Peak clipping and valley filling servo driving method system used in oil field oil pumping machine

A servo-driven, peak-shaving and valley-filling technology, which is applied in the program control and electrical program control of the sequence/logic controller, can solve problems such as power consumption adjustment, reduce power supply pressure, reduce labor intensity, and improve scientific research. Effects of management level and efficiency of mechanical oil recovery system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described more fully hereinafter with reference to the accompanying drawings, in which exemplary embodiments of the invention are illustrated.

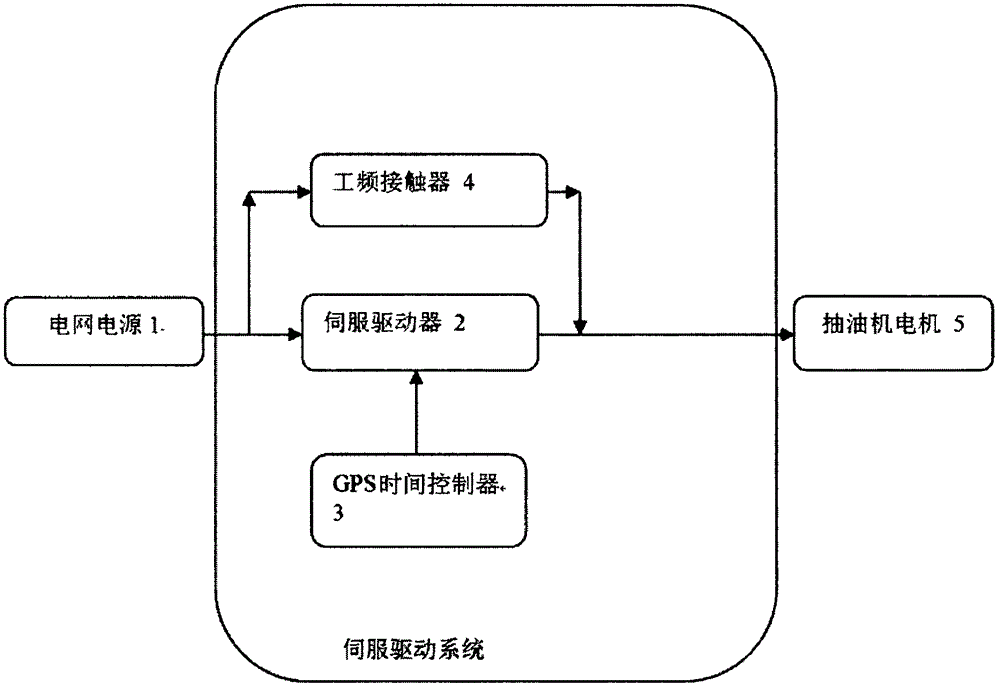

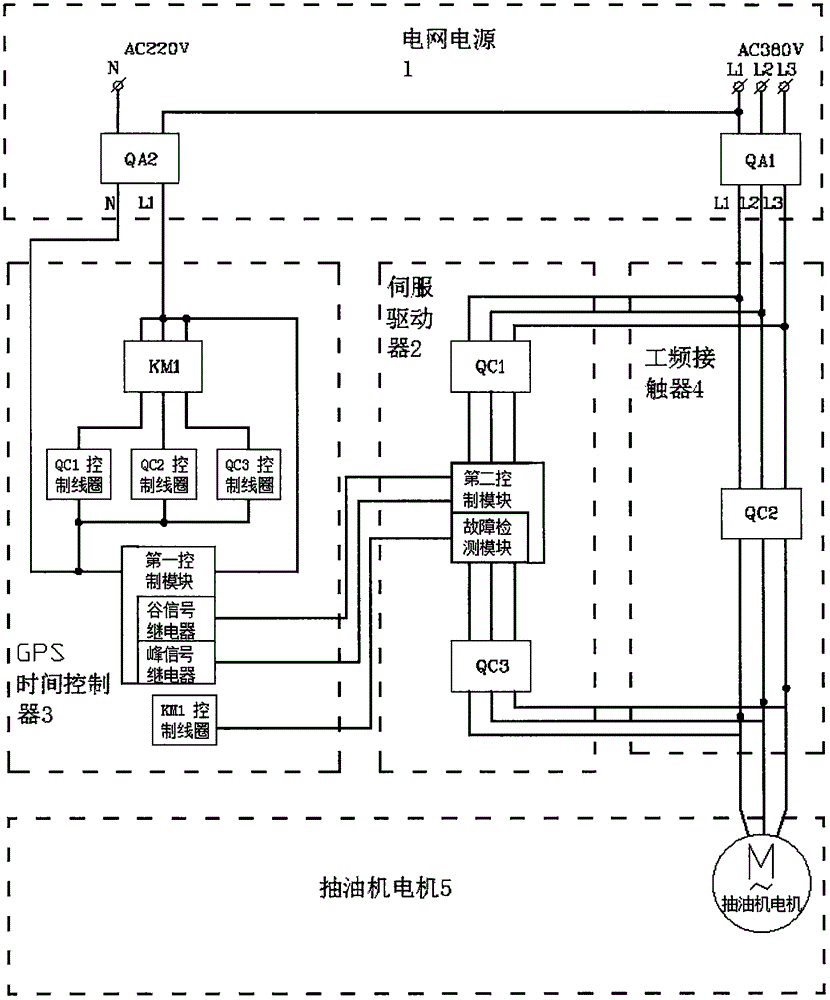

[0041] like figure 1As shown, the grid power supply 1 supplies power for the peak-shaving and valley-filling servo drive method system for oil field pumping units, which provides a three-phase AC 380V power frequency (50Hz) power supply, and the voltage and frequency of the grid power supply 1 are adjusted by the servo driver 2 through the servo driver 2. Adjust according to the preset parameters, and then output the adjusted power to the pumping unit motor 5 to drive the pumping unit to work.

[0042] The servo drive method system for peak cutting and valley filling of oilfield pumping units provided by the present invention includes a servo driver 2, a GPS time controller 3 and a power frequency contactor 4, wherein:

[0043] The GPS time controller 3 outputs the peak period signal, the valley p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com