Safety protection system and method for coal bed gas drilling machine engine

A safety protection and engine technology, which is applied in the direction of machine/engine, engine components, engine control, etc., can solve the problems of complex protection system and poor engine safety protection, and achieve the effect of high safety, rapid action and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

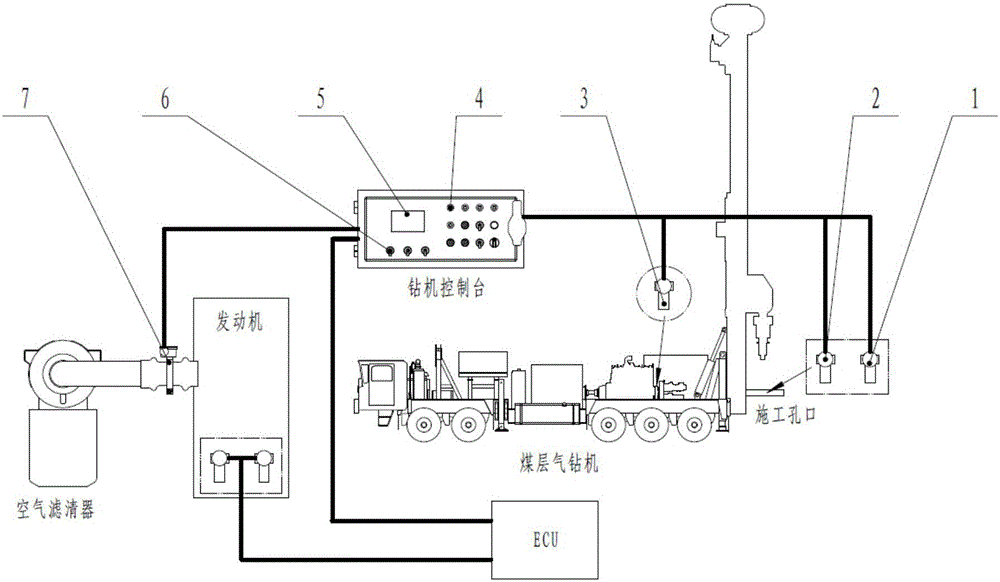

[0028] like figure 1 , a coalbed methane drilling rig engine safety protection system of the present invention, the system is provided with a combustible gas sensor 1, a toxic gas sensor 2, a rotational speed sensor 3, an audible and visual alarm lamp 4, a controller 5, an emergency stop switch 6 and an electromagnetic shut-off valve 7. The combustible gas sensor 1 and the toxic gas sensor 2 are installed at the construction hole of the drilling rig, the speed sensor 3 is installed on the engine flywheel or generator, the electromagnetic shut-off valve 7 is installed behind the engine air filter, the controller 5, and the sound and light alarm lamp 4 and the emergency stop switch 6 are integrated together and installed on the console of the drilling rig.

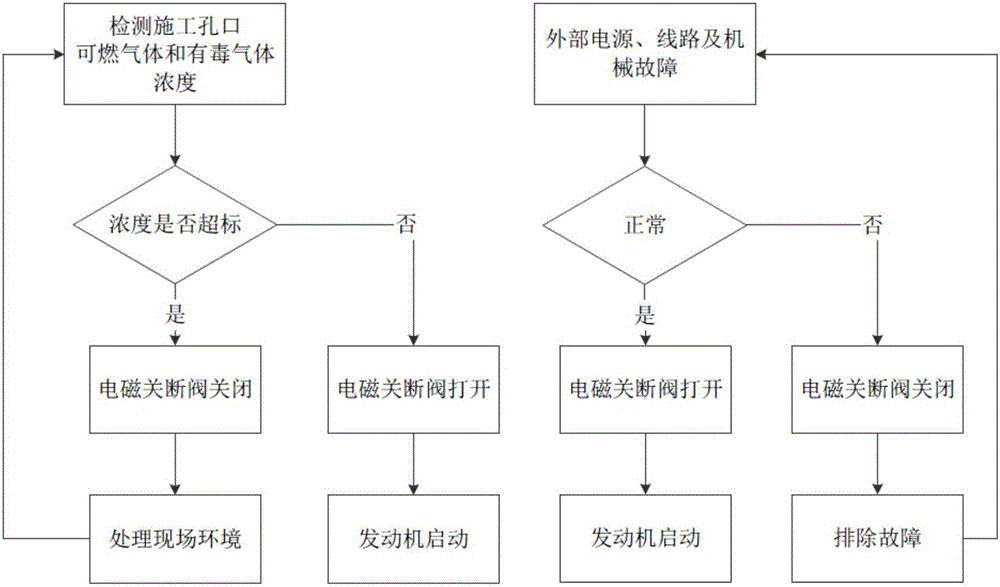

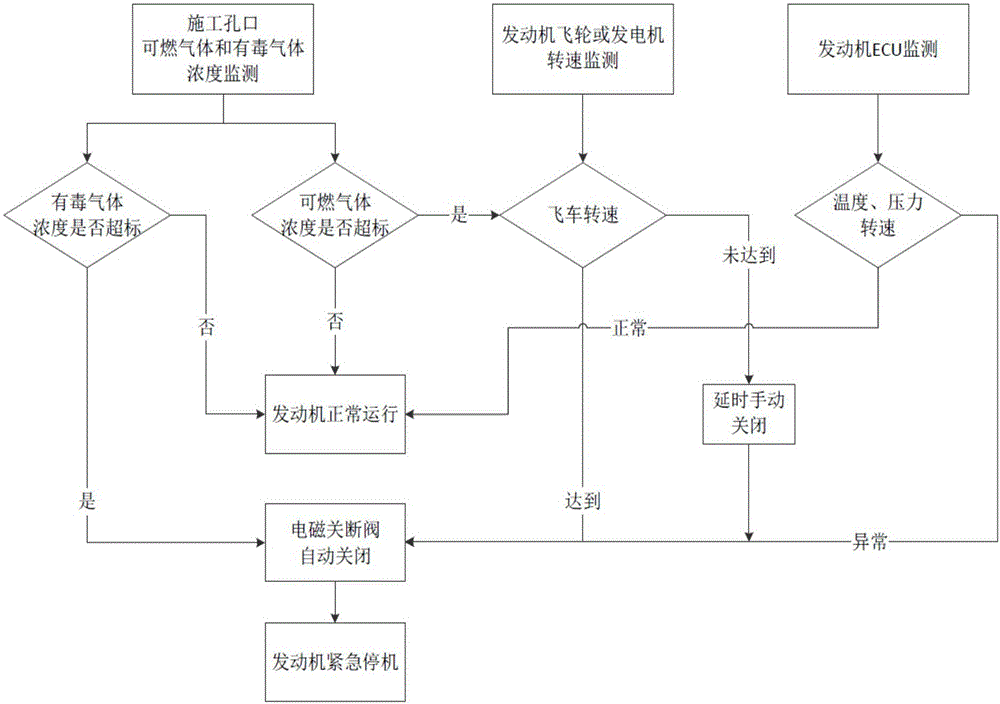

[0029] like figure 2 , before the engine starts, the opening of the electromagnetic shut-off valve 7 depends on the monitoring status of the dangerous and toxic gas concentration at the construction orifice by the combust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com