Snow depth measurement method based on image contrast

A measurement method and image comparison technology, which is applied in image enhancement, image analysis, and measurement devices, can solve problems such as large influence of temperature and wind speed, measurement errors, time-consuming and labor-intensive problems, and achieve the effect of improving accuracy and reducing the number of false alarms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

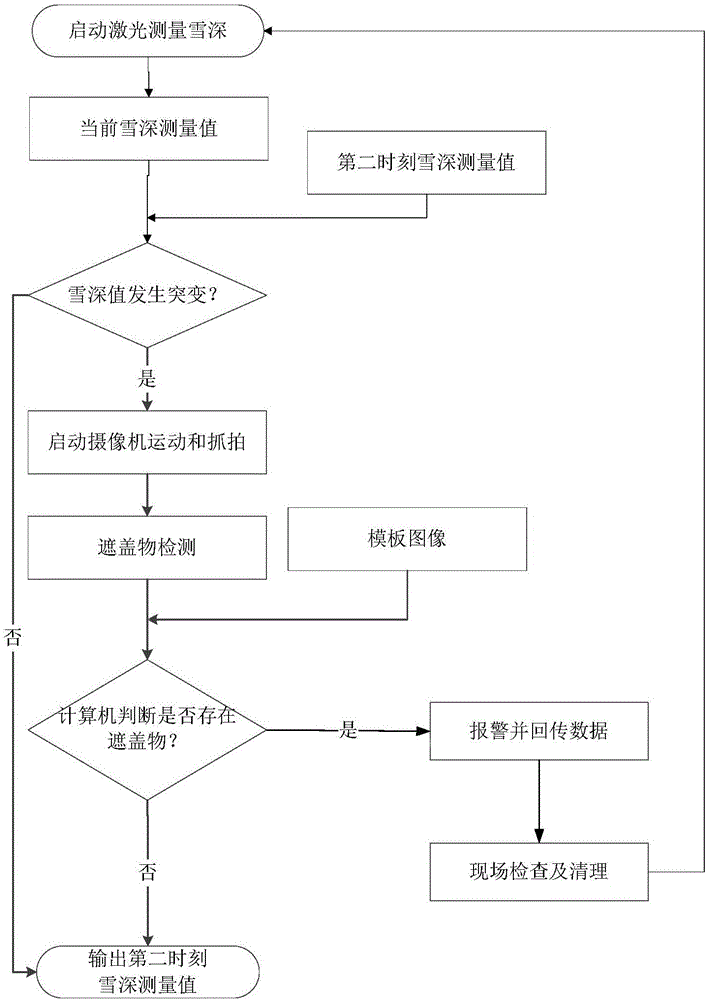

[0012] The method for detecting coverings based on image comparison in the present invention comprises the following steps:

[0013] (1) Start the laser to measure the snow depth, and record the current measurement value as the first measurement value;

[0014] (2) After 1 minute, start the laser again to measure the snow depth, and record the measured value as the second measured value;

[0015] (3) Compare the first measurement value with the second measurement value, if the difference between the two is greater than 5mm, it is determined that the measurement value has a sudden change, and enter step (4), if the difference between the two is less than the threshold value, then enter step (6);

[0016] (4) Determine whether there is a cover in the measurement area that causes a sudden change in the measurement value: start the camera movement and capture the measurement area, compare the captured measurement area image with the measurement area template image, and determine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com