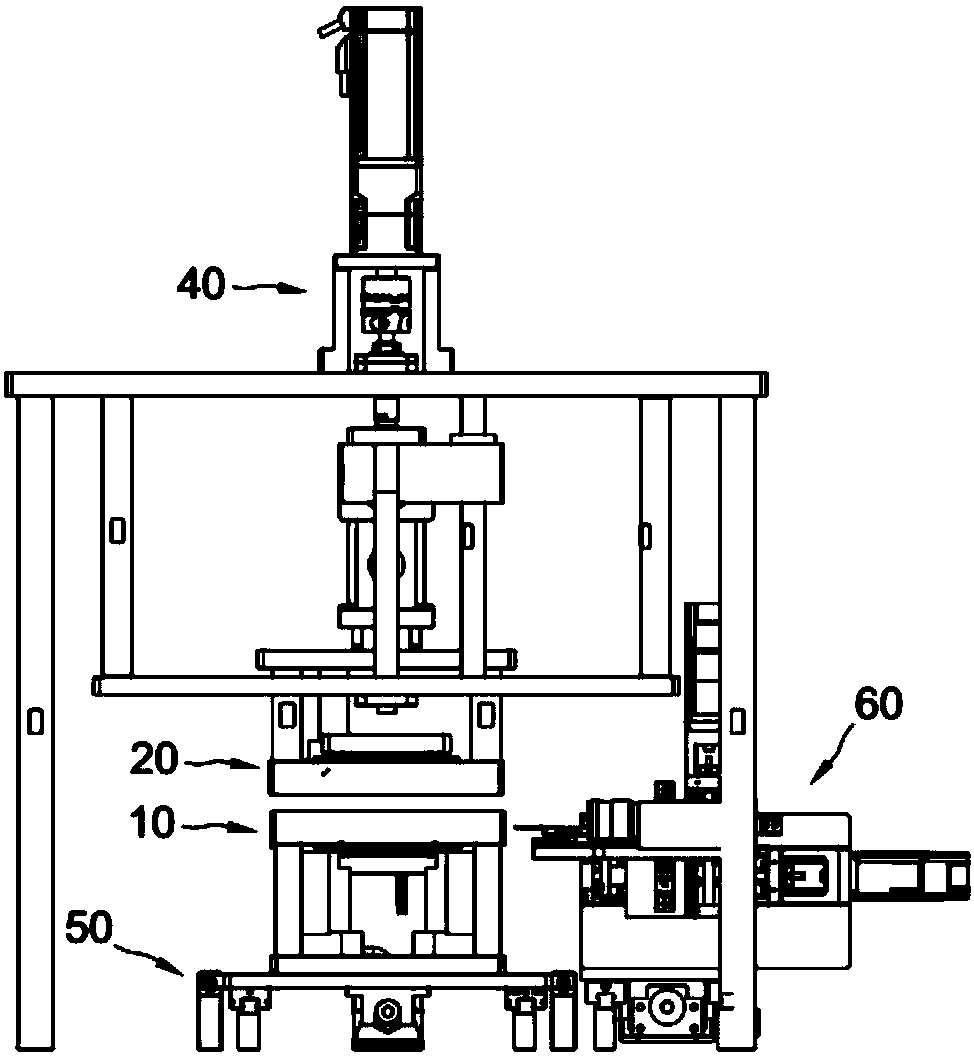

[0035] combine figure 1 , figure 2 , a hot-melt removal mechanism, including a lower heating assembly 10 provided with a product lower surface adsorption device, an upper heating assembly 20 provided with a product upper surface adsorption device, and a stripping assembly 60 arranged beside the lower heating assembly.

[0036] combine figure 1 , figure 2 , the top of the upper heating assembly 20 is connected to the pulling device 40 installed on the frame 30 .

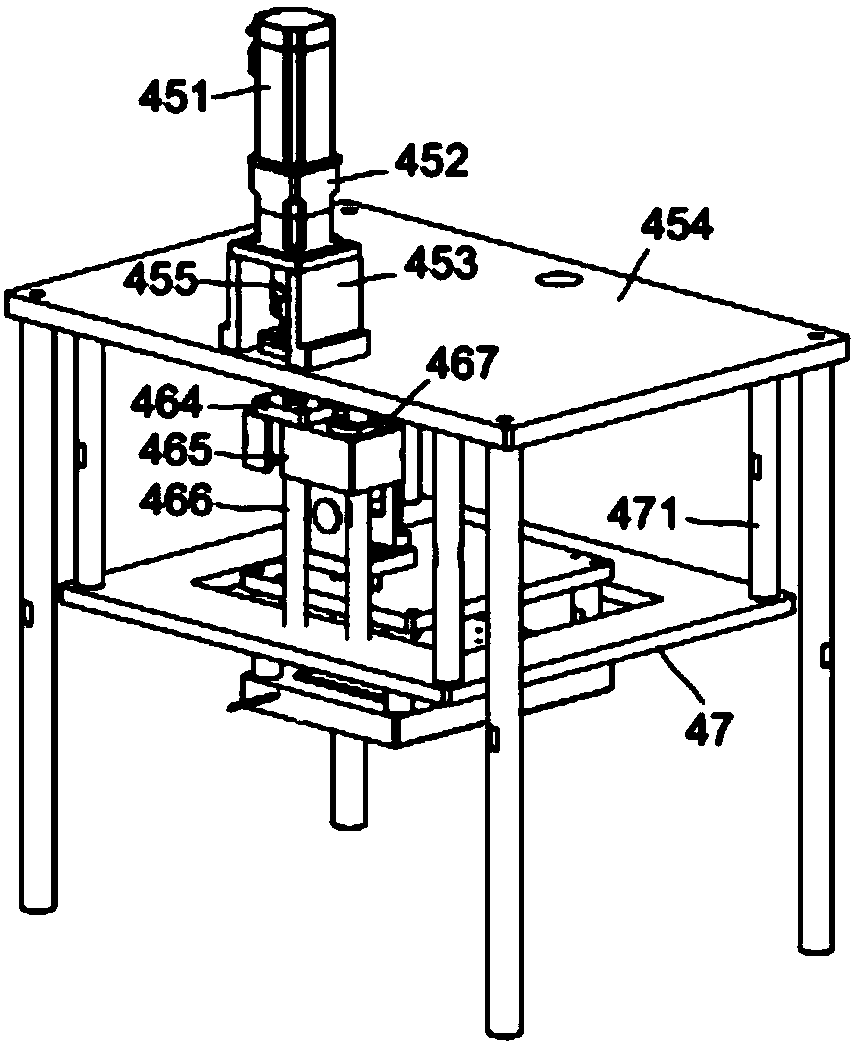

[0037] combine Figure 3 to Figure 5, the drawing device 40 includes a lifting motor 451 , the lifting motor is connected to a reducer 452 , and the reducer is fixedly installed on a motor fixing plate 454 through a lifting motor base 453 . The lifting motor 451 is connected to the lifting screw 461 through the lifting motor coupling 455, the upper end of the lifting screw is rotatably installed on the screw support 462, and the lower end of the lifting screw is rotatably installed at the end of the screw throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com