Modified activated aluminum oxide with high fluoride ion adsorption capability, and preparation method thereof

An activated alumina, high adsorption technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, other chemical processes, etc., can solve the problems of increasing regeneration costs, loss of adsorbents, and increasing water production costs, and achieve fluoride removal. The effect of increasing the volume, reducing the processing cost, and considerable application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

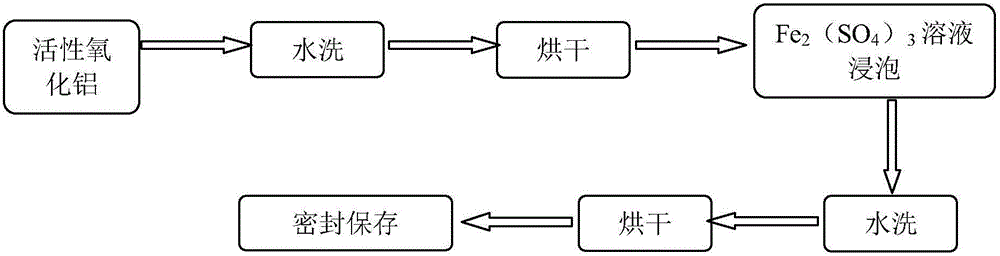

[0028] like figure 1 As shown, the preparation method of modified activated alumina with high adsorption capacity for fluoride ions provided in this example comprises the following steps:

[0029] (1) Select activated alumina, wash it with deionized water until the washing water is no longer turbid, put the cleaned activated alumina in an oven at 105°C for 12 hours, and seal it for future use;

[0030] (2) Weigh 0.6g ferric sulfate solid, adopt deionized water to dissolve and be mixed with 100mL of 15mmol / L ferric sulfate solution;

[0031] (3) the standby active alumina 25g that is made in step (1), put into the ferric sulfate solution that the concentration that prepares in 25mL step (2) is 15mmol / L, discard ferric sulfate solution after soaking 3 hours, After washing with about 100mL of deionized water, dry in an oven at 105°C for 12 hours to obtain a modified activated alumina with high adsorption capacity for fluoride ions, which is sealed and stored for future use.

Embodiment 2

[0033] like figure 1 As shown, the preparation method of modified activated alumina with high adsorption capacity for fluoride ions provided in this example comprises the following steps:

[0034] (1) Select activated alumina, wash it with deionized water until the washing water is no longer turbid, put the cleaned activated alumina in an oven at 105°C for 12 hours, and seal it for future use;

[0035] (2) Weigh 1.2g ferric sulfate solid, adopt deionized water to dissolve and be mixed with 100mL of 30mmol / L ferric sulfate solution;

[0036] (3) the standby active alumina 25g that is made in step (1), put into the ferric sulfate solution that the concentration that prepares in 25mL step (2) is 30mmol / L, discard ferric sulfate solution after soaking 3 hours, After washing with about 100mL of deionized water, dry in an oven at 105°C for 12 hours to obtain a modified activated alumina with high adsorption capacity for fluoride ions, which is sealed and stored for future use.

Embodiment 3

[0038] like figure 1 As shown, the preparation method of modified activated alumina with high adsorption capacity for fluoride ions provided in this example comprises the following steps:

[0039] (1) Select activated alumina, wash it with deionized water until the washing water is no longer turbid, put the cleaned activated alumina in an oven at 105°C for 12 hours, and seal it for future use;

[0040] (2) Weigh 1.8g ferric sulfate solid, adopt deionized water to dissolve and be mixed with 100mL of 45mmol / L ferric sulfate solution;

[0041] (3) the standby active alumina 25g that is made in step (1), put into the ferric sulfate solution that the concentration that prepares in 25mL step (2) is 45mmol / L, discard ferric sulfate solution after soaking 3 hours, After washing with about 100mL of deionized water, dry in an oven at 105°C for 12 hours to obtain a modified activated alumina with high adsorption capacity for fluoride ions, which is sealed and stored for future use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com