Automatic medicine tablet packaging quality monitoring system

An automatic monitoring system and tablet technology, applied in measuring devices, material analysis by optical means, instruments, etc., can solve the problems of high cost, low efficiency of manual visual sorting of defective tablets and packaging, high labor intensity, etc. Fast and reliable separation, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

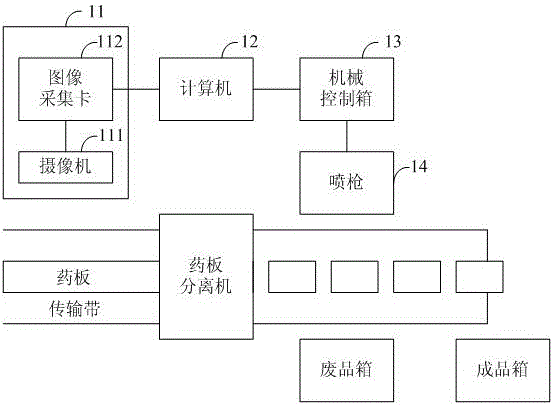

[0020] figure 1 It is a structural schematic diagram of the automatic monitoring system for tablet packaging quality in this embodiment. The automatic monitoring system for tablet packaging quality includes an image acquisition device 11 , a computer 12 , a mechanical control box 13 and a spray gun 14 .

[0021] Specifically, the tablet separator is installed in the middle of the tablet packaging conveyor belt, which divides the conveyor belt into two areas: the detection area and the separation area. Wherein, the conveyor belt in the detection area transports unseparated drug sheets, the conveyor belt in the separation area transfers separated drug sheets, and the end of the conveyor belt in the separation area is provided with a finished box. The image acquisition device 11 is installed on one side of the conveyor belt, and is used to capture images of unseparated medicine plates on the conveyor belt. Further, the image acquisition device 11 includes a camera 111 and an ima...

Embodiment 2

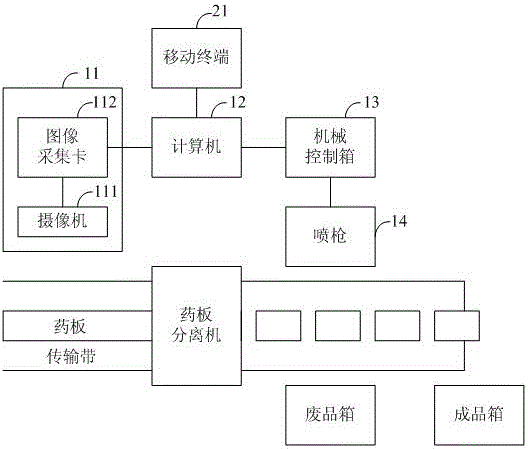

[0027] figure 2 It is a schematic structural diagram of the automatic monitoring system for tablet packaging quality in this embodiment. Compared with Embodiment 1, this embodiment differs in that it also includes a mobile terminal 21 that communicates with the computer 12 . By setting the mobile terminal 21, the computer 12 can send the production information, such as the number of tablet packaging defects and the rate of defective products, which it has counted by itself to the mobile terminal, so that the production management personnel can grasp the data in the production process anytime and anywhere.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com