Direct-current transmission converter valve assembling height adjusting device

A technology of assembly height and direct current transmission, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems that the reliability and production capacity of the converter valve module cannot be met, and it is difficult to control the assembly accuracy of the converter valve module. , to achieve the effect of being beneficial to physical and mental health, simplifying the assembly process, and reducing the difficulty of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

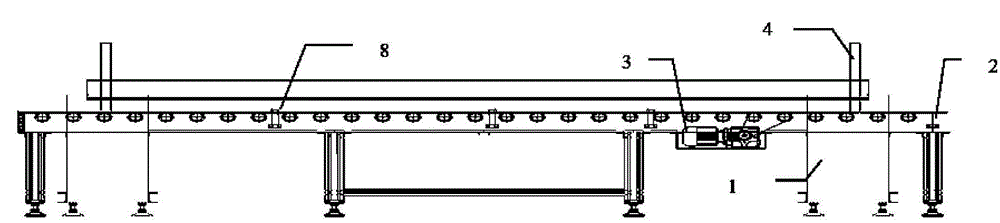

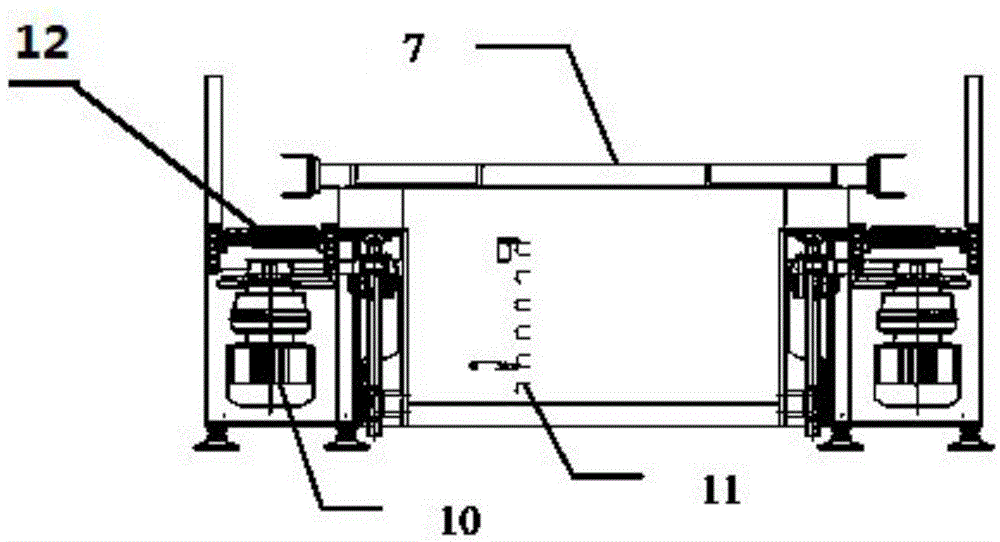

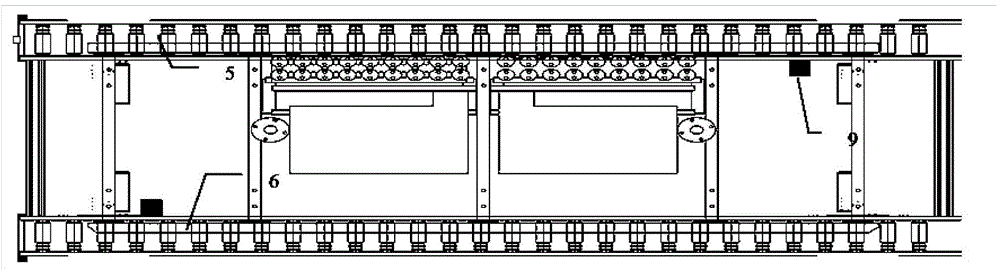

[0023] The invention provides a device for adjusting the assembly height of a direct current transmission converter valve, such as figure 1 As shown, it is the front view of the assembly height adjustment device of the DC transmission converter valve; it consists of the lifting mechanism 1, the positioning sensor 2, the control system 3, the safety protection grating 4, the transmission line body A 5, the transmission line body B 6, and the positioning guide column 8. The emergency stop switch 9, the deceleration mechanism 12, the travel switch 11, and the elevator 10 are composed.

[0024] The DC transmission converter valve assembly height adjustment device provided by the present invention also includes a rectangular frame body parallel to the ground; the two sides of the frame body are provided with a transmission li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com