Basic construction method for combined mold

A technology of foundation construction and combined molds, which is applied in the field of construction, can solve problems such as changing reasonable stress systems, hazards, non-compliance with specification requirements, and structural construction requirements, and achieve the effects of reducing human labor, simple operation, and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

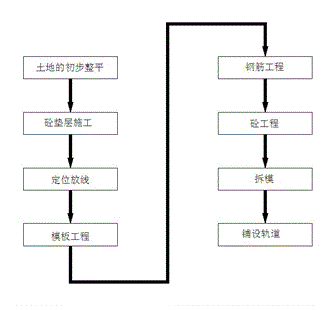

[0015] The following is a further description in conjunction with the construction flow chart.

[0016] As shown in the figure, a combined mold foundation construction method includes the following steps: step S101, preliminary leveling of the land, and removing unevenness on the ground.

[0017] Step S102, constructing the concrete cushion, pouring and tamping after the formwork is supported, and vibrating and tamping with a flat vibrator. Ensure that the thickness and strength of the cushion layer meet the design requirements; attention should be paid to maintenance after the concrete is poured, and it is advisable to cover it with plastic film within 12 hours of watering to keep the concrete surface moist. It should be cured for 5-7 days at room temperature.

[0018] Step S103, positioning and setting out the line, performing setting out and retesting according to the drawing axis and construction requirements, and marking on the ground to ensure the correct position.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com