Micromolecule oil displacement agent with high viscosity increasing performance and high shearing resistance and preparation method thereof

A technology of small molecules and oil displacing agents, applied in the field of small molecule oil displacing agents and its preparation, can solve problems such as poor shear resistance, achieve high shear resistance, strong fluidity control ability, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

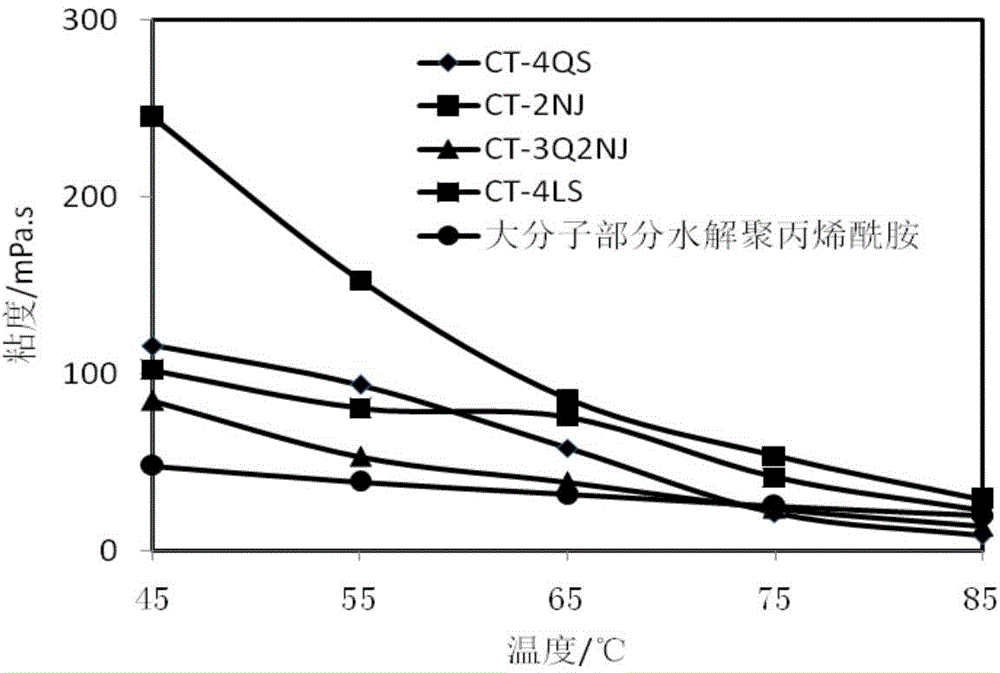

Embodiment 1

[0031] Raw materials: CTAB (cetyltrimethylammonium bromide), 4-hydroxysalicylic acid, anhydrous sodium carbonate, water with a salinity of 100±10mg / L.

[0032] Preparation steps:

[0033] (1) Weigh 0.375g of CTAB and add it to 49.5g of water with a mineralization degree of 100±10mg / L, raise the water temperature to 40±2°C, stir evenly, add 0.125g of 4-hydroxysalicylic acid, and stir evenly again , and adding anhydrous sodium carbonate to adjust the pH of the solution to be 4.10;

[0034] (2) Transfer the above mixture into a three-necked flask, heat with an oil bath while stirring, and keep the temperature at 68±2°C for 1 hour.

[0035] (3) After 1 hour, the viscosity increased, and the stirring was stopped, and the solution was poured out from the flask to cool, and finally a small molecule oil displacing agent CT-4QS with high viscosity was formed.

Embodiment 2

[0037] Raw materials: CTAB (cetyltrimethylammonium bromide), 2-naphthoic acid, anhydrous sodium carbonate, water with a salinity of 5380±50mg / L.

[0038] (1) Weigh 0.46g of CTAB and add it to 49.4g of water with a salinity of 5380±50mg / L, raise the water temperature to 45±2°C, stir evenly, add 0.14g of 2-naphthoic acid, stir evenly again, And adding anhydrous sodium carbonate to adjust the pH value of the solution to 6.5.

[0039] (2) Transfer the above mixture into a three-neck flask, heat with an oil bath while stirring, and keep the temperature at 63±2°C for 1.5 hours.

[0040] (3) After 1.5 hours, the viscosity increased, and the stirring was stopped, and the solution was poured out from the flask to cool, and a small-molecule oil-displacing agent CT-2NJ with high viscosity was finally formed.

Embodiment 3

[0042] Raw materials: CTAB (cetyltrimethylammonium bromide), 3,7-dihydroxy-2-naphthoic acid, anhydrous sodium carbonate, water with a salinity of 7950±50mg / L.

[0043] (1) Weigh 0.55g of CTAB and add it to 49.3g of water with a mineralization degree of 7950±50mg / L, raise the water temperature to 48±2°C, stir well, then add 0.15g of 3,7-dihydroxy-2-naphthalene Formic acid, stir again, and add sodium carbonate to adjust the pH value of the solution to 6.9.

[0044] (2) Transfer the above mixture into a three-necked flask, heat with an oil bath while stirring, and keep the temperature at 65±2°C for 2 hours.

[0045] (3) After reacting for 2 hours, the viscosity rises, stop stirring, and pour the solution out of the flask to cool, and finally form a small molecule oil displacing agent CT-3Q2NJ with high viscosity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com