A connection structure of copper bar of wind power inverter contactor

A connection structure and contactor technology, applied in the configuration/arrangement of fuses, panel/switching station circuit devices, substation/switching device boards/panels/desks, etc., can solve the danger of occurrence, contactor damage, and its own flexibility It is easy to cause problems such as shape changes, so as to achieve the effect of maintaining distance, reliable connection and avoiding cross influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

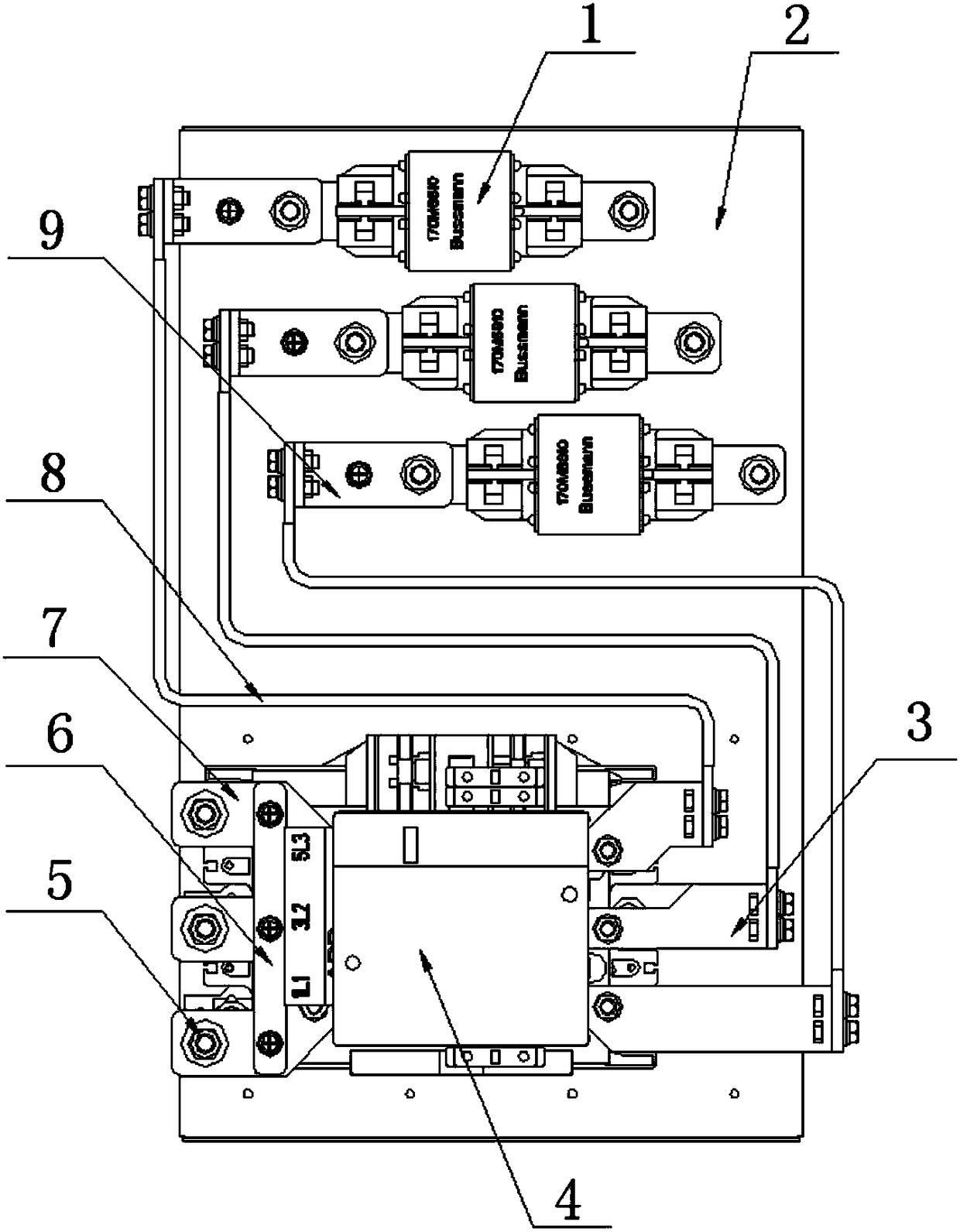

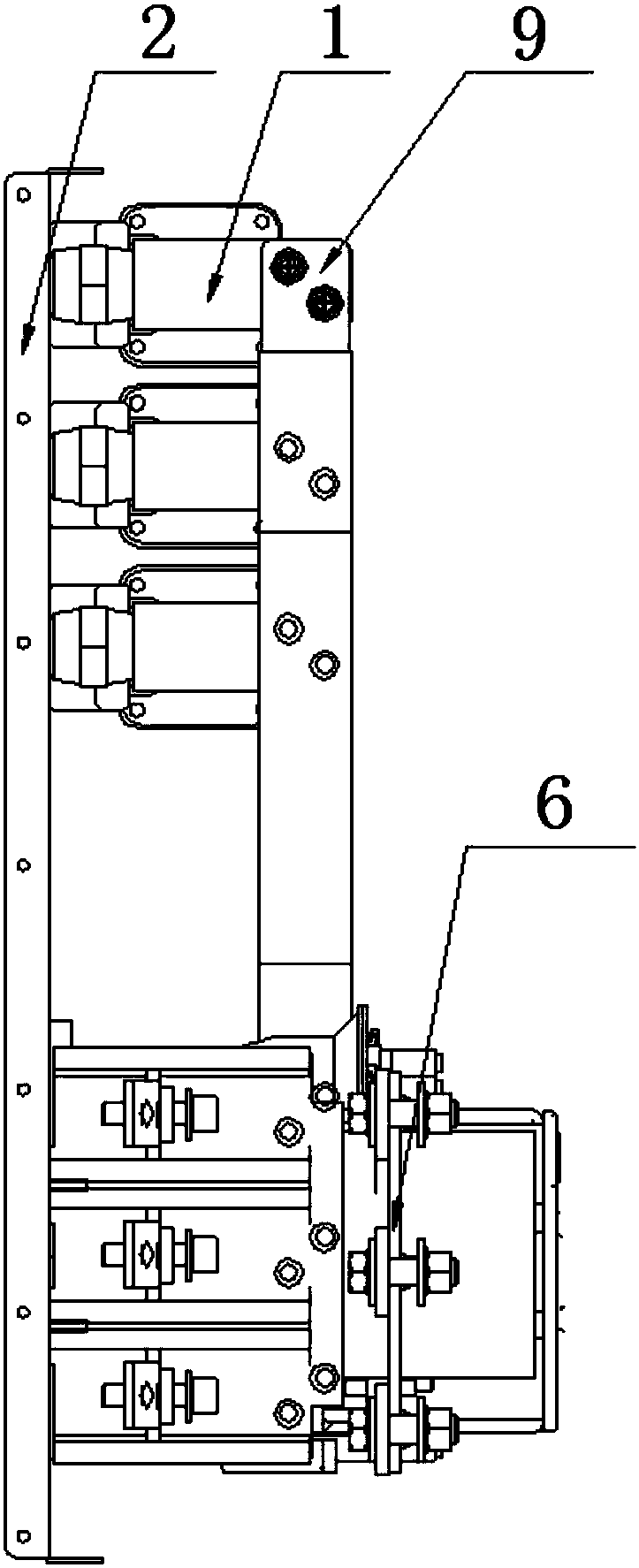

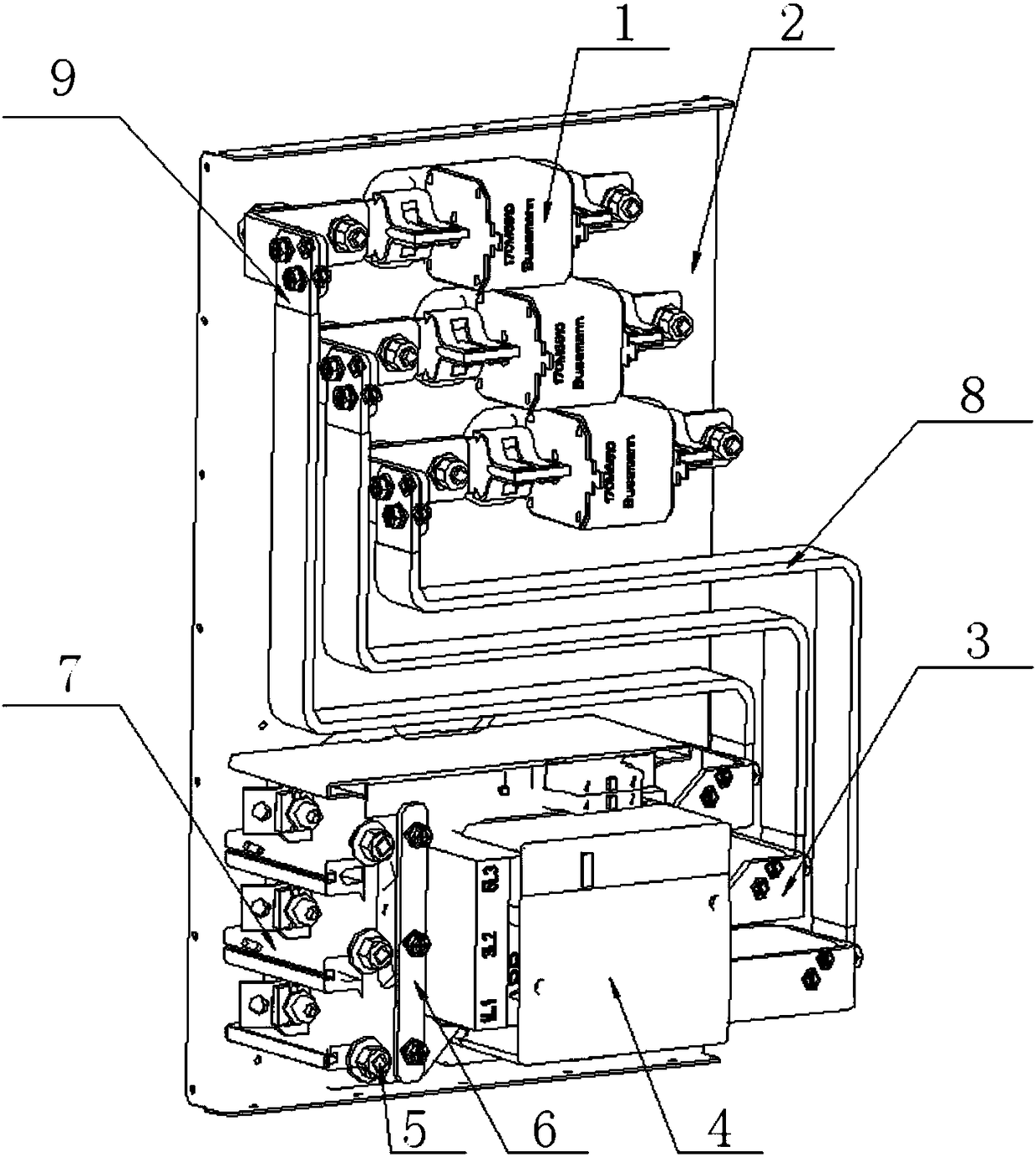

[0025] A copper bar connection structure for a wind power frequency converter contactor, comprising a contactor 4 and a vertical plate 2, the contactor is fixedly installed on the vertical plate, one side of the contactor is a three-phase input terminal 3 arranged horizontally, and the other side of the contactor One side is the three-phase output terminal 7 arranged horizontally. The innovation is that the three-phase output terminals are jointly installed with a vertical insulating frame plate 6, and the insulating frame plate and the three-phase output terminals are connected and fixed by bolts 5. The spacing between the three-phase output terminals can be reliably guaranteed, and contact accidents will not occur due to the deformation of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com