Stratified sampling system

A sampling system and sampling tube technology, applied in sampling, analyzing materials, sampling devices, etc., can solve the problems of limited maximum depth, high production cost, complex structure, etc., and achieve the effects of precise control, accurate layering, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

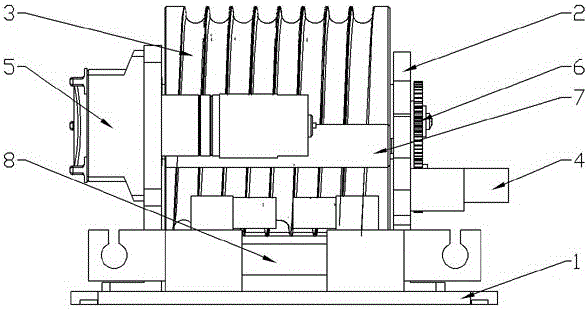

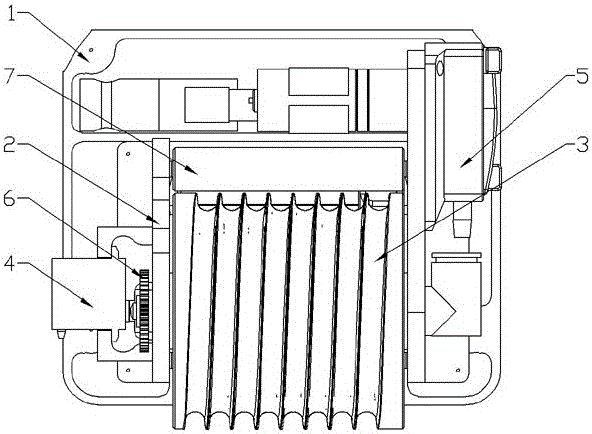

[0015] Such as figure 1 and figure 2 As shown, in this embodiment, the present invention includes a base 1 and a support frame 2 installed on both sides of the base 1, a spiral roller 3 is installed between the support frames 2, and the spiral roller 3 is provided with A sampling tube suitable for the spiral roller 3, the outer end surface of the support frame 2 is provided with a servo steering gear 4 connected to the spiral roller 3, and the spiral roller 3 is provided with a Connected with the vacuum rotary joint, the vacuum rotary joint is a device that transmits compressed air, hydraulic oil, water, grease and other media in a rotating state. The base 1 is also provided with a vacuum rotary joint that communicates with the vacuum rotary joint A peristaltic pump 5, the peristaltic pump 5 is provided with a water outlet, and the water outlet is provided with an outlet pipe.

[0016] In this embodiment, the layered sampling system further includes a gear 6, the gear 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com