Preparation method of peptide base material for meat products and flavored meat product prepared from peptide base material

A technology of meat products and base materials, which is applied in the direction of protein-containing food ingredients, meat/fish preservation with chemicals, and food ingredients as taste improvers, etc. It can solve the problems of affecting consumers' choice desire, dull color, rancidity of oil, etc. To achieve the effect of solving flavor deterioration, enhancing flavor, and improving flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

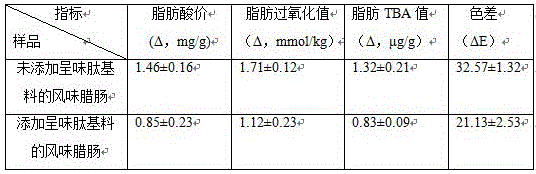

[0041] Example 1: flavored sausage

[0042] A preparation method of a taste-presenting peptide base material for sausage, comprising the steps:

[0043] a) After blanching the silkworm chrysalis that has removed pathogens and impurities with boiling water, add an appropriate amount of NaOH solution with a mass concentration of 0.1 wt% to adjust the protein content in the silkworm chrysalis to be 10 wt% for beating, and pass through a 60-mesh screen after beating to remove the silkworm chrysalis shells , obtain the silkworm chrysalis after the pretreatment, adjust the pH value to be 6.5, add the fatty acid hydrolase that accounts for 1wt% of the total mass of the silkworm chrysalis after the pretreatment, adjust the temperature to be 45 ℃ and carry out fat hydrolysis for 1.5 hours, to obtain the lipase enzymolysis product;

[0044] b) Adjust the pH value of the above-mentioned lipase hydrolyzed product to 8, and at the same time add the compound enzyme of 37071 enzyme and flavo...

Embodiment 2

[0057] Example 2: flavored dried meat

[0058] A preparation method for a taste-presenting peptide base material for dried meat, comprising the steps:

[0059] a) After blanching the tussah silkworm chrysalis that has removed pathogens and impurities with boiling water, add an appropriate amount of NaOH solution with a mass concentration of 0.1wt% to adjust the protein content in the silkworm chrysalis to be 10wt% for beating, and pass through a 40-mesh screen after beating to remove the silkworm chrysalis shells , obtain the silkworm chrysalis after the pretreatment, adjust the pH value to be 5, add the fatty acid hydrolase that accounts for 0.5wt% of the total mass of the silkworm chrysalis after the pretreatment, adjust the temperature to be 40 ℃ and carry out fat hydrolysis for 2 hours, to obtain the lipase enzymatic hydrolysis product;

[0060] b) Adjust the pH value of the above lipase hydrolyzed product to 7, at the same time add the compound enzyme of 37071 enzyme and ...

Embodiment 3

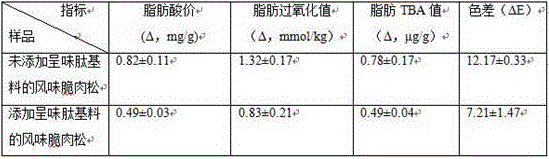

[0073] Example 3: Flavored Crispy Pork Floss

[0074] A method for preparing a taste-presenting peptide base material for crispy meat floss, comprising the steps of:

[0075] a) After blanching the silkworm chrysalis and the tussah silkworm chrysalis with a mass ratio of 1:1 to remove pathogens and impurities with boiling water, add an appropriate amount of NaOH solution with a mass concentration of 0.1wt% to adjust the protein content in the silkworm chrysalis to be 10wt% for beating. After passing through a 40-mesh sieve to remove the silkworm chrysalis shell, obtaining the silkworm chrysalis after the pretreatment, adjusting the pH value to be 8, adding the fatty acid hydrolase accounting for 2wt% of the total mass of the silkworm chrysalis after the pretreatment, and adjusting the temperature to be 50° C. to carry out fat hydrolysis for 1 hour, to obtain lipase hydrolysis products;

[0076] b) Adjust the pH value of the above lipase hydrolyzed product to 9, and at the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com