Improved bearing cleaning machine allowing inner rings of cleaned bearings to be rotatable

A bearing inner ring, bearing cleaning technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of angle change, high cost, inconvenient use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

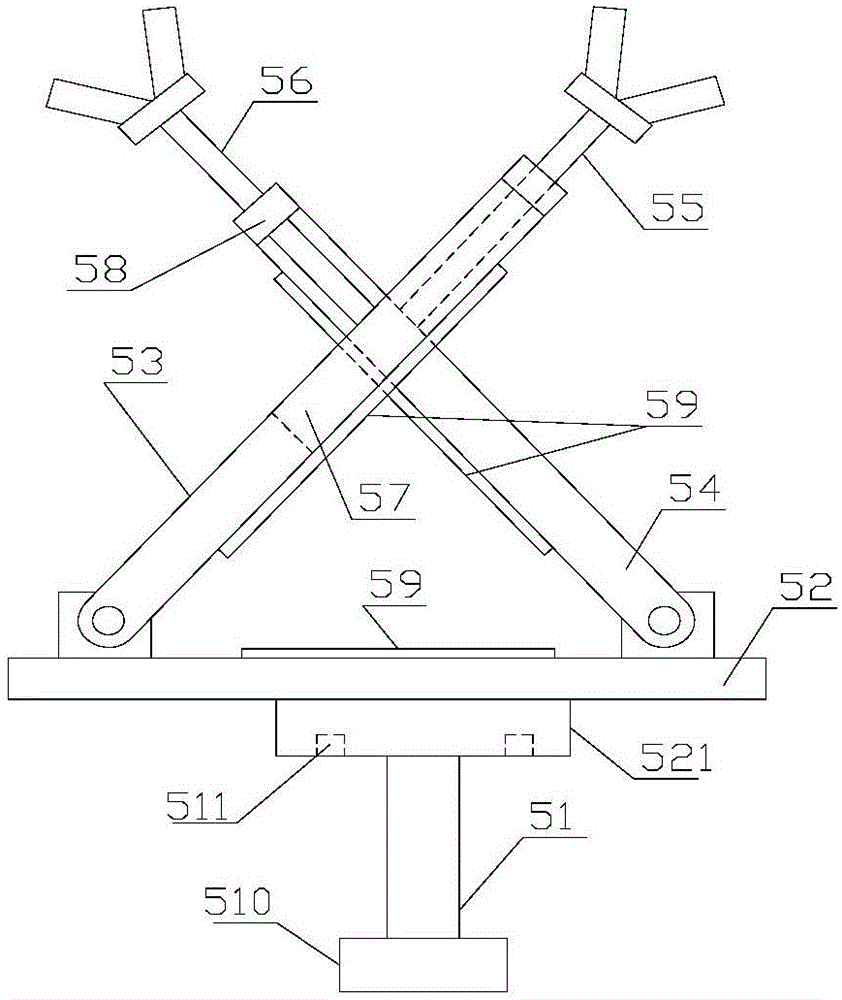

[0016] refer to figure 1 , 2 , the present invention is an improved bearing cleaning machine that can rotate the inner ring of the cleaned bearing, including a cylinder body 1, a motor 2, a partition plate 3, a turntable 4, a plurality of fixing frames 5, a plurality of fixing mechanisms 6, and a drive for the inner ring of the bearing to be cleaned. Rotating driving mechanism 7, pump group 8, several nozzles 10, third cylinder 11, mounting plate 12, upper guide rail 13, lower guide rail 14 and water pipe 15, the cylinder 1 is provided with a partition 3 and a driving mechanism 7, The bottom of the dividing plate 3 is provided with a motor 2, and the rotating shaft of the motor 2 is provided with a rotating disk 4 above the dividing plate 3, and the rotating disk 4 is provided with a fixing frame 5 and a fixing mechanism 6 for fixing the fixing bracket 5, The input end of the pump group 8 communicates with the cylinder 1 above the partition 3, the output end of the pump group...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com