A method for recycling waste HDDR bonded NdFeB permanent magnets

A neodymium-iron-boron and permanent magnet technology, applied in the direction of magnetic objects, magnetic materials, electrical components, etc., can solve the problems of difficult manufacturing of complex magnets, complicated preparation processes, large quantity of defective products, etc., and achieve major economic and social benefits, The effect of high economic value and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

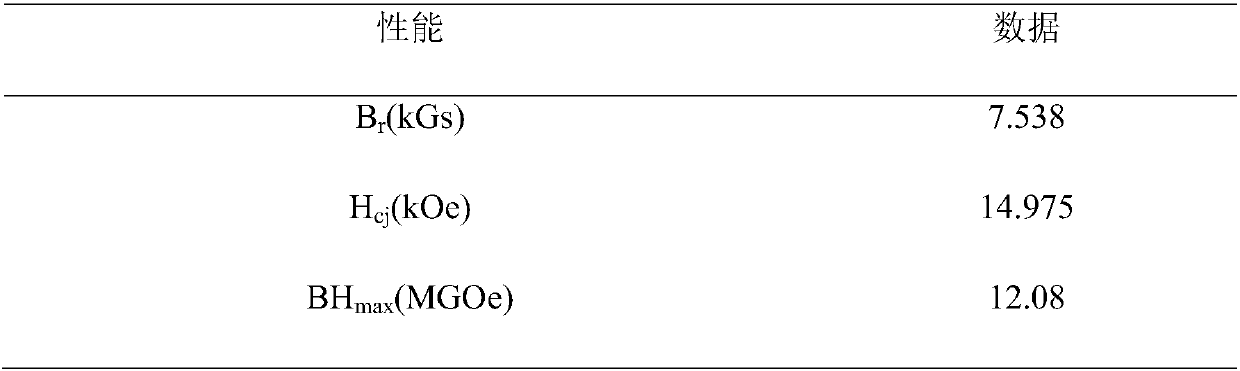

Embodiment 1

[0020] Embodiment 1: A method for recycling waste HDDR bonded NdFeB permanent magnets is carried out according to the following steps.

[0021] The first step is to soak the waste HDDR bonded NdFeB permanent magnet in a mixed solvent for 10 hours, and grind it to obtain waste HDDR magnetic powder A;

[0022] In the second step, the waste HDDR magnetic powder A obtained in the first step is soaked in acetic acid acetone solution (acetic acid concentration 2wt%, the same below) for 3 minutes to remove oxides in the waste HDDR magnetic powder to obtain magnetic powder B;

[0023] In the third step, put the magnetic powder B obtained in the second step into a mixed solvent, heat and soak in a water bath for 8 hours, and ultrasonically oscillate once every two hours for 10 minutes each time to obtain magnetic powder C;

[0024] The fourth step is to put the magnetic powder C obtained in the third step into the mixed solvent, ultrasonically clean it for 10 minutes, and repeat it 5 t...

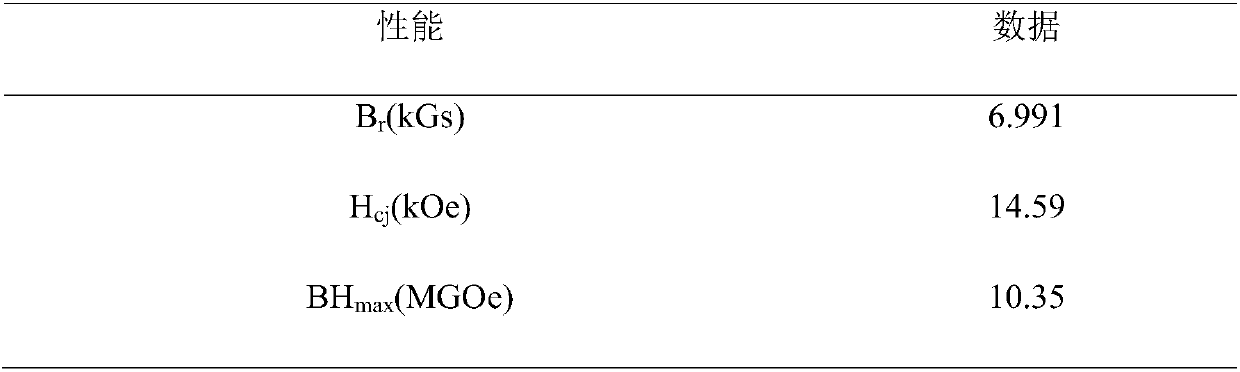

Embodiment 2

[0031] Embodiment 2: A method for recycling waste HDDR bonded NdFeB permanent magnets is carried out according to the following steps.

[0032] The first step is to soak the waste HDDR bonded NdFeB permanent magnet in a mixed solvent for 24 hours, and grind it to obtain waste HDDR magnetic powder A;

[0033] In the second step, the waste HDDR magnetic powder A obtained in the first step is soaked in acetic acid solution for 5 minutes to remove oxides in the waste HDDR magnetic powder to obtain magnetic powder B;

[0034] In the third step, put the magnetic powder B obtained in the second step into a mixed solvent, heat and soak in a water bath for 12 hours, and ultrasonically oscillate once every two hours for 12 minutes each time to obtain magnetic powder C;

[0035] The fourth step is to put the magnetic powder C obtained in the third step into the mixed solvent, ultrasonically clean it for 12 minutes, and repeat it 7 times until the solution is pure and transparent, and the...

Embodiment 3

[0042] Embodiment 3: A method for recycling waste HDDR bonded NdFeB permanent magnets is carried out according to the following steps.

[0043] The first step is to soak the waste HDDR bonded NdFeB permanent magnet in a mixed solvent for 48 hours, and grind it to obtain waste HDDR magnetic powder A;

[0044] In the second step, the waste HDDR magnetic powder A obtained in the first step is soaked in acetic acid solution for 10 minutes to remove oxides in the waste HDDR magnetic powder to obtain magnetic powder B;

[0045] In the third step, put the magnetic powder B obtained in the second step into a mixed solvent, heat and soak in a water bath for 24 hours, and ultrasonically oscillate once every two hours for 15 minutes each time to obtain magnetic powder C;

[0046] The fourth step is to put the magnetic powder C obtained in the third step into the mixed solvent, ultrasonically clean it for 15 minutes, and repeat 10 times until the solution is pure and transparent, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com